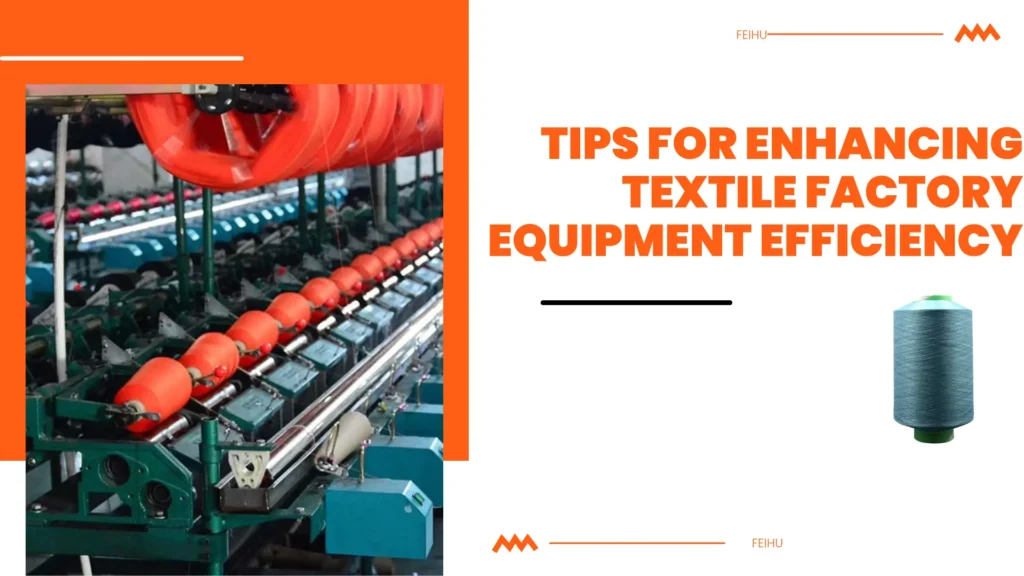

Textile industry holds an important role in the global economy. Vital for the production of a wide variety of goods. These range from clothing to industrial fabrics. But it faces significant hurdles.

Such as volatile raw material prices. There’s also an uptick in competition from abroad. Not to mention a growing demand for sustainable practices.

To successfully navigate these challenges. Textile manufacturers must give priority to equipment efficiency.

Efficient machinery not only curtails operational costs. It also amplifies the quality of the product. Plus, it improves overall productivity. This article provides concrete suggestions.

They aim to boost equipment efficiency in textile factories. This will ensure long-lasting success in a demanding market.

Learn More:

- Lean Manufacturing Principles and Winding Efficiency

- Employee Training and Development in Winding Processes

- Quality Control in Winding Processes

Understanding Equipment Efficiency

What Does Efficiency Mean?

Overall Equipment Effectiveness (OEE)

This metric merges three crucial elements. These are availability performance and quality. It offers a comprehensive view. It shows how effectively a manufacturing operation is used.

If OEE is high it implies something. Equipment is not just operational. It also produces high-quality products. Moreover it operates at the expected speed.

Downtime

Duration and frequency of machine downtime are critical. Tracking the duration and frequency of the two is included. These are scheduled maintenance and unscheduled breakdowns.

Manufacturers can identify patterns by analyzing downtime data. They can further take proactive steps. The aim is to minimize interruptions.

Production Yield

Production Yield measures the quantity of finished products. This is compared to the count of defective items.

A high yield suggests efficient operation of machinery. This machinery is producing quality outputs. This is crucial for maintaining profitability.

Why Efficiency Matters

Impact on Production Costs

Machinery that works efficiently uses less energy and cuts back on waste. This provides substantial savings. It also cuts down on production expenses. As a result it benefits manufacturers.

These savings permit them to offer prices that are competitive. This is very important. It helps in securing market share.

Relationship Between Efficiency and Product Quality

A strong correlation exists. This comes between machine efficiency and product quality. Maintained efficiently machines produce few defects. This ensures that products meet quality standards that are stringent.

High quality outputs lead to greater customer satisfaction. It also leads to lower return rates. Both of these can impact a company’s bottom line significantly.

Regular Maintenance Practices

Importance of Routine Check-Ups

Increased Lifespan

Regular maintenance can save manufacturers a considerable amount of money over time. It’s a proactive way of addressing potential problems before they become a significant issue.

Manufacturers should consider making regular maintenance part of their standard operation procedures. It can save them from the expenses associated with unexpected machinery breakdowns.

Overall, regular maintenance is beneficial to both the manufacturer and the employees. It’s an essential part of creating a safe and efficient working environment.

Consistent Performance

Well-maintained equipment functions at a higher rate. Fewer disruptions occur in production.

Consistent performance here is important. It assures meeting production scheduling. It guarantees fulfilling customer requests. It does without delays.

Safety

Regular inspections help identify safety hazards. A safer working environment for employees gets ensured.

Potential safety issues get addressed. This protection safeguards workers. It also minimizes risk of costly accidents. It minimizes liabilities.

Tips for Effective Maintenance

Creating a Maintenance Schedule

This should incorporate regular tasks. Tasks such as inspections and cleaning should be included. Also, replacements for parts should be considered.

A well-ordered approach is vital. It helps to guarantee nothing is missed. It also helps maintenance to be systematically carried out.

Training Staff for Basic Upkeep

Prepare your staff with the know-how to manage standard maintenance tasks. Training can assist employees to pinpoint minor problems before they worsen. This nurtures a cultural atmosphere of preventive care.

This approach doesn’t just boost the longevity of equipment. It also promotes a sense of responsibility among the staff.

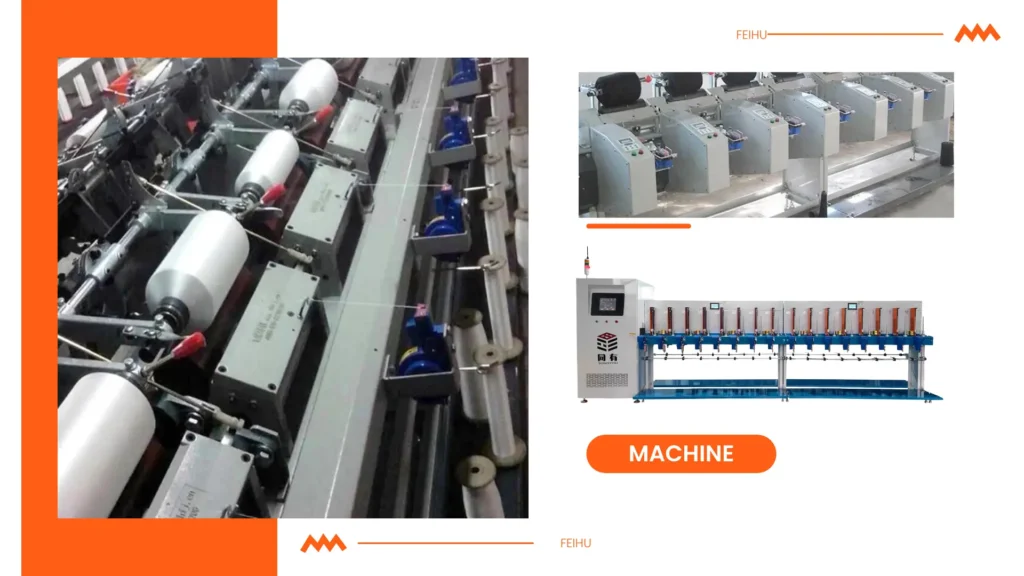

Upgrading Technology

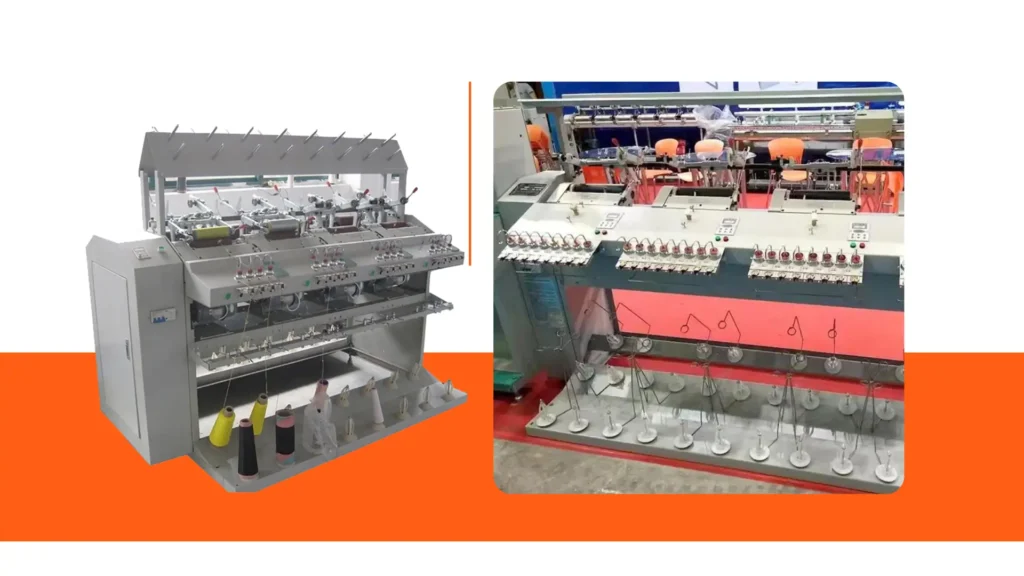

Benefits of Modern Equipment

Enhanced Speed and Accuracy

New machinery often operates with increased speed and accuracy. It reduces production time and enhances product quality.

For example automated cutting machines. They can achieve higher accuracy than manual cutting. This results in less fabric waste.

Energy Efficiency

Machines of today are usually designed to utilize less energy. This leads to lower utility costs and a reduced environmental impact.

Energy efficient equipment not just lowers operation costs. It also falls in line with the increasing consumer desire for sustainable practices.

Evaluating Technology Needs

Assessing Current Equipment Limitations

Pinpoint definite areas. Areas where there are deficiencies with current equipment.

Do we see regular breakdowns? Does the equipment not keep tempo with production requests? Understanding these deficiencies is crucial. It underpins decisions to upgrade.

Identifying Gaps That New Technology Can Fill

Determine whether new technology can solve specific operational challenges. Consider this instance: if the issue rests on production speed investment in quicker machinery can be essential.

On the other hand, if quality is deficient precision technology may be the solution.

Employee Training and Development

Importance of Skilled Operators

Operational Efficiency

Operators who are well-versed comprehend the complexities of machines they handle.

This comprehension allows for optimal settings. These settings cater to various materials and products. As a result operations become more efficient.

Trained operators possess the ability to quickly pinpoint and deal with minor issues.

It happens before they snowball into big problems. This minimizes downtime. In addition, maintenance of production flow is maintained.

Troubleshooting Skills

The transmission of knowledge and expertise of machines is key. It is key for operators to make the best use of machines. But the key doesn’t always open doors.

In the case of well-trained operators, they do optimize the settings of machines.

They do it for varying materials and products making our operations more efficient.

The operators understand the complexities of the machines they operate. This understanding is vital for efficiency.

When problems arise, it is also the operators who come to the rescue. They quickly identify and handle minor issues.

They do this before they worsen. It prevents major problems from occurring.

Trained operators keep the downtime to a minimum. They also ensure a seamless operation.

Training Programs to Consider

Technical Skills Training

Emphasize on operation of machines maintenance, is crucial. Also, we must focus on troubleshooting. This is to ensure that employees can skillfully handle equipment.

The training ought to be practical. It should be personalized to specific machinery found in the factory.

Ongoing Education for Staff

Support continuous learning. Make use of workshops seminars. Keep staff informed about the latest technologies and best practices. This can lead to increased performance.

It can also result in innovative thinking.

Provide resources for professional development. This can aid in retaining skilled employees.

Streamlining Production Processes

Analyzing Workflow

Mapping Production Steps

Begin by crafting visual display of production process. This uncovers delays and duplicate steps.

Mapping facilitates pinpointing where to streamline workflow. This aids in the minimization of wasted time.

Implementing Standard Operating Procedures (SOPs)

When SOPs are established adherence becomes the norm. This is a good thing. It leads to improved efficiency and standardization across teams. It results in shorter training periods for new employees.

There are fewer errors due to miscommunication. Time is not wasted on ‘reinventing the wheel’. SOPs ensure that you are always following industry’s best practices.

This is especially important in areas with high compliance standards. SOPs provide a safety net. They reduce the margin of error and minimize risk.

They can’t prevent disasters but they can certainly lessen them. SOPs are the backbone of any successful organization’s day-to-day operations. Without them, chaos would ensue.

Lean Manufacturing Principles

Minimized Waste

Process analysis helps manufacturers cut unneeded steps. They also decrease material waste.

This results in cost reduction. It also aids in sustainability endeavors.

Increased Productivity

Refined procedures lead to swifter production periods. They also produce higher output rates.

Lean principles signify continuous improvement. This spurs manufacturers to assess operations. They refine them on a regular basis.

Implementing Automation

Advantages of Automation

Increase Production Rates

Machines can work nonstop. There is no tiredness. It results in higher output levels. Automation can cut down cycle times.

Manufacturers meet growing demand. Quality is not affected.

Improve Consistency

Automated processes are a key feature. They ensure consistency. Production is shaped by uniformity.

There is less variation. Defects are reduced. Maintenance of satisfaction of customers is maybe the most important role of consistent quality. Also, it helps in maintaining the brand reputation.

Choosing the Right Automation Solutions

Assessing Production Needs

You need to establish processes garnering most from automation. Furthermore you should determine how alignment with production goals occurs.

Complexities like production volume need thought. Consideration should be given to potential error reduction.

Balancing Automation with Human Oversight

Automation boosts efficiency and human oversight is key. Human oversight is crucial for quality control.

It is also important in troubleshooting. The right balance is necessary. It is important between automated processes and experienced labor. This is crucial for upholding high standards.

Monitoring Performance

Importance of Data Analytics

Performance Dashboards

These are visual displays. They show machine performance metrics. The aim is to help managers make informed decisions.

Dashboards can give immediate feedback. They can provide an update on machine status. Or, they can provide information on production rates. Also, they can show quality metrics.

Predictive Maintenance Software

These are systems. They analyze data. The goal is to predict when maintenance is required.

The intention is to reduce unexpected downtime. By foreseeing maintenance needs, manufacturers can plan repairs. They can do this during convenient times. This action minimizes disruptions.

Adjusting Strategies Based on Data

Identify Trends

You should identify patterns. Trends may become evident in machine performance.

This way you make proactive adjustments. Let’s consider an example. If data indicates a decline in production speed.

This decline has occurred over time then it may reveal a need for maintenance. This is important for maintenance. Also, it should not be ignored.

Implement Case Studies of Successful Data-Driven Adjustments

Learn from examples of success. These are examples where data analytics led to efficiency gains. Especially gains of note.

An example is a concrete increase in efficiency. For instance, reducing downtime for machines. Or maybe even optimizing schedules for production.

These cases should be documented. Documenting these cases is important. It helps in creating a knowledge base. This is for future improvements. The improvements to come.

Sustainability and Efficiency

Eco-Friendly Practices

Cost Savings

Lessening squandering and consumption of energy is able to bring about lesser operating expenditures.

Imagine for instance, putting funds in energy-efficient equipment could mean having to pay a high initial cost at the beginning. However in the long term it offers significant savings.

Enhanced Market Appeal

Public is more and more drawn to brands that are sustainable. This can lead to more sales.

Companies who adopt eco-friendly practices often find they can make themselves different in market that is crowded.

Compliance with Regulations

Streamlined Operations

Regulatory guidelines often require process improvements. These can enhance overall efficiency.

Compliance can actually drive innovation. Manufacturers search for new ways to meet the standards. They do this while optimizing production.

Access to Incentives

Numerous regions give financial incentives. They reward companies adopting sustainable practices.

They provide extra motivation for compliance. Incentives can defray the costs of equipment upgrades. They can also make it easier to put into practice eco-friendly methods.

Conclusion

Heightening equipment efficiency in textile production is pivotal. It maintains competitiveness in a challenging market.

Regular maintenance practices have to be enforced. The technology constantly requires upgrading. Investment in employee training is essential. Streamlining production processes is key. Automation is to be embraced.

This can lead to significant enhancements in manufacturer’s operations. Performance monitoring is important.

Sustainable practices need to be adopted. This can result in extra efficiency gains.