In the current competitive manufacturing field it is vital to reduce downtime. Reducing downtime matters for success.

Downtime is when production stops. Various issues can lead to these periods. Downtime is significant. It can affect the company’s earnings. In this text we will discuss successful tactics.

These strategies aim to reduce downtime in production. The goal is to help businesses.

Learn More:

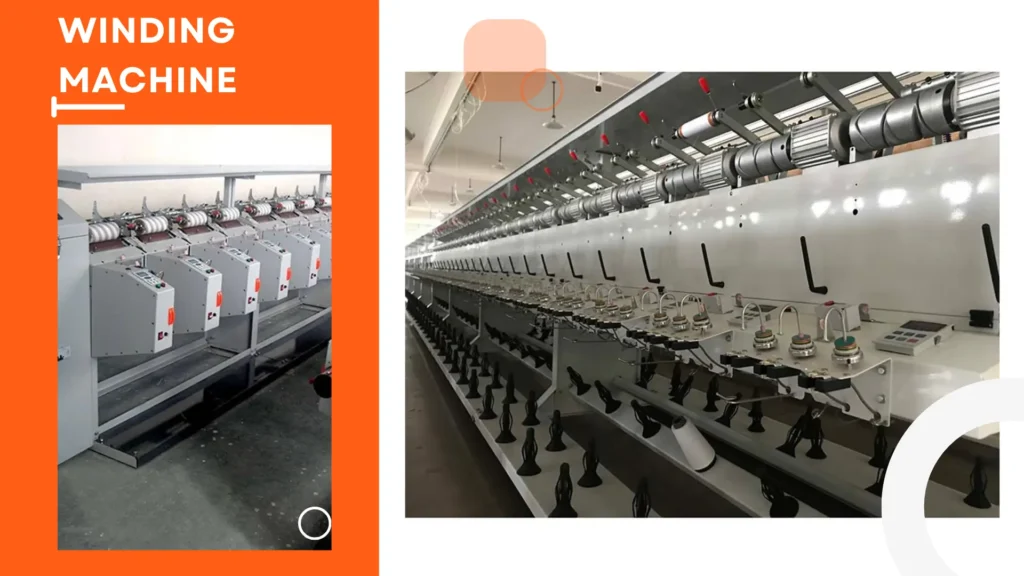

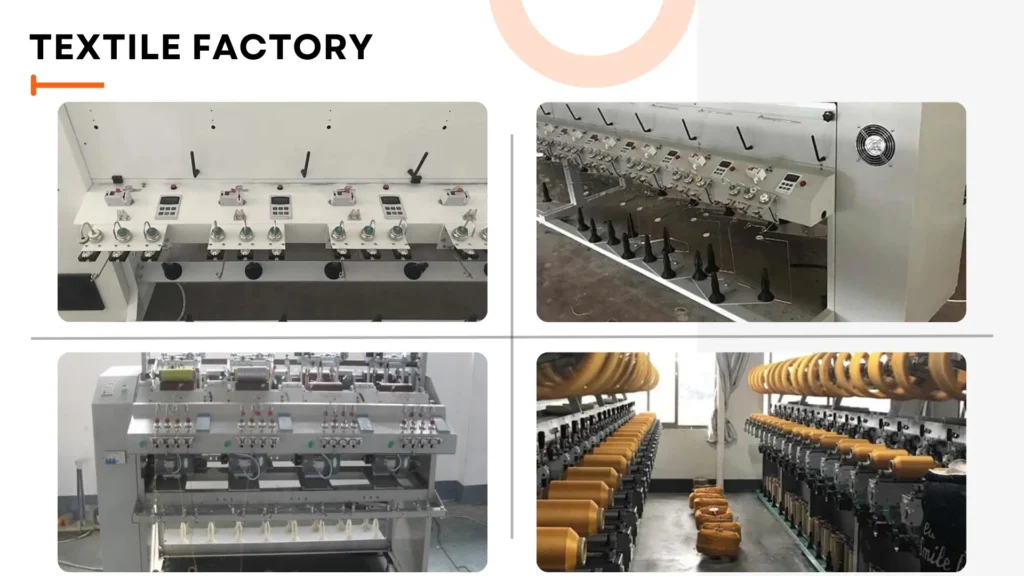

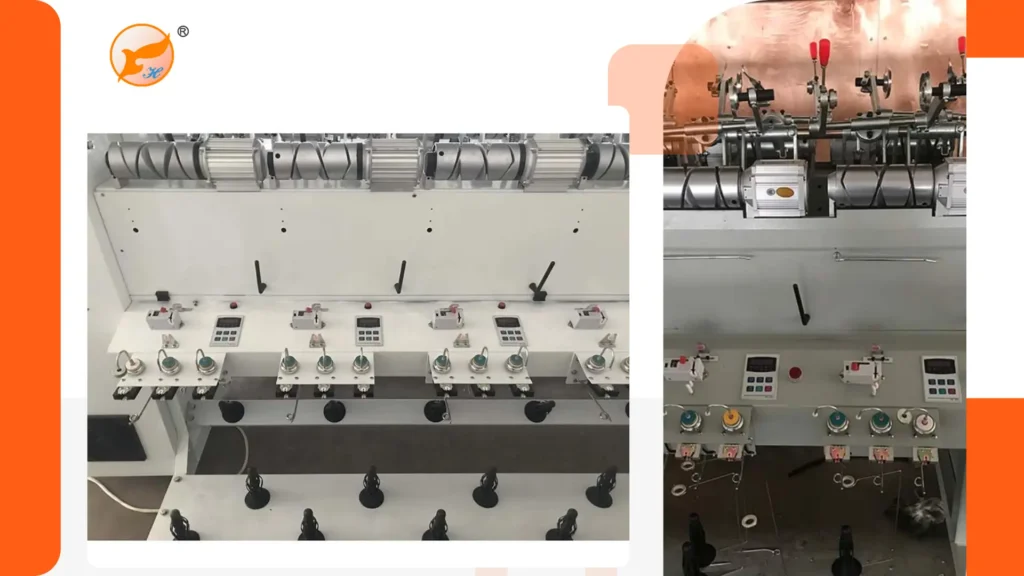

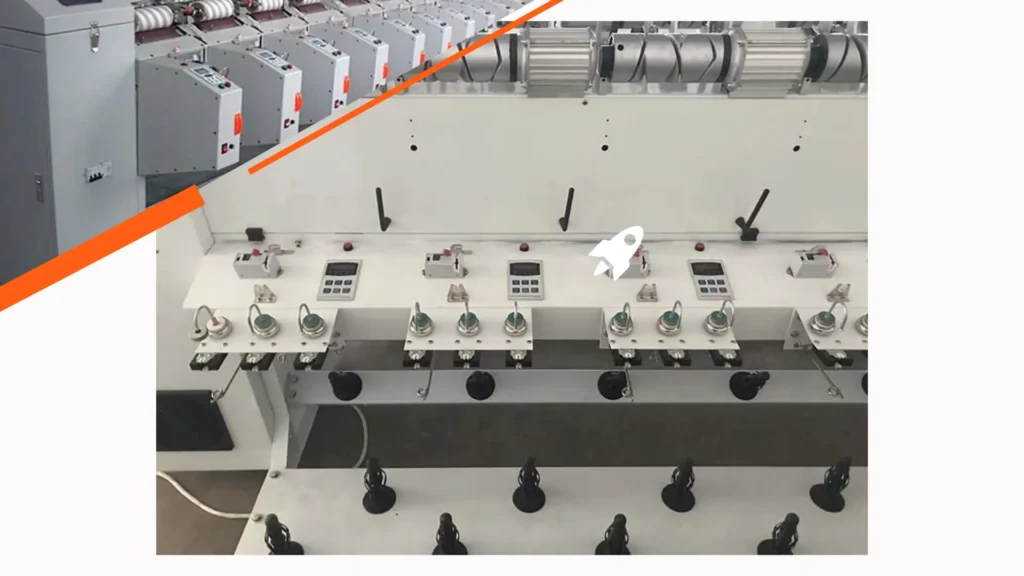

- Comprehensive Guide to Sourcing Automatic Winding Machines from China

- Cost-Effective Strategies for Buying Automatic Winding Machines from China

- Improving Winding Efficiency in Textile Factories

Understanding Downtime

Types of Downtime

Planned Downtime

These are for maintenance or upgrades.

While required this downtime can still create issues. It may disrupt production schedules.

Communicate about these times is vital. Communication is key to minimize impact.

Unplanned Downtime

It may be due to equipment failures.

It could also stem from power outages or unforeseen events. Unplanned downtime can be quite harmful.

It can bring about immediate production delays. It can even result in financial losses.

Importance of Minimizing Downtime

Any time not spent producing is time wasted. Secondarily reducing downtime leads to significant cost savings.

It can also improve employee morale and enhance customer satisfaction. Businesses can maintain a strong market reputation when production runs smoothly.

Impact of Downtime on Business

Effects on Production Costs

Downtime can result in escalated production costs. This outcome is caused by squandered labor.

Resulting in financial losses. Labor costs continue to build up while production is suspended.

Setting aside materials for production that can later go to waste if they are not used in time is another challenge.

Long-Term Consequences for Competitiveness

Downtime often undermines company’s competitive edge. A company that constantly grapples with production pauses risks losing customers.

They may go to competitors who can deliver more reliably and efficiently.

Additionally, an untrustworthy image can discourage potential customers from associating with business.

Conducting a Downtime Analysis

Identifying Common Causes

Equipment Failures

Problems related to machinery result in sudden failures. Regular checks are effective in preventing these occurrences.

Mechanical problems and deterioration are common issues. Regular monitoring of equipment helps prevent these failures.

Inefficient Processes

Inadequate workflow design can result in delays. Delays can increase potential for downtime.

The act of analyzing these procedures is beneficial. It aids in identifying areas in need of improvement.

Importance of Data Collection

Gathering data on downtime occurrences is essential. It allows an understanding of trends and patterns. By analyzing this data manufacturers can identify specific problems.

Structured data collection is important. It assists in making informed choices. These decisions pertain to the area for improvement.

Tools for Analysis

Downtime Tracking Tools

Investment in downtime-tracking tools aids in monitoring the production line effectively.

They help in analyzing production interruptions. The tools are insights providers.

Companies see trends traced over time. These companies can identify frequent problems. They can focus on the most urgent solutions.

Implementing Effective Monitoring Systems

Creating surveillance systems offers businesses the ability to track equipment performance.

They can do this in real time. The early warning alert system helps to zero in on potential troubles.

This occurs before they expand into massive downtime. Systems are in place for immediate action should a fault arise. The impact of unexpected failures is thus lessened.

Implementing Preventive Maintenance

Benefits of a Scheduled Maintenance Program

Increased Equipment Lifespan

They extend the lifespan of machines. This delays costly replacements. This not only saves money. It also keeps production capacity steady.

Reduced Unexpected Breakdowns

Anticipatory actions can catch possible issues early. This reduces the chances of unforeseen downtime.

Actively looking out for potential problems helps. There is a consistent flow of production.

Key Components of Maintenance Checks

Inspections

Examining equipment regularly can detect issues before they lead to failure. Inspections on a schedule prevent oversights.

They are integrated into the production timeline.

Lubrication

Lubrication is important for preventing friction and heat increase. Simple but effective practice, prolongs equipment life. Raises efficiency levels.

Creating a Maintenance Schedule

Steps for Developing a Maintenance Plan

Assess Current Equipment

The understanding of the current equipment is vital. This understanding helps to prioritize needs. It helps to determine maintenance.

Determine Maintenance Frequency

Set how often each machine needs servicing. Base the frequency on use and maker suggestions. Different apparatus may require distinct maintenance plans.

Allocate Resources

This is for maintenance activities. A dedicated resource for maintenance helps. It keeps the production running smoothly.

Involving Staff in Maintenance Responsibilities

It can guarantee that all have awareness of equipment status. When employees embrace responsibility for maintenance, culture of care and rigor is fostered. This results in proactive actions for equipment upkeep.

Investing in Training and Development

How Training Reduces Downtime

Improved Troubleshooting Skills

Employees learn to identify and solve problems quickly. This is a skill that minimizes downtime.

Workers’ confidence in their abilities is crucial. They can address issues without needing outside help. That’s an efficiency dormant.

Enhanced Operational Efficiency

Staff can operate equipment effectively. This leads to smoother production.

Understanding machinery and workflows helps. Employees anticipate problems and mitigate them.

Benefits of Cross-Training Employees

Cross-training employees in multiple roles provides flexibility. It happens during staffing shortages or emergencies.

When workers are knowledgeable in various areas they can help. They help to maintain production continuity.

This adaptability can be crucial. It is so in high-pressure situations. In those situations every minute counts. Training Programs to Consider.

Training Programs to Consider

Types of Training to Improve Efficiency

Hands-On Training

Practical sessions allow employees to learn equipment operation directly. Experiential learning is often more effective.

It is more effective than theoretical instruction.

Safety Training

Ensuring workers understand safety protocols can prevent accidents. Those accidents can lead to downtime.

A safe work environment is crucial. It is crucial for maintaining productivity.

Ongoing Education for Skill Updates

Continuous training opportunities are vital. These ensure employees are current on tech and good practices.

That way the workforce stays skilled. They remain capable of handling changing production needs. Consistent workshops and seminars can encourage a learning culture.

Upgrading Equipment and Technology

Signs It’s Time to Upgrade

Frequent Breakdowns

When equipment fails now and then, one might consider a new one.

Looking into the frequency of problems may provide insight. This insight can help decide if repair costs are worth it.

Outdated Technology

Older machines could be less efficient than modern ones. Upgrading could lead to considerable enhancements. Both in the speed and productivity.

Indicators of Equipment-Related Downtime

Increased Maintenance Needs

Machinery that needs constant repairs could lead to more costs.

It might be more economical to invest in new technology. To identify patterns consulting maintenance records could be crucial.

Lower Production Output

Sometimes equipment cannot cope up with production demands. Need for upgrades may be necessary.

Assessing output can help. It can determine if productivity is held back by equipment.

Cost-Effectiveness of New Technology

Investing in new technology can lead to significant long-term savings. Modern equipment is often energy-efficient.

It is capable of higher output too. Reduction of operational costs is possible. Also, newer technologies may come with reliability-enhancing features. Features that enhance ease of use also exist.

Benefits of Modern Equipment

Advantages of Advanced Machinery

Increased Reliability

New machines are normally more dependable. This results in fewer setbacks. Steady production schedules are maintained due to this reliability.

Enhanced Efficiency

Advanced technology frequently includes automation. It also includes smart features that enhance production processes.

This enhanced efficiency often results in substantial cost savings. Over time the savings add up.

Examples of Technologies for Reliability

Predictive Maintenance Tools

Technologies include what are called predictive maintenance tools. They analyze equipment data.

The analysis allows them to predict failures before they happen. Maintenance activities are then planned proactively. This reduces unplanned downtime.

IoT Devices

Then there are IoT devices. These can monitor performance of equipment in real-time.

This means they provide alerts for possible issues. Quick responses to problems are possible.

Streamlining Production Processes

Analyzing Workflow Efficiency

It’s critical to review workflow processes consistently. Downtime can result from inefficiencies.

Comprehending these processes will show where betterments can be achieved. In other words you need to analyze the processes.

Techniques for Mapping Production Processes

Parsing flowcharts or process maps could offer improvements. By illustrating production steps these methods can help.

They also can identify areas in need of renovation. Processes are mapped out. It shows businesses they can streamline operations. This in turn, helps identify redundancies.

Identifying Bottlenecks and Inefficiencies

Labor Constraints

Critical points may not have sufficient staffing. This can slow down production.

It’s essential to ensure staffing levels are adequate. The goal is to minimize these delays.

Material Supply Issues

Delays in receipt of materials can stop the entire production line. Make reliable supply chain connections. By doing this we can mitigate this risk.

Implementing Lean Manufacturing Principles

Overview of Lean Practices

Lean manufacturing principles focus on the minimization of waste. At the same time, they concentrate on the maximization of productivity.

By embracing these principles, firms can simplify their operations. There is a reduction in disruption.

Lean methods often necessitate consistent tracking. They also require adjustments to workflows. This ensures maximum efficiency.

Creating a Culture of Continuous Improvement

Cultivating a culture of continuous improvement empowers staff members. They can pinpoint and remove inefficiencies.

These can step up productivity. This form of culture encourages an environment. It is an environment where everyone feels they play a part. They feel they are responsible for maintaining high standards.

Utilizing Automation

Minimizing Human Error

These mistakes result in delays. By replacing manual work with automation, companies can increase consistency and reliability. This ensures that production goes smoothly.

Types of Automation for Production Lines

Robotic Process Automation (RPA)

RPA can perform packing and sorting – things that require high volume.

The technique is done without fatigue. This results in increased throughput.

Automated Guided Vehicles (AGVs)

AGVs transport materials around a facility.

They do it without human intervention. This reduces need for manual handling. It also improves efficiency.

Choosing the Right Automation Solutions

Factors for Selecting Automation Equipment

Production Requirements

Look at the particular tasks needing automation. Different processes might demand diverse types of automation.

Budget Constraints

It’s crucial to check if chosen solutions fit in the business’ financial parameters. Compromise between cost and expected benefits is important.

Balancing Automation with Human Oversight

Yet human oversight is vital. It’s key for quality control. It is also essential for problem-solving.

Correct balance between the two optimizes production processes. It also ensures high standards are maintained.

Establishing Clear Communication

Preventing Misunderstandings

Clear communication decreases risk of misunderstandings. Misunderstandings could lead to production delays.

Establishing protocols for reporting issues can ensure everyone is on the same page. It also minimizes confusion and errors.

Tools for Improving Team Interactions

Collaboration Software

Utilize platforms enabling real-time communication. Also allow for project management.

These tools are effective for improving coordination. Response times can be significantly improved.

Regular Team Meetings

Consistent meetings schedule is important. It ensures team members are informed.

They’re made aware of production goals. They also understand the challenges. Regular check-ins are useful. They help maintain focus. There’s also a sense of accountability.

Monitoring Performance and Adjusting Strategies

Key Performance Indicators (KPIs)

Downtime Percentage

The downtime percentage is a measure. It quantifies the duration when production comes to a halt.

But the total operating time is the standard denominator in this case. Monitoring requires careful attention. This metric aids in observing trends.

Production Output

Assessing production output is vital. The amount of product produced in a given period is determined.

It enables the evaluation of efficiency. Associated effectiveness is also measured.

Tools for Real-Time Monitoring

Investment in systems for real-time monitoring can offer insights. Insights into production process.

They allow for immediate adjustments. These tools can detect issues early. They enable quicker responses to potential problems.

Adapting Based on Data

Informed decisions improve productivity. These decisions are based on data. People often review performance metrics.

It helps identify trends. Strategies are adjusted accordingly. This ensures continuous improvement.

Case Studies of Successful Strategies

Reviewing studies of companies important. Companies that decreased downtime significantly hold value.

Their experiences can inspire. They can give clear insights. Similar shifts can be made in your organization.

Conclusion

Briefly lowering downtime in production process is vital. It improves efficiency and sustains competitiveness.

Key tactics comprise performing in-depth downtime analyses. Also significant is incorporating preventive maintenance. Investing in training is also an important strategy.

Utilizing automation is a critical factor too. By utilizing these strategies manufacturers can notably reduce downtime.

They can also enhance overall productivity. Each approach has a vital role. This role is in creation of more efficient production environment.