Yarn is the essential raw material for textiles in the textile industry.

Therefore yarn twisting machines are essential for making yarn with appropriate performances such as strength, flexibility, and aesthetics.

Such twisted yarns, thus, can be utilized in developing textiles functionality without compromising on their aesthetic appreciation by consumers.

These machines are important to the industry to sustain good industry standards as the quality of yarn reflects back in the final product.

Textiles are generally irked for big waste production at all levels of procedure.

There are excess raw materials to the nitty-gritty defective apparels at the end of the process.

Most importantly, the fight is to find a proper solution for minimizing this waste without compromising product quality.

The problem is still being resolution from the technical point of view, and yarn twisting machines reduce the likelihood of errors spoiling the twist and, hence, the quality.

How Yarn Twisting Machines Work

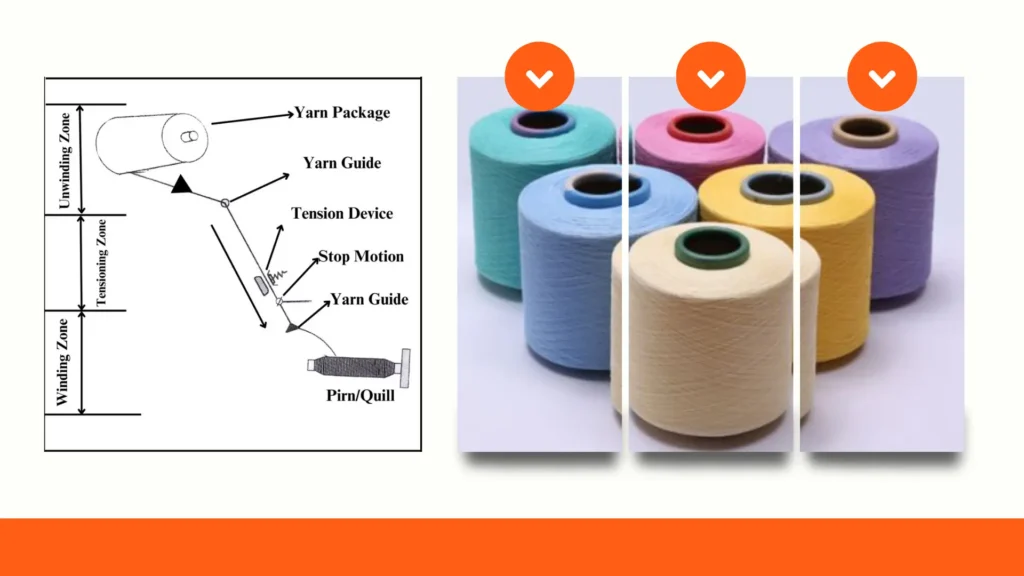

Operation Mechanism of Basic Twisting

Yarn twisting means threading the yarn together to form strands of yarn to give stronger products where multiple yarns are combined.

To do that, the individual fibers are twisted by a rotating spindle under tension.

The outcome is a simple strand of yarn that is less prone to breaking and is considered fit for various textile applications.

Understanding this basic mechanism is fundamental to understanding the great machine value in textile production.

Classifications of Yarn Twisting Machines

There are many different types of textile yarn twisters, and every one of these is specially made for its own use or its own type of yarn material.

Single twist machines are usually employed to twist just one layer of yarn.

On the contrary, double-twist machines have two separate strands that can be twisted together to form an even stronger unit.

Another type, air-jet twisting, makes use of air pressure to twist fibers and seems to be highly advantageous owing to its speed and efficiency.

Learning the differences in these machines is truly important in helping manufacturers identify which machine fulfills the production purposes.

Core Technologies and Features

These are modern yarn twisting machines fitted with computerized controls, automatic tension adjustments, and real-time monitoring systems.

Sure enough, they take operational efficiency to another level because they ensure maximum control of twisting process by eliminating human error and maintaining improved quality of end products.

Besides, many of today’s machines come with easy-maintenance features and an accessible user interface on various skill levels of operator.

And More:

Role of Yarn Twisting Machines in Sustainable Textile Manufacturing

Benefits of Using Yarn Twisting Machines

Several Changes in Quality of Yarn

The foremost advantage of using yarn twisting machines is that it brings about a difference in the quality of yarn produced.

For instance, yam that is twisted is generally found to be stronger and more uniform which plays an important role in producing textiles of high performance.

Improvement in yarn quality is an essential condition to be fulfilled both from the standpoint of meeting consumer demand and also in ensuring the durability of culmination products, with not much risk of returns and dissatisfactions.

Production Efficiency Enhancement

Yarn twisting machines have provided great efficiency gains in production and even made possible some tasks that were once laborious.

Automation has done away entirely with the former time and labor spent on task elongation.

This produced higher output rate, shortened production span, and gave manufacturers much leeway into the rising demands of the markets.

Improved efficiency has increased productivity and at the same time enhanced the allocation of resources within the manufacturing process.

Cost Efficiency

Yarn twisting machines would make the long-term investments of a manufacturer pay well in terms of savings.

The cost in waste would be lowered. Added efficiency would allow a manufacturer to reduce its costs further, overall producing more profit.

The initial investment in these modern machines pays off generally in savings through raw materials, labor costs, and reducing defect rates, thereby making them a wise choice for any textile producer.

And More:

Optimizing Production Processes with Advanced Yarn Twisting Machines

Through Yarn Twisting

Minimize Raw Material Wastes

Apart from the process of minimizing raw materials waste, twisting machines play a prominent role in ensuring optimal yarn waste.

At the same time, they control and perfom the twisting operations, which ensures that every strand of yarn fed into the machine is used and saves on raw materials while resulting in a more sustainable production process.

Reduced Defects and Rework

Defective yarn requires a large quantity of embroidery for rework, making it time consuming and expensive.

The accuracy given by yarn twisting machines avoids possible defects in manufactured products, making the quality standards of production with reduced defects possible.

This results in the conservation of resources and customer benefits, as ultimate high-quality products reduce complaints and returns.

Energy Efficient

Most of modern yarn twisting machines are designed on energy efficient principles.

The twisting process minimizes the amount of energy consumed in the working arena when compared to the counterparts of older models or manual application.

Thus, operational costs are lowered while the effect of the carbon footprint is minimized as per the trend on sustainable manufacturing practices.

Environmental Impact of Yarn Twisting Machines

Sustainable Practices in Textile Production

The textile industry is more and more awake towards the environment and adaption in its usage as yarn twisting machine can definitely enhance sustainability.

Within these machines, waste can be cut down as well as operational saving, both of which underscore the possible future for sustainable manufacture of the textile industry.

It naturally poses an important environmental contribution besides that, which is highly appealing to future consumers concerned with eco-friendly products.

Contribution Towards Eco Friendly Manufacturing

Manufacturers engage into using yarn twisting machines so as to produce textiles that can be used sustainably.

Less waste created, less overall environmental footprint of textile production through resource optimization.

With all these, and as people get more eco-conscious, the manufacturers with an ear on the ground or listening to customers not wanting to be compared with the rest in the world, try to distinguish themselves by offering eco-friendly options.

Compliance with Environmental Laws

Governments are increasingly laying different stringent environmental regulations about which manufacturers will have to dance to remain compliant, and yarn twisting machines that enhance efficiency and reduce waste will be a synonym for profitable manufacturers, helping companies compete with public regulations.

Similarly, investment in high technology that favorably corresponded to environment standards makes manufacturers not only able but well-known carriers in a competitive market.

Choosing the Right Yarn Twisting Machine

Factors to Take Into Account

When selecting yarn twisting machine has to consider many factors such as production capacity, type of yarn to twist, and their budget.

These things, when understood, will ensure that the machine that was selected was in tandem with operational needs that can basically bring about efficiency and quality.

Comparing Different Models

There is a wide range of models in the market for yarn twisting machines, all designed with different but unique specifications.

All the factors of performance, efficiency, and cost should always be compared for the manufactures so that they can choose the suitable one for their production needs.

A deep analysis will tell which machines have the best return on an investment.

Making a Smart Decision

The purchase of yarn twisting machines is a heavy investment for manufacturers so that when it comes time to decide, the manufacturers do not shy away from researching quite a lot, seeking expert advice, and considering long-term operational business intentions before making such a purchase decision.

A well-informed choice is always a guarantee to successful integration and optimized production processes.

Conclusion

Yarn twisting machines help to save wastage in the industry of textiles.

Conveying the yarn quality, enhancing production, and going pertinent to sustainability, their importance must be well understood by anyone and everyone associated with the textile industry—from manufacturers to consumers.

Machines of yarn twisting are some of the most modern and automated machines that improve productivity for process manufacturers by increasing benefits in one area-aiding the cause of environmental sustainability.

Alongside, as the industry grows, these machines will stand apart as qualitatively efficient and responsible facilitators in production.

Now is the time for manufactures that are searching for improvement in production and reduction of wastage to think about yarn twisting machines.

By now investing in the future of textile production, organizations would boost their competitiveness in the industry and contribution to a greener industry.