A yarn twisting machine is an important machine used in the industry where yarn is produced because they are designed to twist together individual fibers or strands to produce yarn.

It has proved to be an important operation, thereby making the contribution under significant enhancement in the strength and texture of the yarn for applications in different lines, such as fashion textiles and industry uses.

With advanced technology of twisting yarn, manufacturers can improve the reliability and style of their products according to the increasing demands of consumers.

Such new features, like automated control, real-time monitoring, and energy efficiency, have made it possible for manufacturers to produce high-quality yarn faster with a smaller amount of waste.

Therefore, it is imperative to understand these technologies to improve production processes for the best competitive position in the ever-changing textile market.

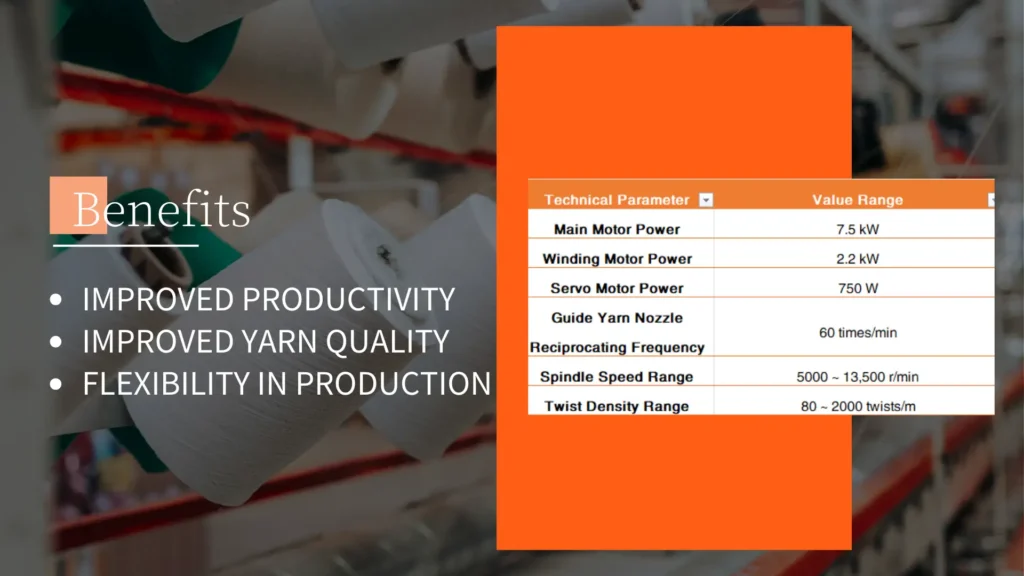

Benefits of Advanced Yarn Twisting Machines

Improved Productivity

One of the main advantages offered by advanced yarn twisting machines is that they work at much higher speeds than machines of previous generations.

Ultimately reduced lead times for the production of yarn can result in improved overall productivity.

Hence, enhanced efficiency assures that organizations will not need to compromise their promise time or rush to respond to market needs to gain a competitive advantage.

Improved Yarn Quality

Modern twisting machines are characterized by highly sophisticated command mechanisms that control twisting tension and tension uniformity throughout the yarn production process.

All this results in a yarn of greater quality which not infrequently surpasses industrial standards.

They are such important components in the manufacture of a product destined to be a household name that such qualities will have a direct bearing on performance and look of the finished textile artifacts.

Flexibility in Production

Advanced twisting machines open new horizons of versatility.

They lend themselves excellently to the manufacture of almost any kind of yarn, make, or style that a manufacturer may dream.

Such a facility will always keep pace with market trends as well as changing consumer preferences.

The consumer putting premium price tags on extremely fine and delicate yarns imported from Europe for fashion, or the customer requiring very strong yarn for heavy-duty industrial applications-the new machines will mean that manufacturers can erect houses made of indoor specimens.

Also Read:

Role of Yarn Twisting Machines in Sustainable Textile Manufacturing

Technological Features to Look For

Automated Control Systems

While choosing the yarn twisting machine, look for those automated kinds of twisting machines.

These type systems monitor twisting parameters and can also adjust them in real-time, which not only minimizes human error but also ensures optimal production conditions.

Thus, it increases consistency and reduces operator intervention, allowing them to focus on the strategic aspects of the task.

Energy Efficiency

It is true that energy-efficient machines have become increasingly important in the textile industry, not only for costs but also because of environmental sustainability.

Modern-day yarn twisting machines come with advanced technologies that consume significantly less power, effectively reducing the operating costs and minimizing its carbon footprint.

Indeed, energy-efficient options are ways of making manufacturers participate in a sustainable future while reaping benefits in terms of profits.

Easy-to-Use Interfaces

Most contemporary machines come with simple user interfaces that make their operation easy for the staff, thus reducing training time.

Such machines are user-friendly, enabling operators to learn the usage of a machine in record time, which would provide better productivity and nearly zero mistakes.

Added to the list is how beneficial this would be in a fast-moving environment where time is glamour.

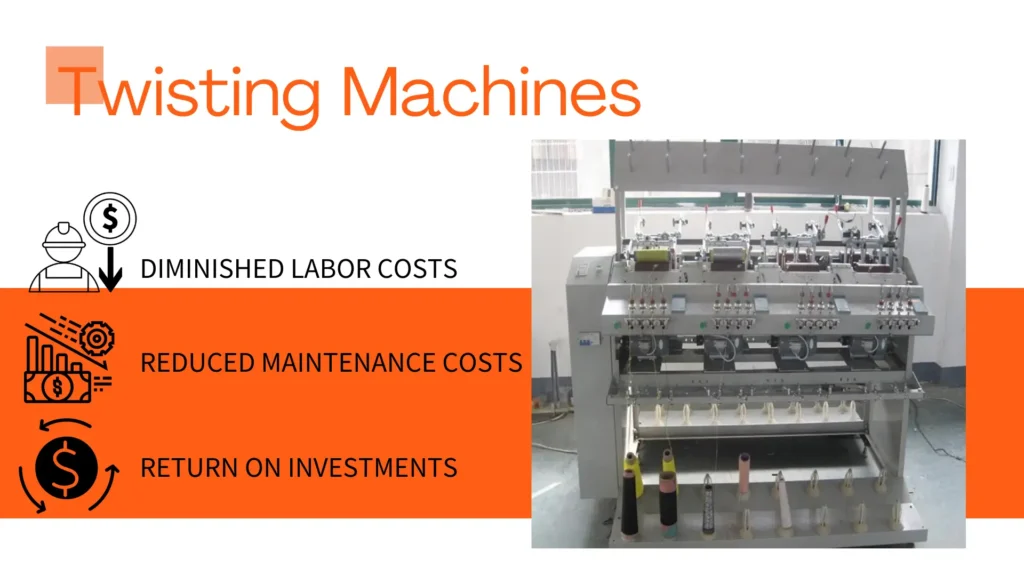

Cost-Effectiveness of Advanced Machines

Diminished Labor Costs

The most prominent benefit of automated yarn twisting machines is reduced labor costs.

Fewer operators are required to run the machine, thus running a more optimized workforce efficiently.

Reduced Maintenance Costs

Most modern day yarn twisting machines are designed for rugged conditions, and thus lower maintenance costs accrue in the long run.

This is more due to fewer breakdowns as well as lesser frequencies of service that bring to manufacturers considerable savings.

This reliability does not only help in reducing the operational disturbances but also provides a more predictable production schedule.

Return on Investments

Ultimately, the capital expenditure should super pay off because modernization of yarn twisting machines brings an excellent shot return by achieving higher productivity with lower costs.

Most new manufacturers will find it easy to recover their investment quickly through a more efficient operational performance with even better quality products.

Assessment of the anticipated returns will enable any organization to consider replacement of old equipment.

Enhancing Sustainability in Production

Eco-Friendly Gears

Many progressive yarn twisting machines work by harmonizing with eco friendly materials as they support the consumersity of the textile towards sustainability.

Hence, sometimes manufacturers could produce such yarns from organic or recycled fibers so that they would be acceptable to eco-friendly consumers who want to fasten and continue with the current trend of the industry.

Waste Minimization

Basically, twisting can be optimized so that massive waste cuts are made for the plant.

Equipped with progressive features, machines offer excellent arrangements in minimizing scrap and recycling waste materials, thus enhancing efficiency.

Finally, waste minimization has been evidenced to lower production costs of manufacturers and contribute to sustainability in the textile industry.

Compliance with Regulations

New machines would help manufacturers in complying with environmental regulations.

Most modern machines are designed specifically with sustainability in mind; hence, all operations are supposed to fulfill the industry standards without quality compromise.

Also, these regulations are very good for the environment and help in building a company’s reputation.

And More:

Five Key Points for Production Process Optimization

Competitive Advantage in the Market

In Meeting the Markets

Advanced twisting machines will give textile manufacturers a significant advantage over their competitors as market demands continue to escalate.

For them, speed will be everything: having the capability of producing specialty yarns quickly offers a manufacturer the opportunity to respond effectively to market demand.

Consumer behaviour shifts; technology in place means that manufacturers can change and adapt their offerings to their extents.

Innovation and Flexibility

Ever-the-daring manufacturer steps ahead of the time about developing technology.

In fact, it may have adopted the latest high technology yarn twisting machines to turn its production activity an increment toward being better able to innovate new products that suit the emerging trends.

It is this adaptability that can let an enterprise survive change in an ever-accelerating market.

Strengthening Brand Reputation

With using such machines, the full heft behind producing world-class yarn will work wonders in adding to the manufacturer’s reputation.

The customer probably will re-evaluate the subject to him and then put his recommendation for the brand in front of everyone else.

A strong reputation for quality and reliability not only prevalence among the public but also attracts new clients to contribute to very long-term growth.

Training and Support for Operators

Requirement of Adequate Training

The operators must also be well-trained in handling advanced machines, which brings about maximization of productivity and minimization of errors.

The comprehensiveness of a training program can help make a great difference in production efficiency by helping staff develop confidence in using machines.

Continued Support from Manufacturers

Excellent machinery suppliers provide continued support and resources for operators in the forms of training programs, manuals, and customer services to help deal with issues arising from lacking production.

Such support serves well in ensuring the smooth operation and optimal performance of the machine.

Building a Skilled Workforce

Staff training is effective in developing machine operating skills as well as overall human skills.

With knowledge, a team is likely to face challenges more effectively, optimize production processes, and implement new technologies.

Building a skilled workforce is thus an investment that will pay off later for increased efficiency and innovation.

Conclusion

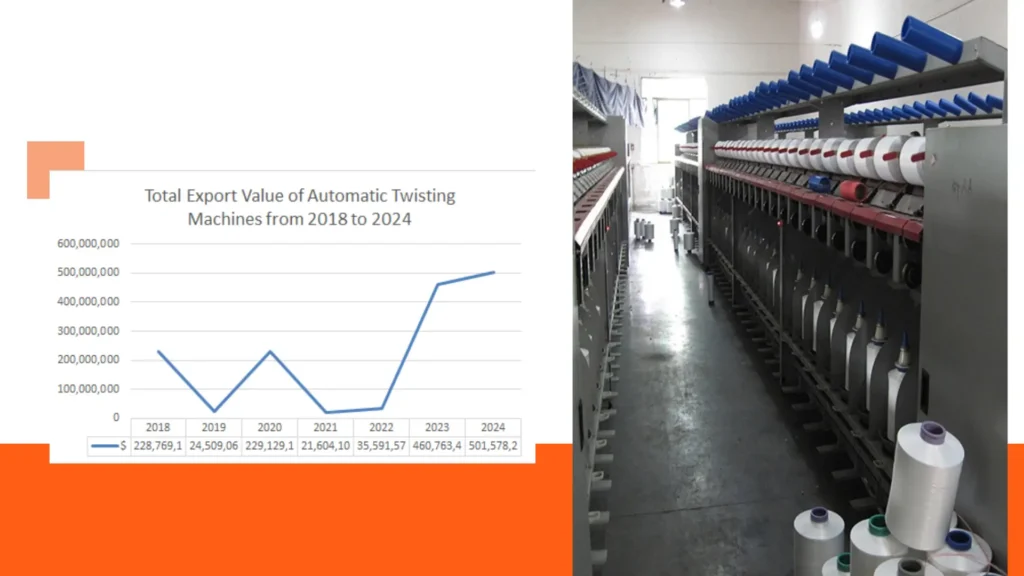

Continuous change in the technology will turn the spotlight on yarn twisting machines in a few years.

Innovations revolving around automated industry operations, sustainability enhancement, and efficient production will keep the industry a consistent hotbed for.

Manufacturers should consider investing in advanced yarn twisting machines to improve their production processes.

This is how big they will get in terms of improving yield, cost efficiency and product quality. It is time to invest in the future of textile production.

Integrating and maximizing advanced yarn twisting machines into production operations moves the industry beyond operational efficiency to strategic thrust in realizing a future of greater efficiency, sustainability, and competitiveness.

Those who adopt it have positioned themselves for success while continuing to delight their consumers through handling meaningful sustainability along the way.