Winding machines are key tools in multiple industries. These industries span from electronics to textiles.

These machines effectively wind materials into coils or spools. They play a critical role in the manufacturing process. Understanding specifications of these machines is crucial.

It is vital for businesses that want to invest in reliable and highly efficient machines. This guide is designed to assist potential buyers. It aids in navigating key specifications needed to make well-informed decisions.

These decisions are especially important while considering the purchase of a winding machine.

Learn More:

Essential Insights into Winding Machine SpecificationsYour Ultimate Buying Guide

What is a Winding Machine?

Definition

A winding machine is specifically designed for winding materials. These materials include wire cable or yarn.

The intention is to create organized coils or spools. The process is integral to many production lines. These lines invariably require precise winding for peak performance and product quality.

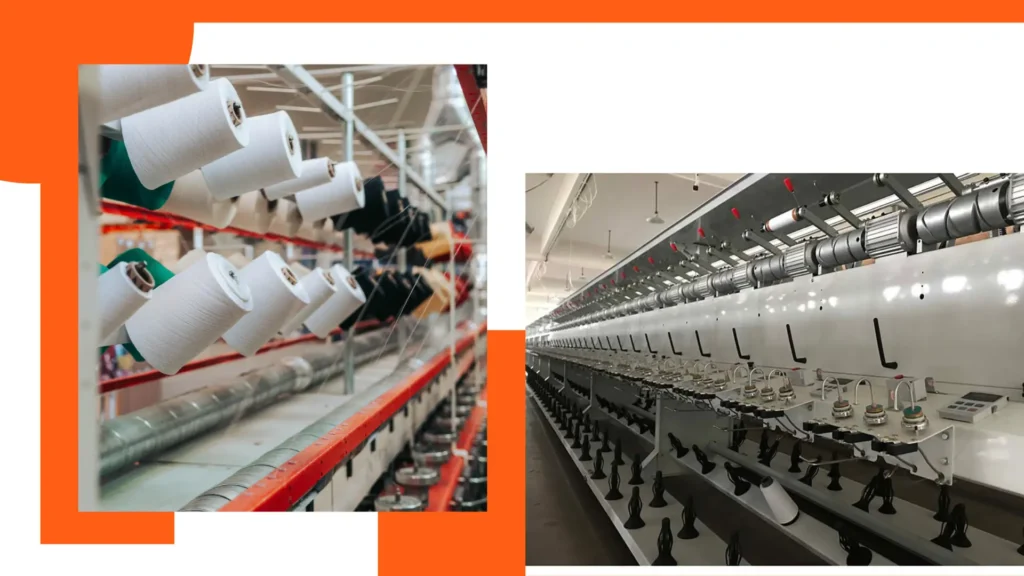

Applications

Winding machines have found applications across sectors. In electronics industry they find use for producing components like transformers and inductors. In textiles they are handy for winding yarns for fabric production.

The versatility of winding machines make them indispensable in manufacturing – modern manufacturing.

Importance

Importance of winding machines can’t be overstated. They enhance efficiency in production.

They ensure materials are wound correctly and uniformly. Uniformity not only improves quality of finished product.

It also reduces waste which contributes to more sustainable manufacturing practices.

Key Specifications to Consider

Winding Capacity

Material Compatibility

Various winding devices can process a variety of materials. These range from delicate wires to robust cables.

It’s critical to pick a machine. It should cater for materials you plan to use. Optimal performance is ensured this way.

Coil Size

Producing coils is crucial. It is also important to get the dimensions correct.

Both the diameter and length of coils are needed for applications. This directly affects your production capabilities.

Speed and Efficiency

Production Speed

Winding speed is a critical factor. It is typically measured in meters per minute. Higher speed capabilities are beneficial.

They significantly boost productivity.

More units can be constructed in less time. This happens when productivity is enhanced.

Energy Consumption

Energy costs are on the rise. Picking a winding machine is important. This machine needs to offer energy-efficient operation. Machines made for lower energy consumption are of help.

They help to reduce total operational costs. They too, contribute to sustainability efforts.

Control Systems

User Interface

Control panel that’s user-friendly can greatly simplify. It simplifies operation of winding machines.

This is especially true for operators with varying levels of expertise. Intuitive controls are present. They reduce the learning curve. They improve efficiency.

Automation Features

Modern winding machines often have advanced automation features. They include automatic tension control and programmable settings.

These features actually enhance precision. They also lower risk of manual errors. The result is higher quality output.

Durability and Maintenance

Build Quality

Materials and construction quality impacts winding machines. This affects their endurance and reliability.

Machines made from robust materials can handle the stress of uninterrupted operation. As a result, this lowers breakdown chances.

Maintenance Requirements

Deliberate machinery designed for simple maintenance. Machinery necessitates minimal downtime for servicing.

It also has readily available replacement parts. Both these factors uphold productivity.

Types of Winding Machines

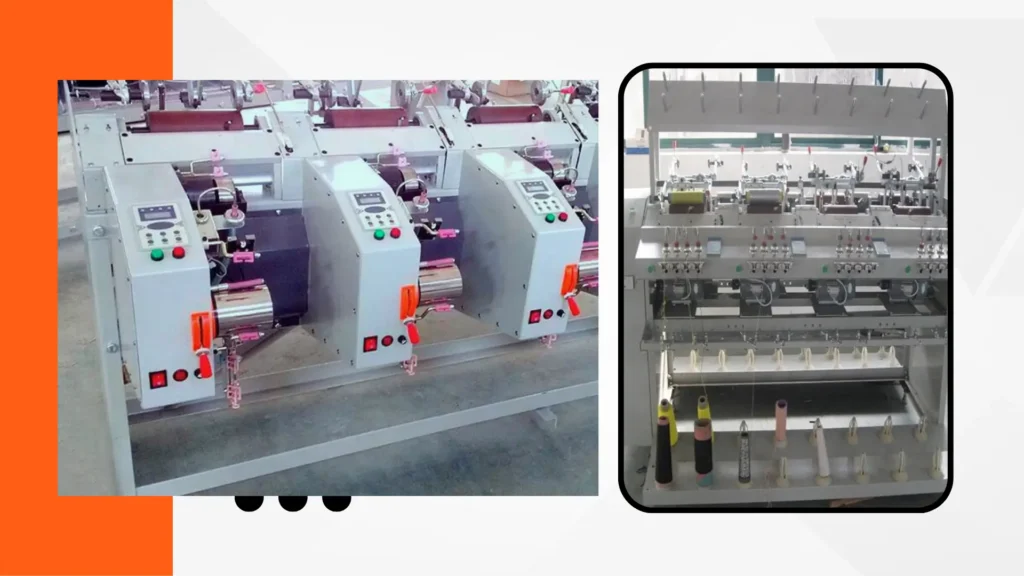

Manual vs. Automatic

Manual Machines

Oftentimes machines necessitate operator involvement for winding processes. They suit small-scale production well.

Or they are beneficial for specialized tasks where precision is crucial. However they aren’t as effective as automatic models for larger operations.

Automatic Machines

Attributes of winding are boosted by automatic winding machines. Higher efficiency results.

Furthermore they can function independently. Minimal human intervention is situational, making the machines ideal for large-scale production.

Specialty Winding Machines

Transformers Winding Machine

These machines are made specifically. Their purpose is for winding coils. These coils are for transformers.

The machines are often tailored for the special needs of transformer construction.

Textile Winding Machines

Machines designed for winding are what we consider now. These machines are used for winding yarn.

Additionally they are used for fabric. Their main goal is to ensure that textiles are wound in a uniform manner.

This uniformity is critical for next steps. It is also critical for quality control.

Custom Winding Solutions

Tailored Designs

Certain manufacturers propose personalized winding machines. The intent is to align with detailed production demands.

Personalized solutions can truly optimize operation. They are aimed at unique circumstances.

Adaptability

Machines comfortable with quick material or coil changes offer flexibility. They cater to market demands speedily.

Benefits of Investing in Quality Winding Machines

And More:

Unlocking Efficiency: The Benefits of Investing in Quality Winding Machines

Enhanced Production Quality

Uniformity

Winding apparatus of superior quality, provide consistent results. This ensures every coil winds uniformly.

This regularity is vital. It is needed to preserve final product’s quality.

Less Waste

Accurate winding methods are used to reduce waste of material. This reduction in waste is beneficial.

It saves costs and also leads to more eco-friendly practices in manufacturing.

Increased Productivity

Faster Operation

Machines which have high speeds can boost overall production rates. This helps businesses to efficiently meet demands.

Less Downtime

Durable machines require less frequent repairs.

This contributes to a stable production environment. It reduces the chance of unexpected downtime.

Cost-Effectiveness

Savings in Long Term

Investing in quality winding machines can result in savings over a long period. This is due to reduced maintenance needs and the machines’ energy efficiency.

ROI is Higher

Efficient machines heighten productivity. The quality of products also improves. This leads to better returns on investment.

This makes them a prudent choice for manufacturers.

Choosing the Right Winding Machine

Learn More:

Choosing the Right Winding Machine: A Comprehensive Guide for Buyers

Assessing Your Needs

Production Volume

Determine volume of material needed for winding. Base this on production goals. This assessment will help in selecting machine with suitable capacity.

Material Types

Identify specific materials you’ll work with. Different machines have varying capabilities in terms of material handling.

Researching Options

Comparing Brands

Look at different brands. Check their specifications. Find machines meeting your needs. Each brand might offer unique features.

They can also offer benefits that could be advantageous.

Reading Reviews

Feedback from customers offers valuable insights. It speaks of how winding machines perform.

It speaks of their reliability. It assists you in making a more informed choice.

Consulting Experts

Industry Specialists

You should seek recommendations from professionals. They need to have experience in winding machines.

Their expertise is invaluable. They can aid you in navigating complex specifications. They can assist you in making the proper choice.

Supplier Recommendations

Dependable suppliers can provide suitable suggestions. They base their recommendations on your production requirements.

They consider your budget. This process ensures that you discover the best fit.

Maintenance Tips for Winding Machines

And More:

Essential Maintenance Tips for Winding Machines: Keep Your Equipment Running Smoothly

Regular Inspections

Scheduled Maintenance

Put in place a regular check-up schedule. This will let you catch possible problems early. Regular checks can halt breakdowns. They can be expensive.

Check Moving Parts

Look often at belts gears and other moving pieces. These show signs of wear and tear very soon.

Being proactive in this way will assist in keeping best possible performance.

Cleaning Procedures

Dust and Debris

Clean the machine regularly. It is crucial to avoid malfunctions. Regular cleaning removes dust and debris. These can interfere with the machine’s functioning.

Lubrication

Make sure to apply them to moving parts. This will help with smooth functioning.

Lubrication makes sure less friction is in action. This also prolongs the machine’s life.

Replacement Parts

Stock Essential Items

Maintain commonly required replacement pieces nearby. This minimizes downtime in the event of a repair.

Quick access to parts can dramatically enhance operational effectiveness.

Relate to Suppliers

Need a good rapport with suppliers. They guarantee swift access to necessary part. Dependable suppliers offer backing and advice. This helps with upkeep of equipment.

Common Challenges and Solutions

Operational Issues

Tension Control Problems

Experience issues with tension control? Ensure proper calibration of machine. Regular adjustments can maintain consistent winding.

Speed Variations

Fluctuations in speed can signify mechanical problems. Regular upkeep and inspections can pinpoint and fix these issues.

Material Handling

Material Breakage

To prevent material breakage employ proper tension settings. Refer to the material’s characteristics. Make necessary adjustments to improve winding process.

Coil Misalignment

Consistent adjustments and calibrations can help. They maintain alignment during winding process. This ensures high-quality output.

Technical Support

Training

Comprehensive training should be provided. This is for operators. It enhances their understanding machine operations.

Well-trained staff can operate machines more efficiently. They can also operate them safely.

Troubleshooting Guides

Maintain troubleshooting resources. Make them easy to follow. These resources help operators address issues quickly. This can minimize downtime. It also improves productivity.

Future Trends in Winding Technology

Automation and Smart Technology

IoT Integration

Machines of the future could incorporate Internet of Things (IoT) functions. This would allow for remote monitoring and control.

This technology can indeed improve operational efficiency. Also it could improve maintenance.

AI Optimization

Artificial intelligence (AI) might be used for optimizing winding processes. They could do this by predicting maintenance needs. Moreover, it might improve overall performance.

Sustainability Focus

Eco-Friendly Materials

A trend is growing. It is towards the use of sustainable materials. Particularly in machine construction and operation.

Sustainability is focus of this. It is in line with global efforts. These efforts aim to reduce environmental impact.

Energy-Efficient Designs

There are innovations. These are aimed at reducing energy consumption. They are becoming more popular.

They help manufacturers to lower their carbon footprint. They also help to decrease operational costs.

Customization Options

Modular Designs

Machines are developed with increasing ease of customization. They start to gain more popularity. This modular design is allowing businesses to adapt their equipment. They can do this to meet the changing production needs.

User-Friendly Software

Sophisticated software for machine operation is available. This software will enhance usability. It will be easier for operators to manage complex winding tasks.

Conclusion

Comprehending specifications of winding machines is crucial. It helps in making informed purchase choices.

By weighing factors such as winding capacity and speed businesses can select suitable machines. Also they can consider control systems and durability. These machines are selected to align with production needs.

Investing in appropriate winding machine enhances production quality. It can also boost efficiency. This makes it a crucial asset in manufacturing operation.

Are you ready to explore the options for winding machines? Our team is here to help. We will help you find perfect solution for winding needs!