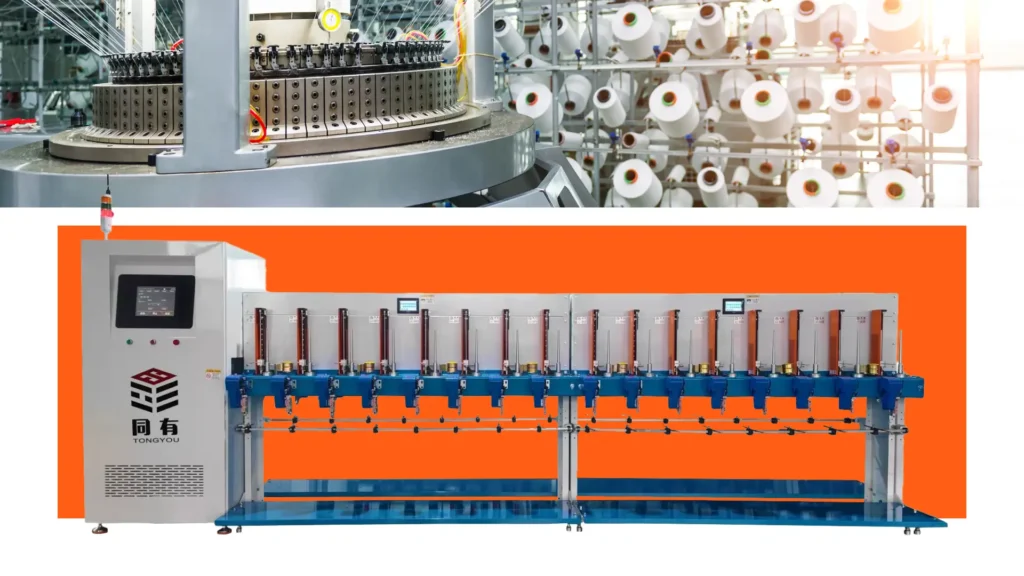

Automatic winding machine is a type of industrial equipment. It is built to wind materials into coils or spools. Materials like wire, yarn or film. The machine works without the need for constant user input.

This equipment holds significance in a variety of manufacturing processes. They deliver efficiency and preciseness.

Winding process is automated with this machine. This leads to reduction in labor costs and amelioration in product quality.

Automatic winding machines are indispensable. They are for businesses aiming for high productivity.

Understanding price of these machines is vital. Companies seeking to invest in new equipment must consider it. The price not only influences initial investment. It impacts the overall return on investment too.

Factors Influencing Automatic Winding Machine Prices

Machine Features and Specifications

Price of an automatic winding machine is significantly influenced by its features and specifications.

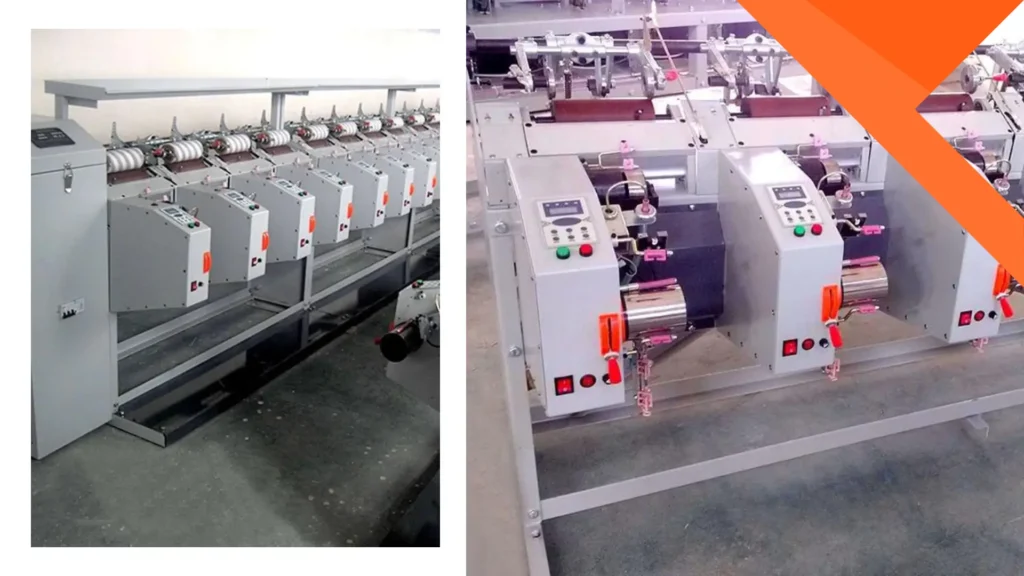

Machines with advanced technology tend to be more expensive. Technology such as programmable settings high-speed capabilities and precision control systems.

Materials they can handle and their overall build quality are important too. These play a role in determining price of machine. Buyers should evaluate features.

Not all features are essential for their specific applications. This can help justify their investment.

Brand Reputation and Reliability

Brand reputation is another critical factor affecting prices. Manufacturers who have a history of making reliable and high-quality machines normally command higher prices.

This is due to their reputation. Consumers are more willing to pay a premium for brands that have a track record of superior customer service, warranty support and product durability.

To invest in reputable brand can result in long-term savings. This is through less downtime and lower maintenance costs.

Market Demand and Supply Dynamics

Prices of automatic winding machines are influenced by market demand supply dynamics. In periods of high demand, prices may surge.

This surge is due to buyer competition. Conversely in saturated market prices drop. These drops are because of many suppliers.

Being informed about market trends helps buyers. It allows them to time their purchases effectively. They can secure better deals.

Price Ranges for Automatic Winding Machines

Entry-Level Machines

Automatic winding machines at entry-level typically cost between $5,000 to $15,000. These machines suit small businesses or startups. These companies need basic winding capabilities.

They don’t need extensive features. They are often manual. Sometimes they are semi-automatic. This makes them affordable. They still provide vital winding functions.

Mid-Range Machines

Mid-range automatic winding machines usually have price tags between $15,000 to $50,000.

These models give a balanced mix of features. At the same time they offer improved efficiency. They are perfect for businesses that are medium-sized and seek dependable performance.

They do not need high production volumes. They often include automation features.

They have quality builds. They provide good investment returns. They are best suited for expanding operations.

High-End Machines

Top-tier self-winding machines cost. They range from $50,000 to $100,000 and above.

These machines pack most recent tech. They offer uber-advanced mechanics. High-speed function is their forte. Also they excel in exact precision.

Perfection is not their only forte however. They are perfect for large manufacturers.

Specialized applications also find them invaluable. These situations often demand very high performance.

Even so, initial investment is hefty. Nevertheless potential to increase production efficiency exists. Lower labor costs could also work to justify such an expense.

Comparing Prices Across Different Brands

Top Brands in Market

Several brands reign supreme within automatic winding machine market. Each touting unique strengths and weaknesses.

Conducting research on these brands offers insights. It offers a window into their distinct offerings. It assists buyers in identifying which brand aligns with their needs. As well as their budget.

Comparing Strategies of Price

For making informed decisions on purchase buyers must use effective price comparison techniques. They need to get quotes from multiple suppliers. Furthermore they should read online reviews.

They also need to use industry forums. This is for gathering opinions from other users. Comparing not only prices but also features and warranty options will lead to better decisions.

Importance of Warranty and Support

When weighing prices it’s crucial to contemplate the warranty and support from manufacturers.

A more extended warranty duration may defend a higher cost. It’s an indicator of the manufacturer’s faith in product.

Besides dependable customer support can expedite resolution of the issues. This minimizes downtime and ensuring operations remains smooth.

Tips for Finding the Best Deals

Seasonal Sales & Discounts

Many buyers find substantial savings with seasonal sales and discounts. Manufacturers and suppliers often offer promotions. These are during specific times throughout the year.

Such times can be holidays or industry trade shows. By keeping an eye on these sales buyers can save a lot of money. The savings can be on automatic winding machines.

Negotiation with Suppliers

Negotiation is valuable. It is a skill when one buys industrial equipment. Buyers shouldn’t hesitate to discuss prices with suppliers. There could be room for discounts.

This is especially true for bulk purchases or returning customers. Building a good relationship with suppliers can lead to better deals in future.

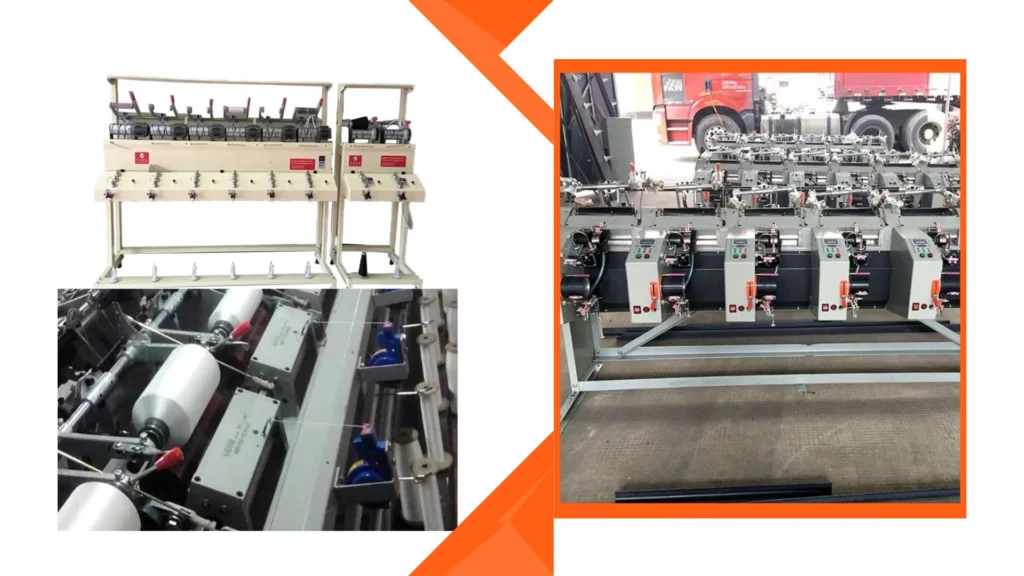

Considering Used or Refurbished Machines

For buyers who are conscious about budget used or refurbished automatic winding machines can be an excellent option.

These machines are often available at a fraction of the cost of new ones. This is while still providing reliable performance. It is crucial though to verify the machine’s condition.

Also ensure it comes with some form of warranty. Or perhaps a service agreement.

And More:

- Essential Factors to Consider When Choosing an Automatic Winding Machine

- A Comprehensive Comparison of Automatic Winding Machines: Efficiency, Accuracy, and Reliability

Understanding Total Cost of Ownership

Initial Purchase Price vs. Long-Term Costs

When examining the cost of automatic winding machine we must consider both the initial purchase price and the long-term costs.

The early investment often involves a significant expense. Yet this is not the only financial consideration. Long term operating costs are part of the equation too.

These machines use electricity. So, we must factor in the energy consumption. Also there is upkeep to think about. Maintenance can be costly. Labor cost is another factor.

A machine could have a higher price at the time of purchase. But over time it might need less maintenance. It may consume less energy. This can save a lot of money. It might work out cheaper over its lifetime.

Buyers need to do a thorough cost analysis. They should take into account projected maintenance schedules.

They should consider potential repairs. It is also important to know the machine’s expected lifespan. Only then can they get a clear understanding of how the purchase will impact their finances.

Resale Value Considerations

Resale value an important aspect of total cost of ownership is often forgotten by buyers.

A variety of factors can affect resale value of automatic winding machine. This includes the reputation of brand, features of machine and its overall condition.

Machines of high quality from brands known for their reputation tend to keep their value. This is in contrast to their lower quality counterparts. It is of utmost importance for operators to maintain the equipment well.

This can be done by following the suggested maintenance schedules. Operators must also keep records of all services performed.

To understand market trends and demand for specific machines can assist sellers. This can help them in making informed decisions. Decisions about timing and pricing of resale.

Financing Options for Automatic Winding Machines

Leasing vs Buying

Consideration of how to get automatic winding machine is common for businesses They often ponder on pros and cons of leasing and outright purchasing.

Leasing might be beneficial. Especially for companies with limited cash flow. Leasing allows them to get equipment without a big upfront payment.

It can also offer flexibility. Businesses can upgrade to newer models more frequently.

On the other hand, purchasing a machine can be a better long-term investment. This is because it builds equity. This process also eliminates ongoing lease payments.

Businesses should evaluate their financial situation and production needs. They should also assess long-term goals. This way they can determine which option aligns best with operational strategy.

Exploring Financing Solutions

Businesses looking to buy automatic winding machines have various financing choices.

Traditional bank loans are an option. Alternatively they can explore equipment financing through specialized lenders.

An even more viable option could be manufacturer financing options. These can be beneficial as they can spread the cost over manageable terms.

Each financing solution has its own set of terms interest rates and eligibility criteria. It’s crucial for buyers to explore these and compare the choices. Businesses should also consider their cash flow projections.

Different financing plans will have varied effects on their overall financial health. It would be wise to consult with a financial advisor.

Such consultation can offer important insights for choosing the best financing strategy. This strategy can lead to a good deal when buying winding machines.

Conclusion

In conclusion understanding is key. Factors that influence automatic winding machine prices are essential for informed purchasing decisions. Buyers should consider features.

They should think about brand reputation and market dynamics. This way they can better assess options. They can also find machines that meet their needs and budget.

Potential buyers should get into research. They are encouraged to compare prices. The comparison should be done across different brands and models. Evaluating all options is time consuming.

However in the end, it can lead to better investment choices. It can also enhance productivity. This is especially true in manufacturing processes.