Cost efficiency is paramount in today’s fierce manufacturing world. Businesses strive to heighten profits.

Yet they also want to decrease operational costs. Importing automatic winding machines from China can be a significant investment.

Therefore understanding how to maximize cost efficiency becomes vital. Strategic sourcing can be used for companies to ensure getting the best value. These are important in these investments.

In past few years, a notable trend has been seen. There is a rise in sourcing machinery from China.

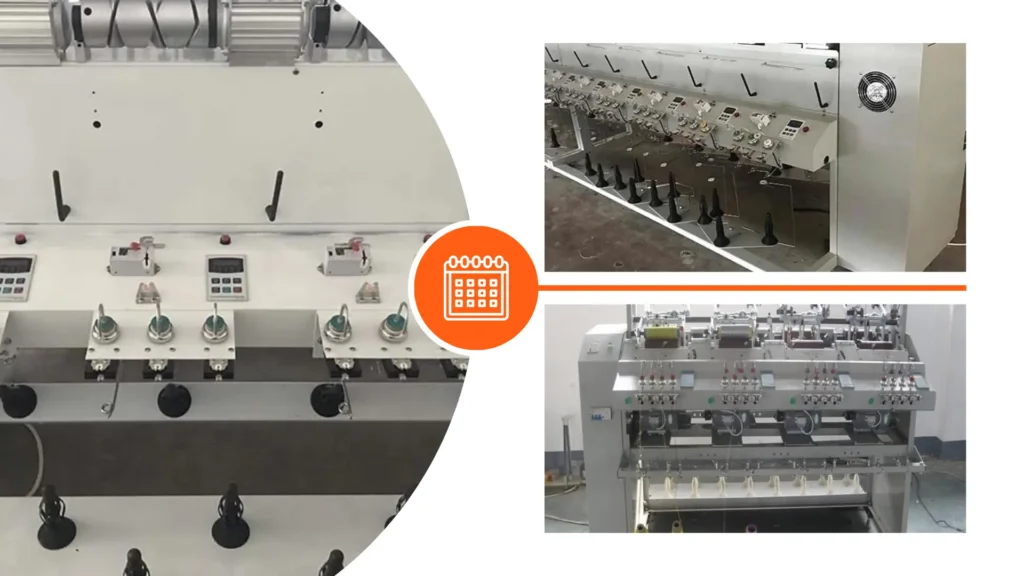

Chinese manufacturers provide many automatic winding machines at competitive prices. This makes it an appealing option for companies worldwide. We will provide a guide on navigating complexities of importing these machines. Here we keep costs in check.

Comparative Cost Analysis: Domestic vs. Import

Breakdown of Costs Associated with Domestic Machines Versus Imported Ones

When assessing the costs of domestic machines against imported ones numerous points come into play.

Domestic machines often bear higher price tags. The reason behind this is escalated production costs. These include labor and material expenses.

Conversely, imported machines from China often see benefits. These benefits are due to lower labor costs and the economy of scale.

Factors Influencing the Price Difference, Such as Labor and Materials

The price difference can be attributed to the lower labor costs in China. It is where manufacturing is often more cost-efficient. Moreover the availability of raw materials is crucial.

Advanced manufacturing technologies in China cannot be discounted. These aspects contribute to the lowered costs of machinery.

Understanding these factors is paramount. It allows businesses to make knowledgeable purchasing decisions.

The Importance of Bulk Buying and Its Benefits

Explanation of Bulk Purchasing and How It Can Lower Unit Costs

Bulk purchasing is obtaining more items. These can be machines or components.

This practice can significantly slash the unit cost. Suppliers often give discounts for large orders.

This helps businesses save money over time. Companies preparing for high production volumes find this strategy beneficial.

Discussion on Storage and Inventory Management Considerations

Bulk buying can result in cost efficiency. However we must remember to take into account storage and inventory management. It is crucial. Companies must confirm that they have ample space.

They also need the right systems in place. This will help manage greater quantities of machinery.

Efficient inventory management can stem from overstock. It also helps in reducing any related costs.

It is about more than just getting a good deal on bulk buys. It’s about making sure these purchases don’t cause headaches down the line.

Leveraging Trade Agreements to Reduce Costs

Overview of Relevant Trade Agreements Between Countries

Various nations possess trade agreements. These pacts can slash tariffs and import charges on machinery.

Agreements of the sort ease trade relations. Consequently significant savings are possible for businesses.

This appears particularly to those that import equipment.

How These Agreements Can Lead to Reduced Tariffs and Import Fees

Businesses can benefit via existing trade agreements. Reduced tariffs are a benefit. This makes imported machines cheaper. It is crucial to research trade agreements.

Consult with trade experts. This will maximize advantages when importing from China.

Reducing Maintenance and Operational Costs

Tips for Selecting Machines That Require Less Maintenance

With automatic winding machines choose models that have a reputation for high reliability.

Look for low maintenance requirements. Consider things like sturdy construction and high-quality components.

These features can endure repeated use. They also help to avoid constant repairs.

Importance of Energy Efficiency in Reducing Operational Costs

Machines that use energy efficiently can lower utility costs. Essentially they lead to a more sustainable operation.

Machines that incorporate energy-saving technologies are wise investments. They can generate substantial cost savings over time. They’re particularly suitable for any business.

Warranty and After-Sales Support for Chinese Machinery

Importance of Understanding Warranty Terms When Importing

Understanding the warranty terms is crucial. It’s important during an import. Warranties are key as they safeguard your investment. It’s a must to grasp what the supplier offers in terms of warranty.

This includes understanding the duration of coverage and what comes under it. Such knowledge helps in reducing the risks associated with potential defects. It also helps in the case of malfunctions.

Evaluating the Quality of After-Sales Support from Suppliers

Assessing supplier’s after-sales support quality is quite significant too. A reliable supplier should provide extensive support. This includes technical help, availability of spare parts and different service options.

Reviews and testimonials from customers that are positive can provide insights. They reflect a supplier’s quality of after-sales service.

Choosing the Right Supplier

Criteria for Selecting Reliable Suppliers in China

Resource management can also reduce costs with efficient use of resources. Costs are minimized. Several challenges exist for cost control in logistics. These challenges include unpredictable fuel costs.

They also include rigid delivery schedules. But with right strategies cost control in logistics is achievable.

Importance of Supplier Reputation and Customer Reviews

Shipping expenses vary significantly from one base to another. This is dependent on the selected plan.

The methods involve sea, air, rail. For larger deliveries sea is usually the most economic method. This occurs due to air freight that may be more costly but quicker.

Understanding Shipping and Logistics Costs

First comprehend the costs of shipping. This includes variables such as freight charges packaging and delivery. Additional expenses might be incurred too. These could be warehouse handling fees or insurance coverage.

Knowing these costs is vital. It will help in estimating overall budget of a project. Furthermore, it could help avoid unanticipated expenditures.

Breakdown of Shipping Options and Their Costs

Shipping costs have variations based on chosen method. For instance sea freight air freight or rail transport. Sea freight is usually most cost-effective for large shipments.

Air freight, by contrast, is often more expensive. However it offers quicker delivery.

Understanding these options is crucial. It aids businesses in selecting the most appropriate shipping method.

Tips for Optimizing Logistics to Save Money

Optimizing logistics costs is possible. Look into consolidating shipments. Negotiate rates with logistics providers.

Plan shipments strategically. Efficient logistics management can generate savings. It will also enhance cost efficiency of importing machinery.

Regulatory Compliance and Import Duties

Overview of Necessary Regulations for Importing Machinery

It’s critically important to comply with regulations. This ensures a smooth process during the import. One should be familiar with regulations.

The importation of machinery in your country is governed by these regulations. Safety standards and documentation requirements must be specifically mentioned.

How to Navigate Import Duties to Avoid Unexpected Costs

Understanding duties of import is crucial. It is important when dealing with machinery imports.

It can help in preventing surprise expenses.

Do some research. You need to know specific import duties related to your machinery.

Work together with customs brokers.

This ensures compliance. It also ensures accuracy in duty calculations.

Conclusion

Maximizing cost efficiency is key.

Take it into consideration when importing automatic winding machines. China often serves as the primary source.

It involves careful planning. Informed decision-making is essential. Cost comparisons provide understanding.

Bulk buying is a benefit. It can cut costs. Supplier evaluation also plays a role. Businesses can enhance profitability. It’s a great opportunity.

During your sourcing journey, remember to conduct thorough research. It’s vital. Strategic planning is equally crucial.

These are key to success. Guide insights should be followed. They will assist you. You’ll successfully navigate import complexities.