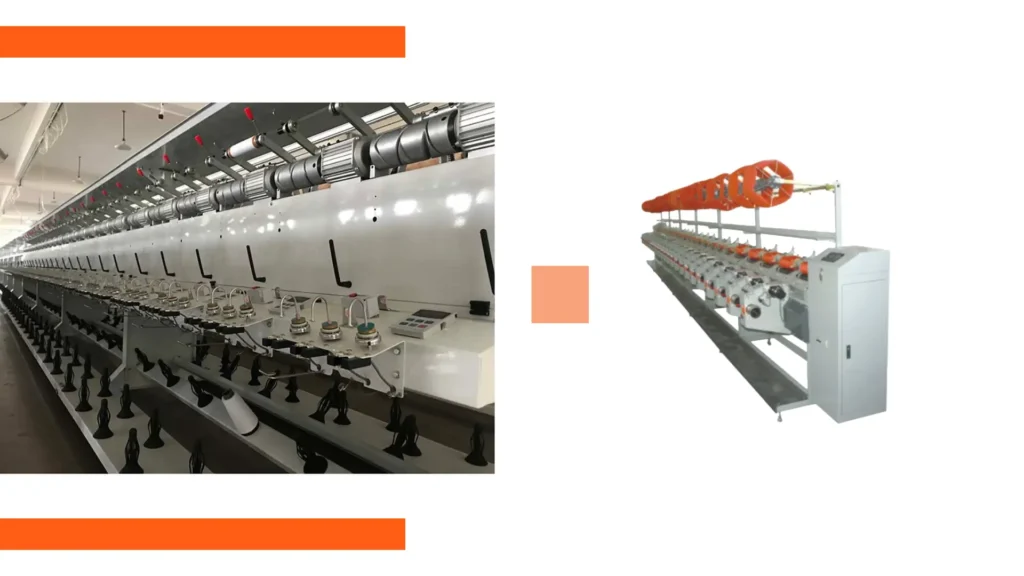

Yarn twisting machines are prominent in the textile world production, being the heart of high-quality yarns from which various different textile products may eventually be formed.

They expertly twist fibers together to form the yarn from which it will be woven or knitted into fabric.

Like any other complex machinery, they require periodic maintenance and running to use them at their peak efficiency and, therefore, achieve a better quality yarn.

This article shares some simple maintenance tips that can keep your yarn twisting machines working at their optimum condition, hence prolonging their lifespan and enhancing your production quality.

Importance of Regular Maintenance

Preventive Care

Like daily screening for our health, preventive maintenance must be done to machines regularly, just as frequent checking of parts and services.

Having preventive care means that an inspection and maintenance need to be performed periodically on equipment or machines to catch any possible problem before it turns serious.

Not only does preventive maintenance minimize costly repairs but it also helps avoid the unforeseen breakdowns that can affect production schedules.

You can thus ensure that your machines are operating at maximum performance and efficiently.

Cost efficiency

Maintenance should always be undertaken regularly. Machines with regular care tend to eliminate or minimize major failures that usually occur and trigger expensive repairs and long idle time.

Using your machines efficiently would consume less energy and generate fewer defects regarding productivity, eventually profits, and overall cost savings.

Maintenance can be considered a kind of investment that pays back profits by accessing increased operational efficiency.

Quality Assurance

Good quality output is a must in the competitive textile market.

Properly maintained yarn twisting machines can produce yarns of good quality consistently, which are essential for customer satisfaction and the brand’s name.

When our machines are in top-sounding condition, your yarn is less likely to suffer from defects or inconsistencies, thus enabling it to deliver the reliability expected by your customers.

Components of a Yarn Twisting Machine

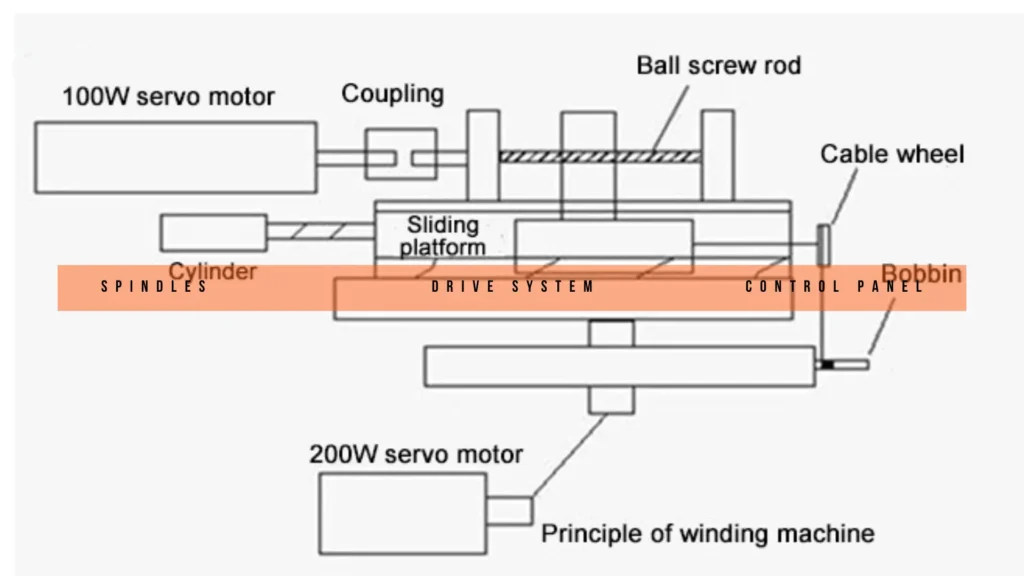

Spindles

Spindles are the parts or components in a yarn twisting machine that actually twist fibers into yarns.

Their performance directly relates to the quality and consistency of yarn formed in a yarn-twisting machine.

Understanding how spindles work and knowing their maintenance requirements becomes important for troubleshooting as well as assured performance.

A normal check-up on the condition of spindles may prevent defects such as uneven twisting and yarn breakage.

Drive System

The part of the drive system includes motors, belts, and gears, all working to power the machine and make it move.

Any malfunction in this system can lead to a significant drop in performance.

Inspections carried out regularly can easily identify those potential symptoms like worn belts or misaligned gears while they are still harmless and have not made the machine fail.

The efficient working of this system is vital to maintaining the total efficiency of the machine.

Control Panel

This is where operators adjust machine settings and check observed performance.

Therefore, it will be ideal for every operator to be familiar with handling the control panel.

Moreover, in maintaining optimal performance, it is advantageous for operators to carry out periodical calibrations and updates on machine performance settings as reflected on the control panel.

Common Issues Faced

Wear and Tear

Machines are consummately prone to wear and tear as they age and undergo major issues as a result of constantly running.

It results in the deterioration of their efficiency and quality of productions.

Thus, one must know very early wear symptoms such as strange noise or vibration to arrest them timely.

The regular inspections can identify such faulty parts on time before they generate major problems and keep machines running smoothly.

Obstruction

They can get dust, lint, and other deposits with time at various parts of the machine and make blockage in the twisting process.

This requires routine cleaning to ensure that there is no accumulation.

A well-organized routine cleaning should have been a recommendation to ensure effective airflow and blockage build-up, which would hinder smooth performance of machine operations and quality of yarn.

Misalignment

Due to the vibrations or handing inappropriately, parts of the machine go out of alignment.

Ideally, this misalignment results in uneven twisting in the finished product, poor quality of the yarn.

Therefore, it is essential to check all possible alignments to ensure all are perfectly in their positions and make routine adjustments.

This would greatly help improve the uniformity of yarn produced and probably reduce defects.

Daily Maintenance Practices

Cleaning the Machine

Dust Removal

Dust and lint will accumulate very quickly in the machines, which operate with textiles, thus affecting operation.

Dust can be removed from accessible areas with the use of a soft brush or even with a vacuum cleaner to be effective in an easy and regular activity.

Prevent accumulating that could initiate more serious problems later by keeping it operating smoothly with this simple activity.

Lubrication

In fact, all mobile components need to be lubricated regularly to minimize friction and wear.

Their moving elements must be lubricated appropriately to keep smooth movement between gears and spindles and add-on components.

With a lubrication schedule, all necessary parts will be well covered, ensuring reduced wear while increasing the life of the machine.

Inspection

It is common to visually check the machine for any problems daily.

Evidently, it will include checking for a loose bolt, split belt, or any unusual signs of wear and tear.

All these, if identified before they become full-blown issues, can be forwarded to the service technician promptly and the machine kept in good working order.

Performance Monitoring

Noise Checks

Keeping track of the noises that your machine makes while working can tell you a lot about the health of the machine.

An unusual voice could be grinding or rattling and may have some mechanical causes that require urgent attention; through consistent sound checks, one can identify early on the problems and attend to them before they turn into major breakdowns.

Vibration Analysis

Monitoring the vibrations of the machine is another way of determining its health.

Every excessive vibration or noise indicates some misalignment or inadequacy that will lead to severe mechanical problems in time.

Well-timed and properly done vibration analysis assures that all components have been operating well and then leads to smoother and quality production.

Output Quality

It has to check the quality of produced yarn regularly.

This is because there should be some consistency in the yarn produced, which would reflect that the machine is in proper working condition.

Any deviation in yarn quality from expectation should be investigated without delay to identify and correct the issues to maintain standards.

Read More:

Ensuring Quality When Buying Yarn Twisting Machines

Weekly Maintenance Tasks

Most Detailed Cleanings

Deep Cleanings

The interval between thoroughly cleaning each machine part-from the unreachable-the thorough cleaning blocked from letting things build up for possible performance issues, but all parts are optimally functional.

Less the machine is dirty, fewer operational problems it will encounter, and better quality yarn can be produced.

Replace Filters

If your machine has air filters, replace them regularly to maintain proper airflow.

Clean filters are essential for machine operation efficiency and prevention of overheating.

Regular replacement of filters will greatly improve the overall performance and durability of any machine.

Inspect Belts and Cables

A weekly examination of these belts and cables will ground any signs of gradual fraying or damage to an early stage.

This is very crucial in a machine that effectively acts since this has to be treated at first signs of wear to prevent breakdowns.

Regular checks can ensure that your machine has smooth and unnoticed operation.

Set the Statics

Calibrate Tension

Correct calibration of yarn tension is necessary for twisting efficiency. Its miscalibration might lead to yarn defects: poor quality and inefficient production.

Therefore, continuous checking and tension adjustment guarantee the quality of the output so that it is in tune with the stipulated standard.

Speed Adjustment

The machine needs to adjust the speed continuously whenever a new type of yarn is produced, to get the best quality of finished output, setting these parameters relative to the machine ensures that it is working to the desired parameters for a particular task.

Monitoring Temperature

A constant watch on the operational temperature is essential to avoid damage due to overheating.

Periodic temperature checks will pinpoint such problems before it becomes a bigger issue, thus keeping the machine safe and efficient.

Monthly Maintenance Checks

Specialized Maintenance

Seek Expert Assistance

Many professionals can be hired for expert inspections and servicing.

Their knowledge and experience may discover something during such inspections that regular maintenance may not reveal.

Professional service should give that comforting feeling where the machine is believed to be in tip-top shape and also worry-free for attending to those hazardous concerns.

Software Updates

Your yarn twisting machine may work with software, and thus ensure that it gets updated whenever such is expected.

As much as it keeps the machinery working efficiently, the current software enhances machine diagnostics in identifying probably imminent issues more rapidly and accurately.

Changing of Components

Regularly replacing parts that wear out will help prevent many of such problems.

Keeping a spare parts inventory for immediate replacement does help avoid downtime and keeps production going.

Besides, regular changes within the components can improve overall function for the machine.

Assets Management

Stocking Spare Parts

Quick replacements of important spare components are to maintain the needed enough inventories.

Parts in stock reduce the waiting time and facilitate uncompromising production halted-due to non-availability of parts.

Supplier Relationships

Reliably, good relation built with the suppliers is an extremely important factor to secure the availability of parts on time.

Strong links with suppliers can help you get the components when the need arises enabling fixation to take place without stopping production.

Documentation

Comprehensively documenting all maintenance activities is a crucial predication towards machine performance over time.

This would lead to identifying all recurrent problems to be taken into consideration concerning future maintenance strategies, to keep the machines in the best possible condition.

Troubleshooting Common Problems

Early Identification of Issues

Listen and Look

Continuous surveillance might reveal and arrest troubles before they go out of control and bring in repairs that would have to be made at a higher level or even cause complete equipment failure.

Check the Connections

It is important to regularly check all electrical and mechanical connections for tightness.

Loose connections may create performance problems and require tightening or replacement.

Tightening both mechanical and electrical connections would enhance machine reliability.

Refer to the Use Manual

There would be certain troubleshooting steps specific only to the machine.

Consult the manual because it would contain rescue information for many common problems and their solutions, hence being an important reference point for operators and maintenance personnel.

Instant Solutions

Factory Reset

While it may seem a simple reset to get rid of nuisance, resetting the machine to its defaults may occasionally resolve minor operational issues.

Quick correction usually does not require a comprehensive troubleshooting exercise to get things back to order.

Recalibrating Settings

Most problems with machine performance could often be cured by routinely recalibrating settings.

The changes might include speed, tension, or other adjustments that can improve machine performance and optimal use of the parameters.

Washing Sensors

Keeping them dirty would result in inaccurate readings or possibly not operating at all.

Regular cleaning of sensors ensures that readings are accurate; operations run smoothly, and yarn quality remains consistent.

And More:

Maintenance and Troubleshooting Tips for Automatic Winding Machines in China

Enhancing Machine Longevity

Best Practices for Usages

Operator Training

A training less exhaustive of operator on usage best practices results to maximum minimisation of wear and tear.

Operators so educated mostly would know how to use machines without risk of deliberate damage, in addition, they would use machines more wisely.

Scheduled Downtime

Regular downtime would mean giving machines a cooling-off and resting time to increase life span values.

Scheduled breaks would also serve to maximize performance and to a point lessen the chance of failure in its machinations.

Utilization Guidelines

Guidelines that would be from machine manufacturers for optimum use would be very important for efficient performance while avoiding over-wear at the machine when during use.

Improving Components

Invest in Quality Parts

Whenever you replace components, only high-end replacements should be used.

Quality investment in high-quality spare parts might cost huge bucks in the beginning, but it is likely to be of better performance and durability, thereby saving money in the long run. upgraded

Consider Upgrades

Evaluate whether updating some of the components of the machine leads to better performance.

Technological advancements bring about better efficiency, functionality, and output quality with regular evaluation of your equipment so that you know possible upgrades.

Stay Updated

Discovering the latest technologies and advancements in twisting yarn would provide an excellent reference in improving production processes.

Being informed makes you wise in terms of decisions regarding equipment and maintenance efforts.

Conclusion

Maintaining yarn twisting machines is essential for ensuring efficient operation and high-quality output.

By following these maintenance tips, you can extend the lifespan of your machines, reduce costs, and enhance the overall quality of your yarns.

Regular attention and care will pay off in the long run, making your production process smoother and more reliable.

Investing in proper maintenance is not just about keeping machines running; it’s about ensuring that your business thrives in a competitive market.

Prioritizing maintenance will help you achieve consistent quality and efficiency, ultimately leading to greater customer satisfaction and business success.