Self-operating winding apparatus is a specialized tool. It serves to spool materials.

These materials include wire thread or tape. Sectors of various industries use these. These sectors include fiber optics electronics and textiles.

The mechanism optimizes production processes. It does so by increasing efficiency and precision.

The utilization of these machines is quite diverse. They can handle numerous kinds of materials.

They are also designed to work non-stop. This makes them integral for manufacturers. These manufacturers aim to fine-tune output for maximum effectiveness.

Learn More:

- Automatic Winding Machine Production Capacity & Output Comparison

- Automatic Winding Machines Basic Performance Comparison

- The Most Advanced Automation Technologies in the Textile Industry

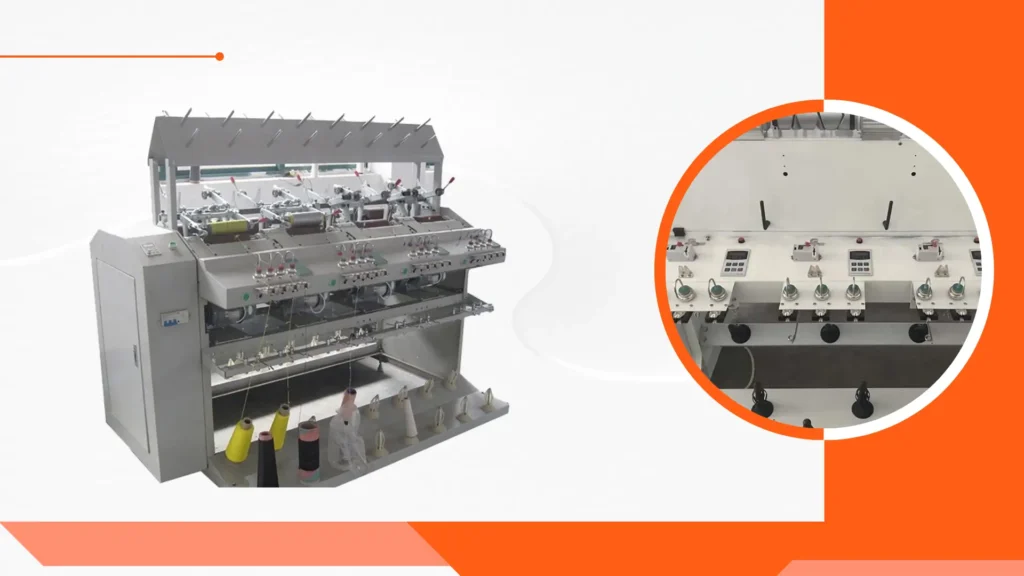

Key Components of the Machine

Fundamental elements in an auto winding machine encompass feed mechanism, winding head, control arrangement and spool holder. Every element holds an important function.

It ensures winding operation is smooth and efficient. The feed mechanism manages flow of material.

Winding head accomplishes winding task. Control system grants operators power to program the machine for different tasks. The spool holder secures spools throughout operation.

Common Applications in Various Industries

Automatic winding machines have applications. They are utilized in industries. These industries are textile, electronics and automotive manufacturing. In textile industry they serve a critical purpose.

They aid in the winding of yarn. For electronics they are used to wind coils. These coils are for transformers. In automotive industry they are used to wind wires.

The wires are used in various components. This adaptability makes these machines valuable. It is a boon for manufacturers. They seek to boost productivity.

Importance of Regular Maintenance

Benefits of Preventive Maintenance

Regular upkeep is vital for automatic winding machines. This upkeep helps in identifying potential issues.

It does so before they escalate. Preventive maintenance makes sure that machines run at peak performance. This reduction in downtime enhances productivity.

Additionally, it increases the machine’s lifespan. It is a sound investment for all manufacturing operations.

Cost Savings Over Time

Regular maintenance investment can lead to significant savings. This happens by preventing major breakdowns.

This way businesses avoid costly repairs. They can also dodge expensive replacements.

Moreover a well-maintained machine works more efficiently. It consumes less energy. It thereby reduces operational costs long term.

Enhancing Machine Longevity

Correct maintenance is crucial to prolong life of self-winding machinery. Regular checks are a must.

Adjustments are crucial as well. These prevent machine from wearing too quickly. It ensures that the machine remains in top condition. This process saves cash.

Furthermore it lessens disturbances in production. This is due to there being a lesser number of unexpected failures.

Daily Maintenance Checklist

Routine Inspections

Conduct the daily inspections. Look for signs of wear, of damage. You should look for loose connections.

You should listen for any unusual noises. Any irregularities in the machine operation are cause for concern. The detection of issues, however small, can prevent serious problems in the future.

Lubrication Requirements

Make sure all moving pieces have enough lubrication. It must adhere to the manufacturer’s specifications.

Right lubrication cuts down on friction. This can cause overheating and a breakdown of the machine. Check lubricants regularly. Add more as needed.

Cleaning Procedures

Keep machine clean. Remove dust and debris. Erase any residue. Clean machine functions efficiently.

It also maintains product quality. Product quality is important in winding products. Plan regular cleaning. This ensures all parts get maintenance. It’s crucial.

Common Issues and Their Solutions

Identifying Mechanical Problems

You can see mechanical problems in various ways. Unusual sounds may come from the machine.

Movements may be erratic. Misalignment can happen during operation. Regular inspections may help to find these problems early. Solutions could consist of different actions.

Tightening parts that may be loose. Replacing parts that are old. Recalibrating the machine may also be necessary.

Electrical Faults to Watch For

Machine problems can also be caused by electrical issues. Watch for blown fuses.

Look for tripped circuit breakers. You might even see inconsistent power supply. Investigating these problems might involve certain steps.

You may need to check wiring connections. You might need to replace faulty components.

Software Glitches and Fixes

Machine operation can be hindered by software glitches. It is important to ensure that the control software is updated frequently. Proper configuration of settings is also crucial. If problems continue you should think about taking action. Resetting the machine could be an option. Consulting the manufacturer for guidance can also be helpful

Troubleshooting Techniques

Step-by-Step Troubleshooting Guide

Issues present themselves. You need to follow a system. This approach needs to be systematic when troubleshooting.

What should you start with? Begin by identifying symptoms. It’s important to consult the machine’s manual. This manual provides needed guidance.

You must test each component with methodology. Such testing can help pinpoint the root of the problem. Additionally this testing can help figure out the source of the issue.

It’s easier when you identify symptoms, consult the manual and test components. When there’s a systematic approach troubleshooting is more effective.

Using Diagnostic Tools

You must employ diagnostic instruments to assess machine performance. They also help to pinpoint issues.

Numerous contemporary machines come featuring in-built diagnostics. These can swiftly reveal problems.

When to Call a Professional

If your efforts don’t resolve the issue call professional technician. Complex problems require expert attention.

Particularly, those involving electrical systems or software. It’s important to ensure safety, effectiveness. Reach out to a professional.

Safety Precautions

Personal Protective Equipment (PPE)

When you wit machinery for winding use right personal protective equipment (PPE).

Mandatory safety glasses gloves and ear protection. Personal safety is essential in manufacturing environment.

Lockout/Tagout Procedures

To prevent accidental startup of machines use lockout/tagout procedures. Implement these practices during maintenance.

It helps to ensure only authorized personnel can operate machines. This reduces risk of injury.

Emergency Shutdown Protocols

Create clear emergency shutdown procedures. In incident follow these. Make sure operators are trained on these protocols.

This will help them react quickly. Think of safety during emergencies. This is of utmost importance.

Upgrading Your Winding Machine

Signs It’s Time for an Upgrade

Check for clues. It may be time for you to think about an upgrade on your winding machine.

These hints can be frequent breakdowns lowering productivity. An inability to keep up with current production demands could be another sign. A machine upgrade can help you stay ahead in the market.

New Technologies Available

More recent winding machines have sophisticated technologies. Automation is one example. Smart controls are another.

IoT connectivity is another. These aspects heighten effectiveness. They also reduce labor costs. Quality of the product also gets better.

Benefits of Modern Machines

If you invest in a new machine it can improve production speed. Accuracy and energy consumption can also be enhanced.

Most recent models are engineered to confront current manufacturing issues. They’re an intelligent decision for forward-thinking companies.

Training Your Staff

Importance of Proper Training

Staff that undergo proper training are essential for effective operation. They are also vital for maintenance of automatic winding machines.

Training is a way to ensure that employees grasp the safe and efficient use of these machines. This comprehension can reduce the risk of errors and accidents.

Available Training Resources

There are numerous manufacturers providing training services. These services are for their equipment.

Besides resources online and workshops are also an option. They provide extra education on top practices and troubleshooting techniques.

Continuous Learning Opportunities

It is important to make staff interested in continuing education. This is for them to stay updated on new technologies and maintenance methods. Holding regular training sessions is beneficial. They can help in upskilling and improving productivity.

Conclusion

To sum up understanding the operation of automatic winding machines is critical. Maintenance is key too. This ensures the machines will work efficiently and for longer periods.

Regular maintenance is necessary. Troubleshooting in the correct manner is also important. Staff training is crucial to successful machine management.

Regular checkups are essential. Preventive measures can cut downtime. This in turn cuts costs and ensures smooth operations.

Your automatic winding machines need care.This emphasis can boost productivity. It can also decrease costs. High-quality output is guaranteed for many years.