In the fast-paced world of manufacturing, machines like automatic winding machines can make or break a company.

An automatic winding machine at peak performance results in the following-payback cycle time, improved quality of production, and considerably reduced operational costs.

Conversely, an underperforming machine can create bottlenecks, cause wastage, and eventually result in customer dissatisfaction.

Establishing those metrics would allow manufacturers to generate an overall profile of a machine’s potential, which would allow them to see which models best coincide with their goals.

Key Performance Indicators (KPIs)

Production Speed and Output

One of the prime KPIs for such equipment is production speed: how long it takes to perform one winding operation.

Fast production speed allows manufacturers to meet the deadline within time for cases of urgent requirements.

Measuring the speed with respect to the industry and the competitor can give an idea of how a machine performs in real life and will produce results that could lead to possible profit loss or gain.

Quality and Consistency

Quality assurance is very important in manufacturing especially precision products.

It is vital to check the quality and consistency of output from a winding machine in terms of defect rates and adherence to product specifications.

Machines that produce high-quality, consistent output minimize rework and waste thus making production cost-effective.

Downtime and Maintenance Frequency

Understanding the downtime and frequency of maintenance of a machine is quite important to measure how reliable it would be.

More breakdown means more time delays in production and affects efficiency in total cost. In many cases, a manufacturer’s assessment of machine reliability includes how often a machine breaks down, how much time it takes to repair, and preventive maintenance.

The less frequent the maintenance requirement to keep a machine running, the more desirable it is.

And More:

Automatic Winding Machines Basic Performance Comparison

Evaluating Efficiency

Energy Consumption Metrics

Energy consumption features are increasingly important as sustainability becomes a concern in manufacturing.

Determining how energy a fully automatic winding machine consumes when taken into operation can help understand savings potential and identify areas for improvement regarding the environmental impact.

Comparative analysis of energy consumption across machines can help manufacturers build a more sustainable environment that equals their mission towards responsibility.

Material Utilization Rates

This is how much of the raw material is used by a machine when producing material.

High utilization is indicative of the fact that it utilizes the material as best it can and wastes affect the cost of using such machines.

That attribute becomes very significant in measuring the economic performance of the winding machine.

Manufacturers may analyze material utilization to determine what simple improvements could enhance the production processes so as to achieve better efficiency at lower cost.

Cycle Time Analysis

The entire winding system including loading, unloading, cutting and shifting of product being wound defines the cycle time.

The study of this cycle plays an important role in understanding the efficiency of any machine.

A machine which would have lesser time cycle would favor overall throughput to work for high production levels.

The continuous monitoring and analysis of cycle time would contribute towards the implementation of changes to enhance even more operational efficiency.

Assessing User-Friendliness

Operator Training Requirements

A machine that is intuitive and easy to operate requires less training time, enabling a quicker entry into production environment.

This ease of use not only boosts productivity but also eliminates the possibility of operator mistakes.

Evaluation about training requirements for different machines helps manufacturers select choices that match their workforces’ capabilities and operational needs.

Ease of Use and Control Systems

The design and functionality of a machine control system play a critical role in its overall usability.

Ergonomic control features will allow the operation easier, and clear displays facilitate an error-free operation.

When making a buying decision about automatic winding machines, the manufacturer needs to consider the operator’s ability to navigate and adjust the control system.

Machine where operators find it easy will encourage greater confidence and efficiency in the operator.

Accessibility of Maintenance Features

Since malfunctioning machines have been a reliable source of reducing production time, easily accessible components for maintenance checks and repairs can significantly reduce machine downtime.

Routine checks are done quickly enough to avoid it becoming a business continuity risk in operations because it has little operational downtime.

Manufacturers should evaluate how easy it is to access critical parts like removals and repairs so that maintenance can be conducted as quickly and efficiently as possible.

Reliability and Durability

Long-Term Performance Trends

The assessment of long-term performance trends in machinery is important in determining the reliability of the machine as time goes by.

The manufacturers should specify the data to be included for study to indicate how the machine has performed under different conditions and volumes of production.

Consistent performance trends indicate the machine reliability and the investment is sound when such a trend has been considered.

Long-term evaluation data enable manufacturers to gain confidence in their purchases.

Wear & Tear Resistance

Functionally, a machine has inherent resistance to wear and tear, usually important in the lifespan of the apparatus.

Knowledge of the materials and construction of automatic winding machines can give an idea of durability.

Their performance remains without failures caused by wear if made from high-quality, broadly strong materials.

The selection becomes very easy because it intends to look at the ability to defeat wear and tear with respect to daily use.

Availability of Spare Parts

For minimizing time lost in repairs, sufficient and immediate access to spare parts is necessary.

Machines that are able to access a steady supply of spare parts will usually draw more interest since they will allow for speedy fixes and continued maintenance.

Manufacturers would need to ask the availability of spare parts while evaluating different models, since this can greatly influence the operational efficiency and cost-efficiency in the long run.

Safety and Compliance Standards

Machine Safety Integration Feature

Importance of safety features in automatic winding machines is to protect the operators and other personnel around them.

Assessing components such as built-in safety mechanisms- emergency stop buttons, guarding systems, safety interlocks- ensures a safe environment in which to work.

Machines built with such an extensive safety lineup comply with regulatory standards and constructs a safety culture within the organization.

No Industry Regulation Compliance

Comprehensive compliance with industry regulations is the ultimate non-negotiable for any manufacturing house.

Automatic winding machines must pass many safety standards and operational standards to work legally and safely inside a factory.

Compliance assessment helps to save manufacturers from legal complexity as well as fines.

Regulation meeting of the machine is paramount to having a reputable and responsible establishment.

Operator Safety Impact

Design or feature of the winding machines and operation has to be user friendly towards operator safety.

It is very important to assess how a machine protects its users as this is critical towards having a safe workplace.

Safety features incorporated in a machine coupled with adequate training resources and conformity with safety standards significantly cuts down accidents and injuries leaving behind a safer and improved efficiency production environment.

Customer Feedback and Reviews

Gathering User Testimonials

Customer feedback constitutes a valuable resource for assessing the functioning of an automatic winding machine.

Testimonials acquired from users will shine an actual light on the performance of the machine, indicating strong and weak points that may not be visible in the technical characteristics.

Positive comments make the machine indicate that it works reliably and satisfactorily, whereas negative observations lead to directing attention toward potential matters needing attention.

Analyzing Common Complaints

Collecting the most common complaints among users brings invaluable insight to performance and user-friendliness of a machine.

While users complain, the manufacturer pinpoints areas for improvement and makes the right purchasing decisions.

Information regarding what bothers existing users informs a potential buyer on what to avoid when selecting a model that best suits the operating environment.

Learning from Industry Peers

Networking with the industry menace brings more flavor when deliberating on winding machines.

Listening to what other people have experienced tends to add such practical considerations that throw other formal assessments to the side.

This way, you’ve got a guide, in the form of mutual advice and recommendations around the industry peers, toward making informed decisions on best practices.

Conducting a Trial Run

Piloting a Project

Before spending a significant amount on an automatic-winding machine, it has the option to set up a pilot project to test the machines in their environments within the production lines.

Such hands-on experience goes a long way in proving how well or otherwise the machine performs under those working conditions, thus revealing strengths and weaknesses which may not be apparent from theoretical considerations.

Real-Time Performance Monitoring

For example, measuring real-time performance metrics during a run-in trial is important to ascertain what a machine is capable of.

This is used to gather data from the trial runs on production speed, quality, efficiency, and how the machine fare against the predetermined expectations.

Real-world data will help determine the viability of long-term use.

Comparative Analysis of Results with Expectations

At the end of a trial run, it is prudent to compare performance results with the original presumptions made prior to the test.

The evaluation above will help manufacturers assess whether the machine meets their targets in production and quality.

With this information, they may learn the gaps between what was expected and the actual performance thus become adept in fine-tuning selection criteria for better decision-making.

Also Read:

A Comprehensive Comparison of Automatic Winding Machines: Efficiency, Accuracy, and Reliability

Making Informed Decisions

Evaluating Collected Data

Collected data associated with performance assessments or feedback from users should be analyzed with great care to reach meaningful conclusions.

It will entail seeking patterns, trends, and correlations for decisions to be made.

Such data synthesis will let the manufacturers understand which of their machines fits well with their operational requirements and goals.

Comparison of Different Models

On evaluating the automatic winding machine, it is important to evaluate different models based on certain metrics-in performance, user ratings and efficiencies.

Such comparison is useful for weighing each machine against the other to know the ones that are most suitable for their needs.

A full comparison guarantees that the final decision will enhance productivity without downgrading quality standards.

Consultation with Experts

Consultation with experts in the industry would give one precious nuggets of information regarding the requirements of automatic winding machines and hints as to what practices would be currently considered mature.

These experts may be abreast of technologies, good practices, and dangers to avoid.

Their handy experience can help manufacturers in proving machines that give them maximum results with minimum inputs.

Conclusion

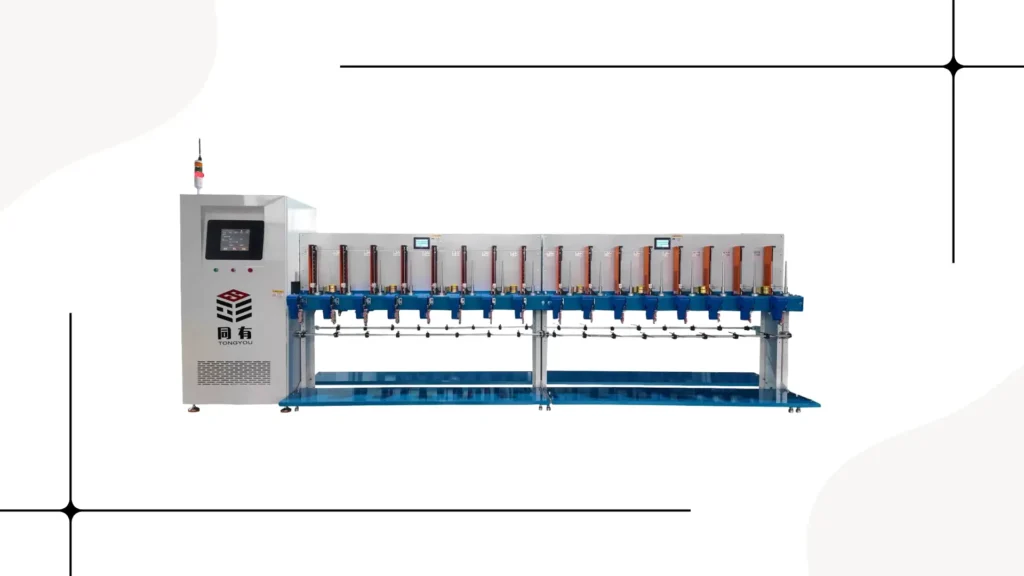

It is evident that assessment performance of automatic winding machines is a critical step toward optimizing production activities.

By understanding key performance indicators and assessing various aspects of machine performance, manufacturers will be able to make enlightened decisions that improve efficiency, quality, and safety.

Before buying, realistic evaluations should necessarily be made and all elements affecting performance assessed.

This ensures that the investment will earn dividends for years to come in harmony with the production goals and operational standards of the company.