In manufacturing’s current quick-paced environment it’s vital to increase output. You can’t however do this at the cost of quality. The factories have this as a key goal. Competition is cutthroat.

Consumers’ expectations are always climbing. Manufacturers must figure out how to enhance production capabilities.

This article delves into a key theme. That’s how modern industrial equipment can be crucial.

It can aid in the attainment of these objectives. The outcome is a more productive and profitable operation.

Learn More:

- Strategies for Reducing Downtime in the Production Process

- How to Choose Automation Equipment to Boost Production Efficiency

- Tips for Enhancing Textile Factory Equipment Efficiency

The Need for Increased Output

Overview of Competitive Manufacturing Landscape

Manufacturing sector is known for rapid technological advancements. It also experiences trends towards globalization.

Companies find themselves in constant competition. They strive for a piece of the market share. Those who fail to innovate, face the grim reality of falling behind.

In this competitive scene increasing output is not merely a beneficial choice. It has become a critical necessity for survival. Manufacturers are obligated to not just match industry trends.

They also need to predict future consumer needs. The aim is to remain always relevant.

Importance of Maximizing Production Efficiency

Maximizing production efficiency aids in reduction of costs. It also helps in meeting demand.

Streamlining operations result in augmented profits. They also enhance customer satisfaction. It is important to optimize every step of production process.

This helps in minimizing waste. It also reduces lead times. Finally it improves overall product quality. Therefore, it is important to invest in right industrial equipment.

This can be a game-changer for manufacturers. It allows them to respond swiftly to changes in market.

Role of Industrial Equipment

How Equipment Impacts Overall Productivity

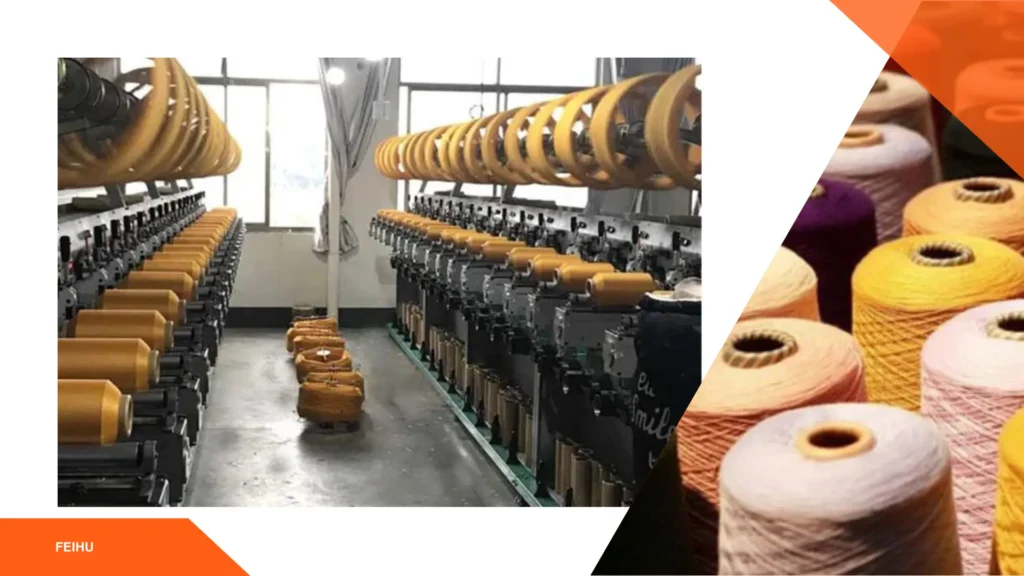

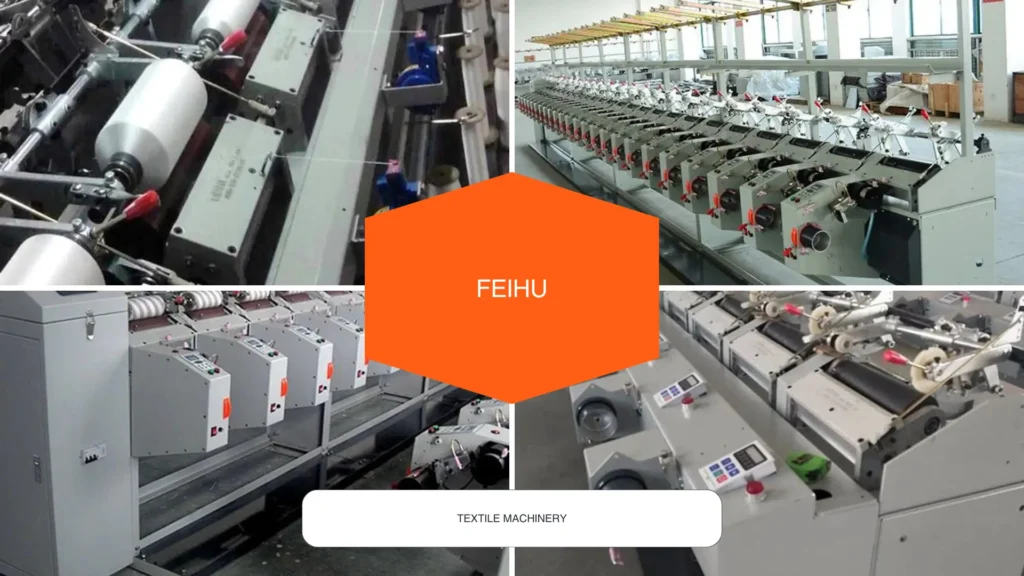

Machinery in industry stands as support to manufacturing. It could be assembly lines or robotics.

The right machinery can remarkably boost efficiency. It minimizes downtime and heightens output.

The production targets will always be met. Machinery of advanced sort could also aid faster setup times.

It could allow for smoother transitions in production. In this way, it further increases efficiency overall.

Key Benefits of Investing in Modern Machinery

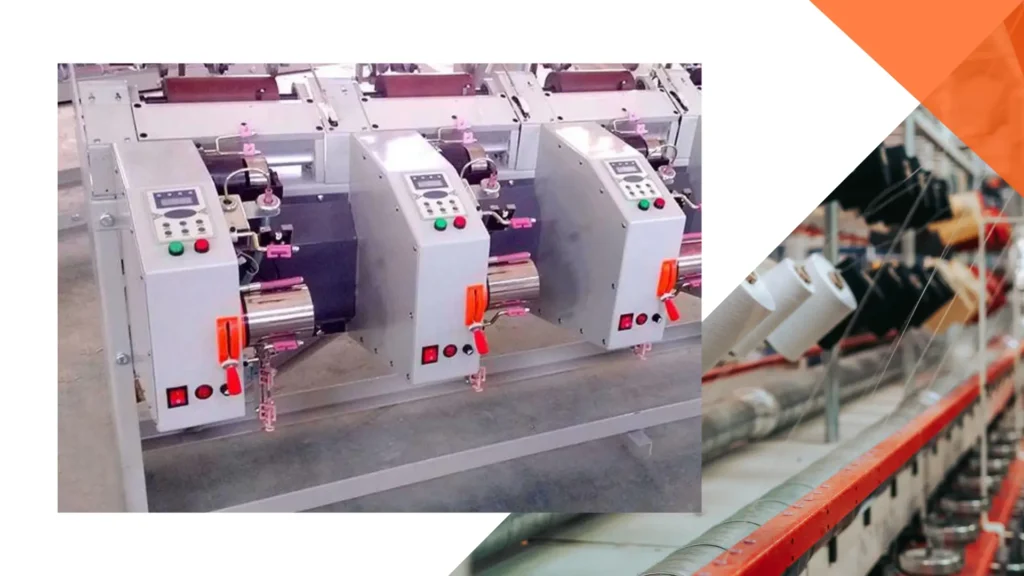

Increased Speed

Often, modern equipment operates faster. This is especially beneficial with tight deadlines.

It also helps high-volume industries. The quicker turnaround time can be a game-changer.

Improved Reliability

Newer machines have technology. This technology is advanced and this minimizes breakdowns.

Production becomes consistent. Reliable machinery equals fewer maintenance and repair needs. This way operations run smoothly.

Cost Savings

The initial investment might be high. Yet, long-term savings in labor and maintenance are substantial.

Modern machines need less manual intervention. This can decrease labor costs. It also enhances safety.

Understanding Types of Industrial Equipment

Categories of Equipment

Conveyors

Given their utility in moving materials along a production line conveyors are highly valued.

They markedly enhance efficiency. Manual handling is reduced. This is one of the significant advantages of using this equipment.

They streamline processes. This too is a notable benefit of conveyors. A smoother workflow is the result. This is due to both the reduction of manual handling and process streamlining.

Robots

Some robots possess the ability to accomplish tasks of complexity. They do it with precision.

With this, need for manual labor can be reduced. Robots are able to function even in hazardous settings. They execute repetitive tasks. This liberates human workers for strategic roles.

They can be employed in a wide array of environments. Robots are a versatile advancement in technology.

CNC Machines

CNC machines permit automated machining processes. High accuracy and repeatability are ensured.

These machines are indispensable in industries that require intricate designs. They are also useful in industries that demand tight tolerances.

For example, aerospace and automotive manufacturing industries are perfect examples.

Specific Functions and Applications of Each Type

Every type of equipment has dedicated applications. They cater to various manufacturing needs.

Conveyors for example are crucial in assembly lines. They move products effectively. CNC machines on the other hand are well-suited for industries needing detailed machining.

Understanding specific equipment roles is important. It aids manufacturers in selecting the right tools.

This leads to enhanced efficiency. It boosts output. It is beneficial for the manufacturing process.

Choosing the Right Equipment

Factors to Consider When Selecting Machinery

Production Volume

Equipment requires to match production output. It has to meet requirements. High-volume operations might need more robust machinery.

The machinery should handle increased demands without compromising quality.

Space Availability

Layout of factory plays critical role in determining machinery. It has to do with the type and size of machinery that factory can fit.

Efficient use of space enhances workflow. It reduces operational costs. Matching Equipment to Production Needs

Matching Equipment to Production Needs

It’s crucial to align equipment with production requirements. This ensures optimal efficiency and output.

An assessment of current and future production goals is needed. It can guide this decision.

Manufacturers should evaluate processes. They should identify bottlenecks. Then equipment should be chosen which directly addresses these challenges.

It ensures a specialized solution. This solution will maximize productivity.

Enhancing Productivity with Automation

Benefits of Automation

Automation is strong tool. It is for increasing factory output. Automation reduces manual labor.

This lets workers focus on complex tasks. Automated systems offer speed and accuracy. Manual processes cannot match them.

Automation enhances safety. It reduces risk of human error. It’s in repetitive tasks. It leads to a more reliable production environment.

Types of Automated Solutions

Robotics

Robots find uses in assembly and welding. Continuous operation with high precision is possible.

They can also adapt to changing tasks. This makes them versatile tools. They are used in modern manufacturing.

Automated Assembly Lines

These systems streamline production processes. Output is significantly increased.

Automated lines can be programmed. They handle various products. This allows flexibility in production.

Suitable Applications for Different Industries

Industries can benefit from automation in unique ways. Take automotive manufacturers for example.

They extensively use robotics. Robots are used for tasks. These tasks include welding and painting.

Precision and speed are necessary for these tasks. Meanwhile let’s look at food processing plants.

They might implement automated packaging solutions. The goal is to increase efficiency. This is to maintain hygiene standards.

Improving Quality Control

Role of Equipment in Quality Assurance

Modern industrial equipment is critical. It ensures product quality. Advanced machinery frequently has features.

These features enhance quality control. Among them are precision sensors and automated inspection systems.

Capabilities like these let manufacturers monitor product quality. They do it in real-time. This reduces the likelihood of defects.

It also ensures compliance. What it ensures compliance with? Industry standards. Manufacturers benefit from these capabilities.

Features that Support Consistent Quality Control

Attributes like real-time monitoring and data analytics help manufacturers. They maintain their high-quality standards.

This is true throughout the production process. Quality control systems are integrated into machinery.

This allows manufacturers to catch problematic situations early. They make necessary adjustments. This ensures every product meets customer expectations.

Implementing Quality Control Systems

Overview of Integrated Quality Monitoring Tools

Quality monitoring tools integrated into production lines lead to instant feedback. This spurs adjustments.

These systems monitor various parameters. These include dimensions, weight functionality. The goal is to ensure product specifications are met.

Importance of Real-Time Data in Maintaining Standards

It allows for identification of quality issues before they escalate. This enables manufacturers to make rapid adjustments.

By using data analytics, factories can improve processes constantly. This ensures they maintain high quality standards.

Optimizing Workflow Efficiency

Streamlining Production Processes

Layout of equipment holds big sway over workflow efficiency. An organized arrangement trims pointless movements.

It maximizes productivity. Manufacturers can create seamless production flow. This is done strategically. Machinery and workstations get positioned right.

Identifying and Eliminating Bottlenecks

Important task is to identify bottlenecks in production process. This is crucial to improve workflow.

By analyzing production data manufacturers can pinpoint inefficiencies. They observe operations to identify delays too. Addressing these issues is important.

This can be done through equipment upgrades and process changes. Such strategies can result in major improvements in overall efficiency.

Lean Manufacturing Principles

Adopting lean manufacturing principles aids in waste reduction. Also it encourages improved efficiency.

It centers on value-added activities. It eradicates non-essential steps. Manufacturers can streamline their operations with these techniques. They can reduce costs too. Productivity also gets enhanced.

Maintenance Strategies for Equipment Longevity

Importance of Regular Maintenance

It’s for ensuring longevity of industrial equipment. A proactive approach is beneficial. It minimizes breakdowns. Also it extends the life of machinery.

This doesn’t just protect initial investment. It also keeps production running smoothly. There are no unexpected interruptions.

Benefits of a Proactive Maintenance Approach

It enhances safety and efficiency. It ensures uninterrupted production.

Regular inspections and timely repairs are also part of this approach. They stop minor issues from growing. This results in a more reliable production environment.

Common Maintenance Practices to Implement

Introduction of practices like structured checks and regular washing, greatly improve machinery performance.

They enhance reliability too. It is vital to organize a maintenance timetable. The schedule includes oiling, alignment processes and component replacements. This guarantees that the equipment operates at top-notch efficiency.

Training Staff for Equipment Care

Importance of Skilled Operators in Maintenance

Operators with expertise have vital role in caring for equipment. Their training guarantees that machinery is utilized efficiently and managed appropriately.

Trained personnel can detect potential issues early. They can manage minor repairs. This improves operational efficiency.

Training Programs that Enhance Equipment Longevity

Investment in training programs equips staff with vital knowledge. This knowledge is required to maintain machinery.

It extends its life and increases productivity. It is essential that training covers right operation techniques. It should also cover maintenance procedures and safety practices.

It prepares employees adequately. They will then be able to manage equipment effectively.

Utilizing Data Analytics

Benefits of Performance Tracking

Equipment performance can be monitored via data analytics. This allows manufacturers to discern trends.

They can then make insightful choices about production processes. Tracking performance helps to evaluate machinery efficiency. It can highlight areas that may need improvement.

Tools for Collecting and Analyzing Data

These tools provide insights. Insights that drive ongoing improvement in manufacturing. Advanced software solutions have potential.

They can integrate with machinery. This integration can collect data in real time.

This enables manufacturers to monitor performance metrics. They can then make adjustments. Data-driven adjustments.

Making Informed Decisions

Using Data to Optimize Production Processes

Decisions driven by data make manufacturers able to optimize their production processes.

Such decisions enhance both efficiency and output. Through an analysis of performance data, manufacturers can pick out best practices. They can streamline operations and induce changes.

These changes lead to better productivity. Hence the improvement process is essential to their functioning.

Case Studies of Successful Data-Driven Adjustments

These implementations are based on data analysis. The results are significant improvements in productivity.

These examples can be great lessons. Manufacturers who wish to use data analytics can learn from these. They can apply this knowledge in their own operations.

Sustainability and Efficiency

Eco-Friendly Equipment Options

Picking energy-efficient machinery is beneficial.

It reduces operational costs. Additionally it boosts a company’s brand image as sustainable business. Equipment that’s eco-friendly uses less energy.

It also creates less waste. It contributes to a production process that is more sustainable.

How Sustainability Can Enhance Brand Reputation

Commitment to sustainability has power. This power attracts customers. These customers prioritize environmentally friendly practices.

The outcome is increased loyalty. It leads to increased market share as well. Companies that show dedication to sustainability gain.

Gain a competitive advantage in the market. They do so because they are seen as environmentally conscious.

Compliance with Environmental Standards

Meeting regulatory requirements proves essential for success in long run. Present-day equipment supports sustainable practices. Manufacturers gain assistance in complying with environmental standards.

By investing in machinery that is eco-friendly. Thus ensuring alignment with regulations of industry and expectations of community.

Conclusion

To increase factory output investing in appropriate industrial equipment is paramount. It’s from productivity improvement to quality control enhancement. It’s also about optimizing workflows.

It is about ensuring sustainability. All these tasks modern machinery carries them out. It plays a significant role in success of manufacturing.

Manufacturing landscape is on a continual evolutionary path. This moment marks an opportune time for factories. I

t is time for them to consider investing. Investing in advanced technology should be the current focus. The advantages exist and they are quite clear.

Output will be increased. Efficiency will increase. Moreover it will foster a sustainable future.