The yarn twisting machines are essential for the textile sector as such machines help the manufacturers to make higher quality twisted yarns for various uses.

As the market requirement for specialty fabrics increases, so does the demand for technology that could manufacture reliable and efficient yarn twisting technology.

This guide is thus intended for all primary information when planning to buy a yarn twisting machine.

Key Benefits of Using Yarn Twisting Machines

Higher Strength of Yarn

Yarn twisting machines increases the tensile strength of yarns significantly.

Their tensile strength increases so much that the defined dimension of that yarn length gets broken under enormous tension.

This enhancement is most necessary to fabric design that is faced constantly with an everyday condition because they are used in some end-products.

Stronger yarns are instrumental in defining the fabric quality and keeping fabric integrity over time by reducing breakage chances.

In some other industries such as outdoor apparel or heavy workload materials, strength preservation that twisting affords could be the clincher on which the success of the product hangs.

Aesthetic Improvement

Twisting provides aesthetic appeal to yarns and may offer various textures and styles.

This versatility allows manufacturers to develop distinctive fabrics and markets.

Twisted yarns can be used for different finishes (some matte, some glossy) dependent on the fibers used and also the twisting technique.

Moreover, the creation of multi-colour twisted yarns allows a designer much space for creativity, making it easy to create mesmerizing textiles that fuse with current fashion practices.

Aesthetic enhancement in products does not only appeal to consumers but also helps the brand differentiate itself in a competitive industry.

Enhanced Production Efficiency

The modern yarn twisting machines are designed with production efficiency in mind such that enormous production of yarn can be achieved with a reduced time span.

This efficiency is attributed to the sophistication associated with advanced technologies in the twisting process, which further enhance shorter setup time and low downtime during production.

Since the quality remains unaffected, the output can jump by leaps and bounds.

Such productivity advancements increase profitability and the ability of companies to meet tight deadlines and need quick responses to market demand.

Further, in fact, labor costs are reduced because fewer operators run the high-output machines.

Lurching Towards Diversity in Yarn Purposes

Giving way to a variety of fibers and yarn types, the twisting machines are engineered to bring forth the versatility to every manufacturer, which can then produce anything and everything from clothing to international textile products.

It is anything within a fast-moving context wherein shifts occur too quickly.

There is thus easy-switching for manufacturers when it comes to different yarn types, for example, cotton, wool, or synthetic fibers, which could lead creative thinking and innovation on new products or fast responses to specific client requests.

Additionally, specialty twisting assemblies will develop one-of-a-kind yarns tailored to highly specific markets such as eco-textiles or technical fabrics for industrial uses, giving that extra touch to business opportunities as well as broadened avenues betwixed the market reach.

Key Features to Consider

Speed and Efficiency

The speed of the machine affects the production rates directly, meaning that high-speed machines would decrease the production time considerably, which in turn should lead to an increased output.

Production may be speeded up, with some additional bonus as to how effective customers can be served in the end.

Buyers should, therefore, seek such machines that can adjust their speed to cover the various yarn types and production requirements.

Flexibility and Versatility

A good twisting machine for yarn is one that can twist high and low counts of yarn types.

This flexibility allows manufacturers to achieve a wide variety of products.

An excellent machine that would fit into one of several materials, for example, cotton and polyester or blends, would broaden the boundaries and market horizons for manufacturers.

Such a machine not only adds to the manufacturer’s ability to have varied products but also could save much cost by eliminating their use for many specialized machines.

User-friendly Design

The user-friendly machines will save time and may make training cost ineffective.

Some of the user-friendly features are the intuitive controls and ease of access to maintenance.

User-friendly, too, would minimize downtime and allow productivity to run without a hitch.

These are the important features that a manufacturer should go for: their machine comes with good manuals and training materials so that its operators quickly become sufficient.

Material Quality and Durability

Importance of Solid Materials

Machines made from quality materials would withstand wear and tear, plugged uptime changeovers for repairs and replacements.

The proposal of using heavy machines, reinforced with strong materials, could always cost far less for future savings.

An essentially built machine would stand the test of time with very little degradation on its performance consistently in case of any failures in the productive quality it delivers.

Corrosion Resistance

Machines that resist corrosion are expected to live longer, especially where there are high atmosphere humidity and chemical exposure.

All the machine parts get corroded, and repairs become expensive when the efficiency reduces.

These machines should be looked for in any protective form coating or produced from corrosion-resistant materials, so the machines would last longer in operation.

Technological Developments

Modern machines, of course, have built-in advanced technology, which makes them more durable and reduces the maintenance intents.

Automated lubrication systems, advanced sensors and predictive maintenance further enhance the performance and reliability of these machines.

Staying technologically advanced reflects better production prospects with lower costs of operations.

Also Read:

Industry-Specific Applications of Yarn Twisting Machines

Cost Considerations

Initial Investment and Long-Term Worth

An initial price can be high but, whatever it costs at the outset, the efficiency and durability of some machines can offer savings over the years.

A machine running efficiently can do away with most of the expenses associated with maintenance, thus offsetting the high initial price with time.

Accordingly, it leads buyers to a good evaluation of total cost ownership, including energy consumption and maintenance.

Operating Expense

Add energy consumption and maintenance costs. Machines that show high efficiency in energy consumption generate savings at the end of the race.

Furthermore, one would have to know the general availability and costs of replacement segments because they would have to plan their budget with respect to further maintenance.

Such machines that are flagged as having a good energy standard and low operational cost runtime should be sought for better profitability.

Financing Options

Examine options for financing or leasing, which can make it easier to buy that high-quality machine.

Most suppliers offer very flexible financing solutions enabling customers to invest in top-quality equipment and manage cash flow effectively.

Understanding the terms and conditions of financing options is important for making a sound investment.

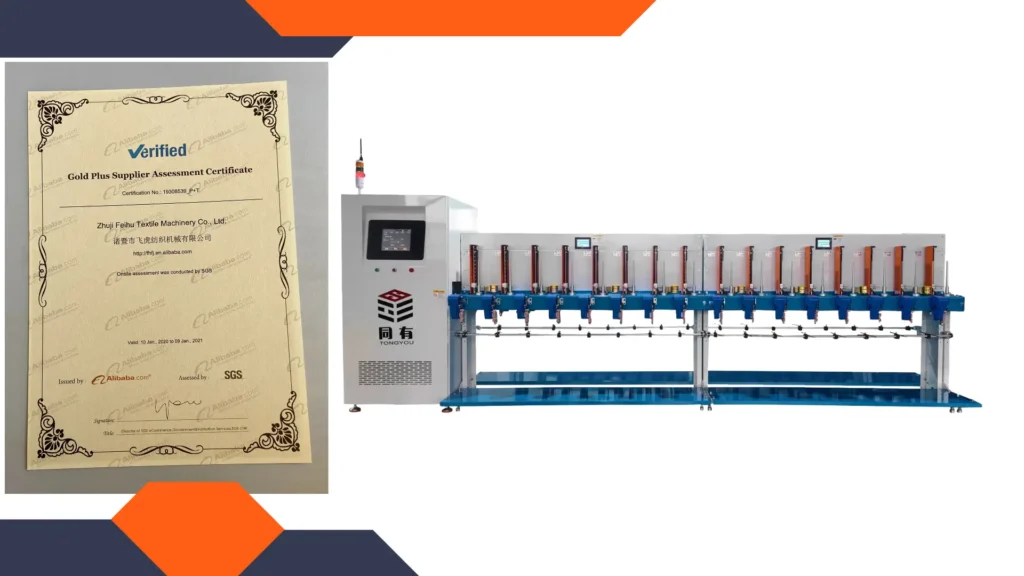

Supplier Reputation and Support

Supplier Background Investigation

Always look for suppliers who have a proven track record in the industry from customer reviews and testimonials.

A well-regarded supplier is more likely to give their customers quality machines plus dependability.

Buyers will also look for suppliers who specialize in their respective industry and are known for their innovations.

After-sales Support

Find out what after-sales support is available, including maintenance services as well as warranty options.

An effective after-sales support system can really add value to a machine.

Priority should be given to suppliers who offer complete warranty packages and have a call center to handle customers’ queries even after making the purchase.

Training Library and Resources

Training resources from suppliers can assist your team in maximizing the efficiency of your machine.

Such training can minimize operational mistakes and maximize peoples’ productivity.

Buyers must find out about training materials, workshops, and ongoing support to ensure the team can operate the new machine.

Environmental Impact

Green Technologies

Machines composed of environment-friendly features, such as energy-efficient motors and materials, can now be viewed in the market.

The environmental manufacturing process will then be a value-added factor of a company, making it attractive to a continually increasing number of eco-conscious customers.

Machine sustainability design also contributes towards operational cost reductions.

Waste Reduction

Machines designed to minimize waste can contribute to a more sustainable production process.

For example, yarn twisting machines have been proven to optimize the material utilization while producing lower quantities of scraps, leading to cost savings with a smaller environmental footprint.

Buyers should therefore purchase machines that encourage waste reduction as part of their operational capabilities.

Regulatory Compliance

Ensure the machine complies with environmental laws and standards applicable in your country or sector.

Compliance with environmental regulations not only protects a company from potential fines, but also enhances its reputation as a responsible manufacturer.

Buyers should check out if the machines they consider are compliant with all relevant standards.

Conclusion

For a textile manufacturer, the purchase of a yarn twisting machine is a critical investment.

With proper understanding regarding key features, costs, and supplier characteristics, buyers can make informed decisions that could yield great success in production.

Quality and support will lead to investments resulting in the best benefits for your business.

The machine should be able to yield higher productivity, better quality of products, and long-term profitability for your textile operations when chosen well.