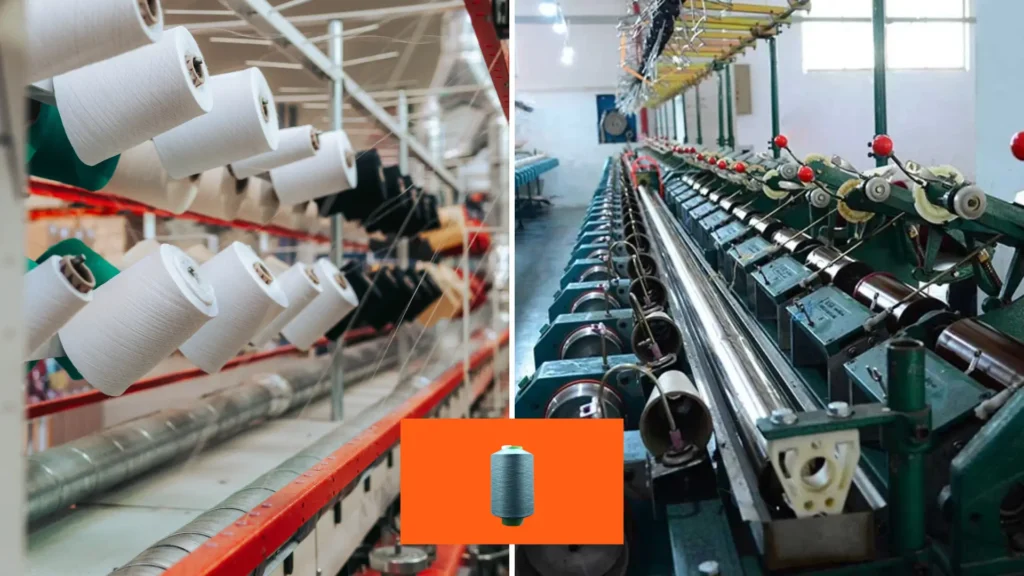

Yarn twisting does not only pose a mechanical function; it also plays a vital role in the final quality of the products.

Such twisting gives yarn its strength, thereby not allowing easy fraying and breaking during use.

Twisting is indeed seen as an important aspect of yarn production, so manufacturers develop and twist their yarns differently to be able to meet the demands of most of their customers.

Yarn twisting machines are available in different configurations, such as single-twist, double-twist, and specialty machines, suited to different fiber types.

A single twist machine would mainly be able to handle the basic applications of twisting yarns while a double-twist machine would have the advantage of additional strength and elasticity.

Specialty machines may handle unique fibers or specific twisting techniques for the manufacture to be able to customize their production bases depending on the required market demand.

Therefore, the different varieties are useful for business managers in selecting the right equipment that they want.

Identifying Specialized Production Needs

Production Requirement Assessment

An assessment of all these is done typically before a manufacturer customarily modifies a yarn twisting machine.

That involves weighing the fiber used, the characteristics desired in the yarn produced, and the production volume.

A thorough analysis of these things allows a business to learn the specific features or capabilities that the twisting machine should-have regarding the operation.

Market Analysis

Current market trends are also key areas of interest for manufacturers wishing to customize their production techniques.

It is through the trends that new understanding can be researched for production needs aligned with the customer in order to encourage innovation for greater competitiveness in the market.

Customer Information and Preferences

Contact the customers directly to know their yarn preferences.

For example, conducting surveys and interviews may end up giving important information regarding which specifications turn out to be very important to them, say, softness and durability, or even eco-friendliness.

Then it may be integrated into what manufacturers will achieve using custom yarn products.

Benefits of Customizing Yarn Twisting Machines

Extended Production Efficiency

Increased production efficiency is probably the most important aspect of customizing yarn twisting machines.

When matching the capabilities of the machinery to the production processes, manufacturers can streamline operations and, as a result, shorten production time and reduce waste.

The increased efficiency alone converts to cost savings and increased output, enabling businesses to meet rising uptakes without sacrificing quality.

Yarn Quality to Customize

Customizing yarn twisting machines allows manufacturers to create yarns with specific qualities for particular markets.

Whether in achieving the desired texture, strength, or elasticity, the capacity to modify twisting settings would ensure that the end product will meet the requirements of customers.

Such customization can give further value to competitive differentiation among firms in the textile industry.

Profit Making

A customized machine will be largely costlier than a standard machine at the initial outlay. However, often benefits would outgrow costs within a period.

Very large amounts of money could be saved by improvement in quality and lowering of production errors thus reducing wastage and rework.

With time, savings become huge and the production process cheaper, creating a scenario for increased profits without sacrificing high standards.

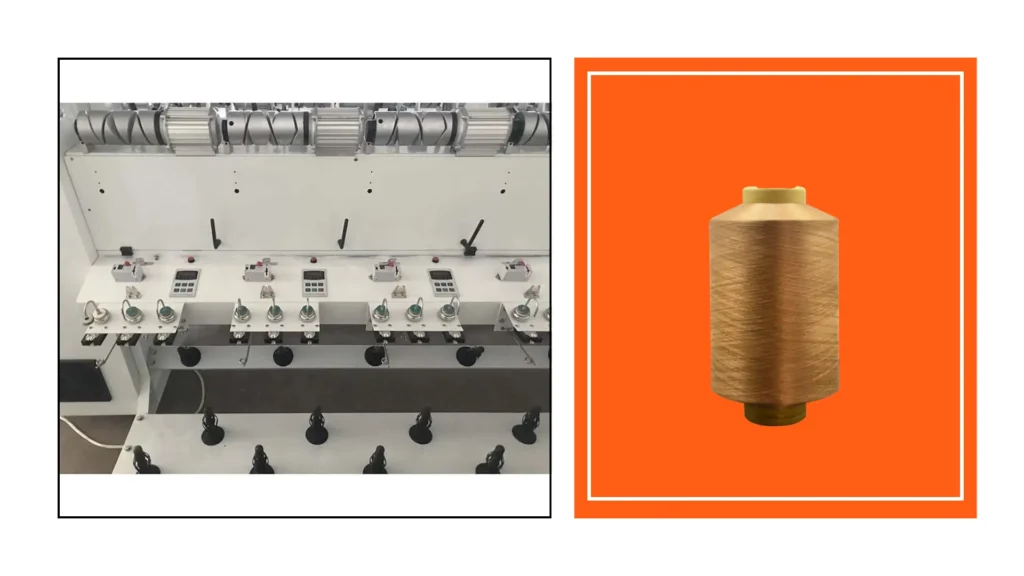

Key Features to Consider in Customization

Flexibility in Twist Levels

The adjustment of twist levels is one of the most significant features because it helps to produce yarn to meet the different needs of the customers.

And according to their use, the yarns can be of any type, even the extremely delicate fine strands or the thick, coarse strands, thanks to adjustable twisting provision.

User-Friendly Controls

The technology is changing and adding a lot of complexity to machines.

And if you do happen to have these machines called yarn twisting machines, then it must have very user-friendly controls.

So, the operators get to learn new machines fast; there are not many chances of faulty errors occurring during the operation.

Such measures make the machine available to all the workers, enhancing productivity and safety.

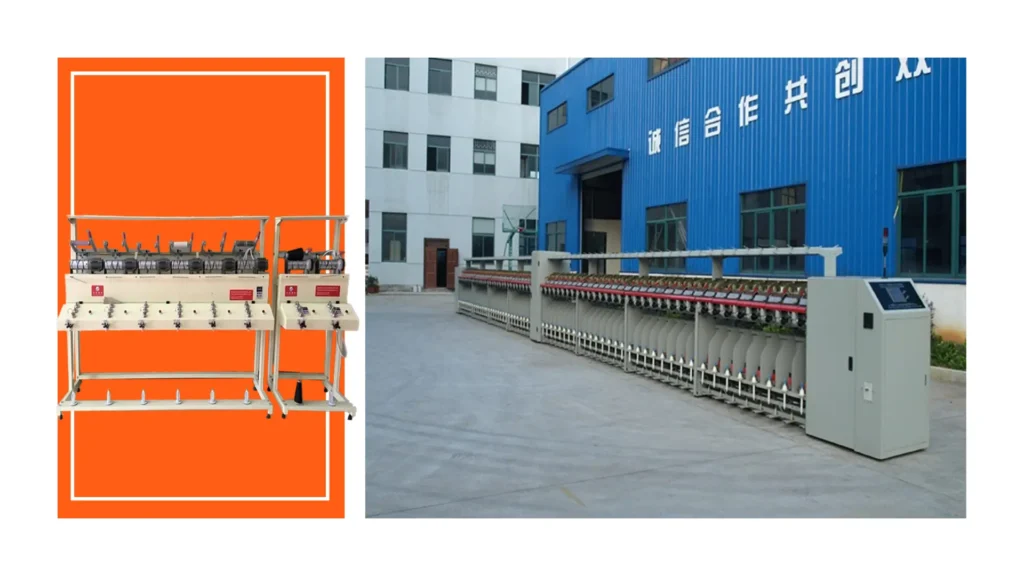

Well Integrating Complementary Machine

There is also a factor that manufacturers must keep in mind when customizing the yarn twisting machines: how well the produced new machine shows in integrating with existing production equipment.

Integrated equipment allows one to operate in an efficient way because work will run evenly without much downtime at the time of transition from one operation to another.

Assessing compatibility with current systems is crucial in maximizing the effects of new machinery.

Also Read:

- Ultimate Guide to Selecting an Automatic Winding Machine Manufacturer

- Application of Smart Equipment in Modern Factories

Role of Technology in Customization

Artificial Intelligence-Driven Automation

The integration of smart automation with yarn twisting machines is transforming the textile industry.

Such advanced technologies could monitor machine performance, make automatic adjustments, and provide real-time information regarding production metrics.

Such smart automation will help improve production efficiency, reduce human error, and keep quality evenly distributed on yarn production.

Modern Materials

Today’s modern materials in yarn twisting machine construction will make significant differences in machine performance and longevity.

Quality components will enhance durability and reduce maintenance and downtime.

When you use advanced material, expect your machines to take the unrelenting force of nonstop production and translate that into better overall reliability.

Data-Driven Decisions

With data analytics, manufacturers will improve machine customization decision-making.

After all, production data alerts the business to trends, performance metrics, and potential improvement areas.

Overall, data-driven benefits place manufacturers ahead of the game in their ability to optimize machines for production needs while competing in a fast-paced, ever-changing market.

Collaborating with Machine Manufacturers

Finding the Right Partner

It is necessary to select the appropriate partner to custom-build yarn twisting machines.

The partner has to be established, experienced and resourceful in the quality commitment.

A reliable partner would also offer insights and recommendations to give that extra-mile assurance that the customized machine will work towards achieving production goals.

Knowing about the Customization Process

There has to be an effective communication between the manufacturing company and the customer so that a customer can understand the customization processing.

Capability, time frame, and restriction should be implemented.

This would create a better approach for each side in producing good results with high satisfaction levels.

Assessment of After-sale Support and Maintenance

Ongoing support and maintenance are critical for the life of the yarn twisting machines.

Organized training, and readily available technical support offered by the manufacturers are part and parcel of offering customers satisfaction at the end of the machine life cycle.

Thus, assessment of the support provided will ensure that the machines run without a hitch during their life span.

Future Trends in Yarn Twisting Technology

Eco-Friendly Production

In future yarn production, sustainability will be another factor that will be applied in the textile industry.

Yarns are increasingly being produced using machines that encourage the green way of manufacturing such as energy efficiency and recyclable materials, thus manufacturer increasing concern for sustainability.

In doing so, companies not only fulfill increasing consumer demands but also establish themselves as responsible industry leaders.

Automation Growth

A trend which has been to develop further in the direction of automation in manufacturing processes seems to lead to more and more advanced yarn twisting machines to be developed that do not require much human effort and thus allow engaging the manufacturer to focus on innovation and improvement of quality.

Automation would ultimately give consistency and efficiency and with that an advantage for the whole production.

Customization as Standard

With the growing demand for specialty yarns, customization will probably start becoming the industry standard.

Manufacturers adopting this trend will be better poised to meet an even greater number of diverse needs and preferences of their customers.

This change will also encourage more innovation and encourage continuous improvement within yarn twisting technology.

And More:

Verifying the Credibility of Yarn Twisting Machine Suppliers

Conclusion

Most importantly, customizing the twisting machines is a requirement to meet the production needs of a manufacturer.

Businesses can enhance their production process and when in the manufacturing process employ higher-quality yarns by understanding the importance of the twisting machines and identifying unique requirements while engaging the right partners.

Embracing all the technological advancements and attuning themselves to the future will ensure that manufacturers have a competitive hold in a continuously evolving market.