Automatic winding apparatus are key in various sectors. They include electronics textiles and automotive production.

These apparatus make the process of winding automatic. This leads to a rise in efficiency. It also leads to more precision in manufacturing.

Businesses are trying to improve their processes. The choice of a dependable manufacturer is vital. A manufacturer with a good reputation can offer high-quality machines.

This article will walk you through the factors to consider. These factors are crucial when choosing the right automatic winding machine manufacturer.

Understanding Automatic Winding Machines

Definition and Basic Functions

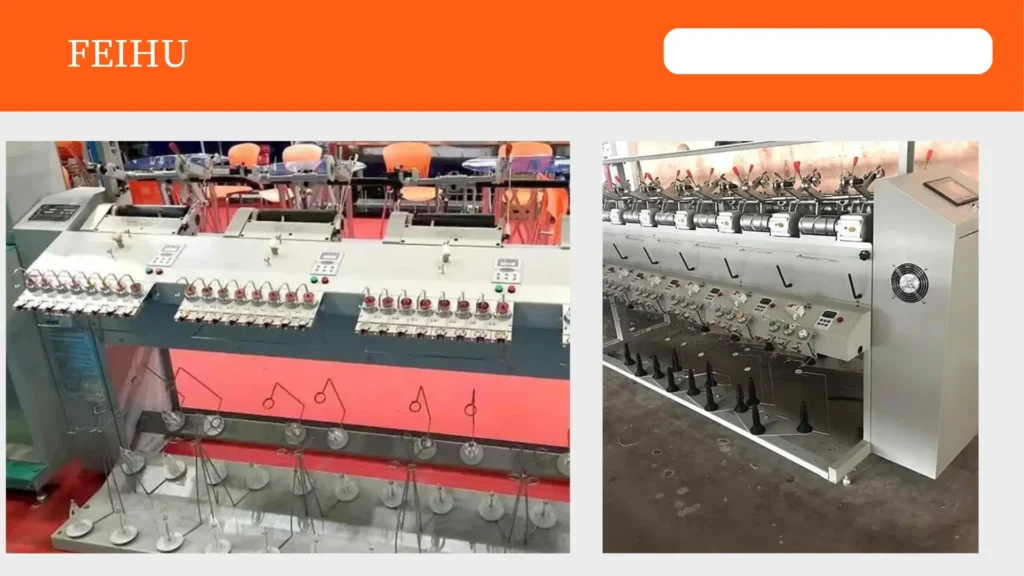

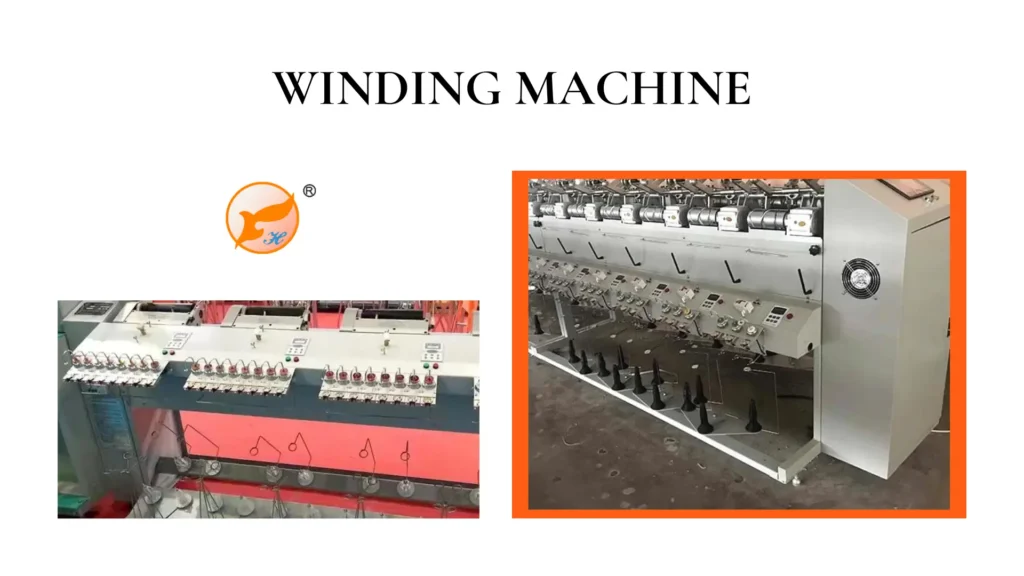

Automatic winding machine is specialized. It helps wind materials. Examples of materials are wires and threads.

It also includes fibers onto spools or drums. Machines function with minimal human oversight. They use advanced technology for uniformity. Also for precision in the winding process.

These machines can handle diverse winding patterns. They can work at different speeds and tensions. They are versatile for different applications.

Electronics

Manufacturing in electronics requires winding machines. They serve for winding coils.

These are in transformers, inductors and motors. Precision is key in this realm. Why? Quality of winding directly affect electronic component performance.

Textiles

The textile industry finds itself dependent on automatic winding machines. They are necessary.

Winding yarn and threads onto bobbins is a process requiring streamlining.

Speeding up production is key. Threads must be wound evenly. That is crucial for processes like weaving or knitting.

Automotive

In automotive manufacturing winding machines play a significant role. They are used for winding wires.

Wires are incorporated in electrical components and motors. Integrity of crucial electrical systems in vehicles is maintained with the help of these machines.

Key Features to Look for in Manufacturers

Quality of Machinery

When you select manufacturer make sure to give priority to those known for making high-quality machines.

It’s important to look for manufacturers that utilize strong materials and advanced engineering techniques.

A machine that is well-built will not only have a longer life but will also need less maintenance. This will save costs for you in the long run.

Customization Options

Each business carries unique requirements. These are based on production processes.

Good manufacturer ought to provide customization options. This lets you tailor machine to meet your winding needs.

Tailoring could involve adjusting winding speed or control of tension. It might involve specialized tooling for diverse materials too.

You might have requirements that are unique or unconventional. A good manufacturer should understand this. They should work with you to provide a solution that satisfies these needs.

Technical Support and Service

Support that follows purchase holds importance. It aids in successful operation of the machine.

The manufacturers you choose should extend comprehensive technical support services. These services must include installation and operator training. Troubleshooting aid is crucial too.

This support guarantees that machines maintain operational status. They also continue working efficiently, cutting down on downtime. Also, it helps to maximize productivity.

Evaluating Manufacturer Reputation

And More:

- Essential Factors to Consider When Choosing an Automatic Winding Machine

- A Comprehensive Comparison of Automatic Winding Machines: Efficiency, Accuracy, and Reliability

Customer Reviews and Testimonials

Essential step is researching feedback from customers. This step is crucial in evaluating reputation of a manufacturer. One should look for reviews on manufacturer’s site.

Look at independent review platforms as well. Positive testimonials are valuable. They give insight into experiences of others. This helps one gauge reliability and quality of manufacturer’s products and services.

Industry Certifications and Awards

Manufacturers that have industry certifications indicate commitment to quality.

Certifications can also indicate compliance with industry standards. This is crucial for maintaining integrity of production processes.

These recognitions provide assurance. They confirm that you partner with a reputable company.

Such a company prioritizes customer satisfaction. The quality and excellence this company offers are unmatchable.

Comparing Prices and Value

Importance of Getting Multiple Quotes

Market Research

Gathering quotes from various manufacturers is key first step in comprehending pricing scenario for automatic winding machinery.

This procedure implies contacting different suppliers asking for comprehensive pricing details. By amassing different quotes, you can gather insights on market price average.

Identifying Value

Once multiple quotes are obtained comparing services and features is the next step. Each offer has to be scrutinized.

This method exceeds only examining the price. It delves into an evaluation of overall presented value from every manufacturer.

This empowers you to determine which machinery yields a higher investment return. You should make sure your choice is not based solely on the price.

Avoiding Overpayment

Use data from assorted quotes. It empowers you to negotiate improved conditions with makers.

When you have knowledge about competition’s pricing and offerings, you can initiate talks confidently. This strength empowers you to request discounts.

You can also ask for additional services. Seeking better terms of guarantee can help you steer clear of overpaying for machine.

Understanding market environment can keep you from falling for excessive pricing or unessential extra items. These items do not align with your demands.

Understanding the Balance Between Cost and Quality

Long-term Considerations

Considering the long-term factors has great importance. For automatic winding machine cost evaluation, think about the initial purchase price’s impact. Reflect on the long-term performance and the maintenance costs.

It is critical. A cheap machine may save you money at the beginning. What if it lacks durability? If it needs frequent repairs those savings can quickly disappear.

Investing in a machine of higher quality may result in better things. Lower operating costs could be one. Over time you might see increased productivity.

Assessing Hidden Costs

Uncover possible hidden costs linked to inexpensive machines. These costs can comprise of frequent repairs and replacement parts.

They can also include heightened downtime due to machine malfunctions. Also a machine of lower quality may not perform efficiently. It could lead to increased energy use and wasted materials.

Thoroughly assessing these expenses is crucial. By doing so, you evade the trap of choosing a machine based only on its selling price. Consider performing a total cost analysis of ownership.

This analysis considers all the costs linked to the machine’s use over its anticipated lifespan.

Making Informed Decisions

Ultimately aim is to select a machine. This machine must strike the best balance. It must balance affordability and reliability.

Making informed decisions is necessary. Consideration of operational needs is needed. Specific ones. Also think about long-term goals.

Look for machines. Find ones with essential features. Look for these features at a competitive price.

Do not forget to pay attention. Attention must be towards the manufacturer’s track record. Check its quality.

The Benefits of Working with a Reliable Manufacturer

Long-term Support and Maintenance

Reducing Downtime

Key benefit of joining up with trustworthy manufacturer is their potential to offer swift support when issues arise.

Downtime in production can be expensive. This leads to missed deadlines and lost revenue. Trustworthy manufacturer will have responsive support team. Team can quickly address technical problems.

This ensures machinery operates smoothly. Proactive approach not only helps maintain production.

It also minimizes disruptions, permitting your business to consistently meet customer demands.

Service Packages

Many manufacturers offer maintenance packages. These include regular check-ups and servicing. Such packages make sure your machines work at peak efficiency.

This happens throughout their lifespan. Regular maintenance can identify potential issues. These can escalate into major problems. Eventually you will save time and money.

Build a Partnership

Selecting a reliable manufacturer goes beyond transactional relationship. It can result in a valuable long-term partnership.

Trustworthy manufacturer will take time to understand your unique operational needs. They will be invested in your success.

This partnership can manifest in ongoing support. It can also show in regular communication. It can be visible in flexibility to accommodate your changing requirements.

Access to Innovative Technology

Investment in R&D

Established manufacturers prioritize research and development (R&D). This is a means to enhance their product offerings. By investing in R&D, these manufacturers innovate.

They continuously improve their machinery. This commitment to advancement ensures you receive a product. This product incorporates the latest technologies and best practices.

Latest Advancements

Choosing reputable manufacturer is to gain access to leading-edge technology. Technology enhances your operational efficiency. It boosts product quality. Advanced features are present too.

Automated controls are there. IoT connectivity is present. Enhanced safety measures are part of the package. Streamlining production processes is the aim. Reduction in labor costs is the result.

Competitive Edge

In today’s market, you must keep pace with technological changes. This is necessary for maintaining an edge over others in industry.

Joining forces with manufacturers who put emphasis on innovation is key. It helps your business adapt to new technologies quicker and in better ways.

This agility offers you the chance to respond to market trends. At the same time you can improve your product offerings and enhance customer satisfaction.

By exploiting the most recent progress your business can set itself apart.

It can separate itself from competitors.

Additional Considerations When Choosing a Manufacturer

Supply Chain Reliability

Supply chain reliability is critical for a manufacturer. One needs assurance that the manufacturer has a proven track record for delivering machines punctually. Moreover, they must provide the necessary parts.

The support for future maintenance is vital. A reliable supply chain works to reduce the risk of production delays. Consequently it helps to keep your operations functioning smoothly.

Warranty and Return Policies

Understanding warranty and return policies is indeed crucial while buying equipment. A manufacturer with robust warranty demonstrates faith in their product quality.

Additionally return policies that are clear can give peace of mind. These policies allow you to return or exchange equipment if expectations not met.

Future Trends in Winding Technology

Automation and Smart Technology

Future of winding technology rests in automation and in smart technology. Increasingly manufacturers are integrating IoT into winding machines.

This allows for more precise monitoring and control. This exploration can help in efficiency and in product quality enhancements.

Sustainability Considerations

Industries are moving towards sustainable practices. They consider manufacturers who make eco-friendly solutions a priority.

They opt for machines that lessen waste. Also they consider machines that reduce energy consumption.

By choosing a manufacturer that supports sustainability a company can enhance its reputation. It also contributes to a greener future.

The reputation of the company is enhanced. This reputation will contribute for a green future. A sustainable future is the need of the hour.

Conclusion

Selecting correct automatic winding machine manufacturer is crucial. It can significantly impact success of business.

Key factors such as machinery quality manufacturer reputation and ongoing support, must be taken into account. This will help in making well-informed choice. It will align with operational needs.

Take time to thoroughly research and evaluate there are plethora of choices after all. By doing this we ensure investment in automatic winding machine yields possible results.

It optimizes production processes. Always remember well-chosen manufacturer can be valuable partner. Involved in growth and success of the business.