The reasons being, automatic winding machines have gained their hold in the contemporary industries due to the automation of winding materials like wires, cables, and textiles.

With these machines, production is more efficient and minor errors by humans can be minimized, hence a consistency in the quality of the products.

Manufacturing industries in the country have started to become modernized, with a fast movement towards complete automation and the application of intelligent technologies.

Automatic winding machines play an indispensable role in several industries that have moved to advanced manufacturing practices, sustaining high output levels while ensuring quality benchmarked to international standards.

It is, therefore, against this background that the following blog post intends to show the many benefits that automatic winding machines can offer to the manufacturing industry in China.

In what follows, we give facts transparently and comprehensibly so as to support buyers in making their decisions as regards how these machines can actually transform production efficiency, cost management, and product quality.

Learn More:

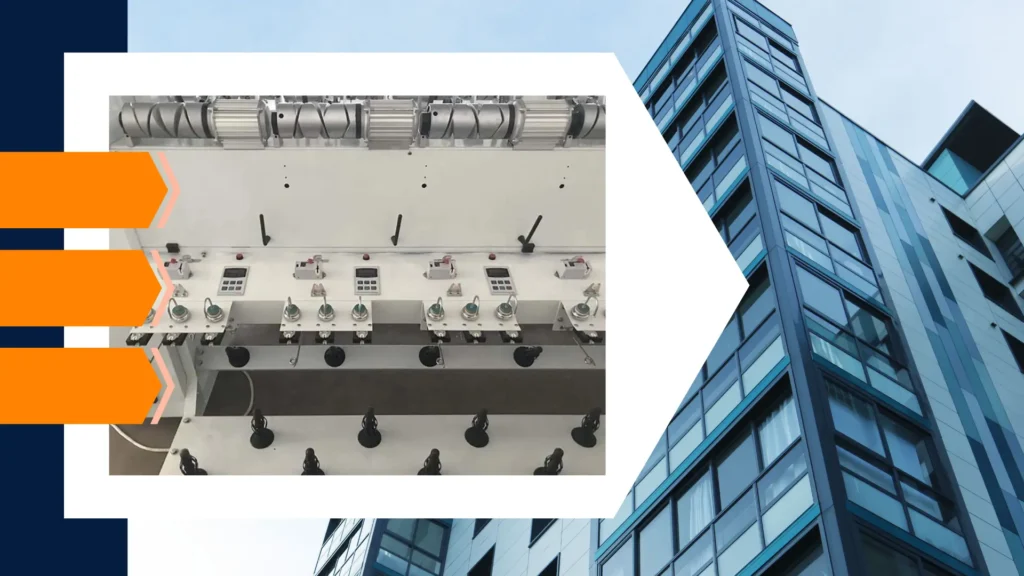

Introduction to Automatic Winding Machines in China

Improved Production Efficiency with Automatic Winding Machines

Explanation of How to Streamline Production Processes

These automatic winding machines are designed to carry out repetitive operations with tremendous speed and accuracy.

By automating the winding process, the time spent per unit is greatly reduced; therefore, producers can offer more products within a shorter frame.

This is important in streamlining processes necessary for meeting high demand and gaining competitive advantages within the marketplace.

Comparison of Production Rates

Comparing manual winding to automatic systems shows fantastic differences in the rate of production.

Manual operators may wind around 100 units per hour, while in that same hour, automatic machines may wind over 500 units.

Such enormous increases in output not only boosts productivity but allows for more substantial orders to be completed and for quicker reactions to the market demands as well.

Examples of Increased Efficiency

These include reports from many manufacturers of electronic goods concerning significant increases in the volume of production after integrating automatic winding machines into their assembly lines.

Such an increase in productivity helps firms fulfill increased demand without yielding to quality compromises.

This may also show quantifiable benefits that automation could contribute towards making manufacturing more efficient across the sector.

Cost Savings from Implementing Winding Automation

Analysis of Initial Investment Versus Long-Term Savings

While this is true, the initial cost of an automatic winding machine does seem uneconomical, yet one needs to take into account the long-term benefits it carries with it: over time, when labor costs are lowered with minimal material waste and increased production rates.

With a proper cost-benefit analysis, it could show that the increased expenditure will be returned through the benefit of increased profitability.

Discussion on Reduced Operational Costs Due to Automation

Automation of the winding process drastically reduces manual intervention and, hence, payroll and expenditure associated with training and benefits.

Secondly, automatic machinery normally requires less maintenance and undergoes less downtime than manual operations, further reducing operation costs.

All this cost reduction enables the manufacturer to utilize resources more effectively and make investments in other areas of growth.

Impact on Overall Profitability for Manufacturers

This means that for any manufacturer, it will result in better efficiency, reduced cost of operation, and hence higher profit margins.

The increased output of automatic winding machines is directly indicative of greater sales potential.

The financial boost could be such that the firm can reinvest that money in its business in creating new products and thereby improve their competitive position in the marketplace.

Quality Control Enhancements via Automatic Winding Solutions

Overview of Quality Control Challenges

Most manual winding processes are prone to irregularities and errors, which have an impact on product quality.

Easy fatigue or distraction by operators leads to defects in products that may affect the integrity of the finished products.

This variability can burn a hole in the reputation of any manufacturer and even result in costly returns.

Ensure Consistent Quality

Fully automatic winding machines have guaranteed that evenness and precision of the wind at each and every moment. Indeed, with sensors and control systems, these machines are able to detect errors and correct them in real time to maintain high quality standards.

It is this consistency that is most needed by those manufacturers who deal with high-quality control standards and tight customer expectations.

Examples of Improved Product Quality and Reduced Defects

This has, for many textile manufacturers, resulted in a great reduction of product defects after the introduction of automatic winding machines.

This leads to a better customer satisfaction and higher rates of approval while reducing the numbers of returns and rework claims.

These are just a few of the possible outcomes which show how automation improves the product quality and reliability across different industries.

Reduction in Manual Labor through Winding Machine Automation

Examination of Labor Costs

Labor costs are the large percentage of cost in the manufacturing of any product, particularly in labor-intensive operations like winding.

With rising labor costs each day, manufacturers sometimes have to make compromises between price and quality to maintain profit margins.

Automation in winding operations saves them partially from such costs.

Benefits of Reducing Reliance on Manual Labor

By minimizing manual interference, manufacturers can reduce human error and further improve their output.

Wind turbine automated winding machines require less manpower, hence businesses could clean up their workforce and put workers in more skilled positions.

This shift in work not only makes them more effective but also a lot safer.

Discussion on Workforce Reallocation and Skill Development

In turn, automation liberates human resources to invest in the development and retraining of the workforce.

Manpower can be upgraded to higher technical jobs, hence infusing job satisfaction and productivity.

The relocation of human resource leads to a more skilled workforce that is better equipped to handle advanced manufacturing technologies.

Technological Advancements in Automatic Winding Machines

Overview of Recent Innovations

Recent developments in winding technology involve the incorporation of smarter control systems and more user-friendly interfaces to make machines easier to operate.

In fact, these developments also allow for greater adaptability and tailoring of the process of winding according to requirements for various products, making them more versatile and efficient.

Impact of Industry 4.0 on Winding Machine Capabilities

Industry 4.0 has really transformed the capability of winding machines through integrated IoT technologies, making them capable of monitoring processes in real time and gathering data directly. This allows connectivity for manufacturers to study key performance indicators, optimize processes, and predict maintenance, thus enhancing operational efficiency.

Future Trends in Automatic Winding Solutions

In the future, the development of automatic winding solutions will include AI and machine learning technologies.

Therefore, this new development will enable machines to learn operating conditions and adapt changes in production demands for maintaining efficiency and reducing downtime.

Environmental Benefits of Winding Automation

Discussion on Energy Efficiency of Automatic Machines

The automatic winding machines are designed to consume less power and, as a result of that fact, are energy-efficient compared to manual ones.

This reduced consumption of energy will reduce the cost of operation and further reduce the ecological footprint coming from manufacturing processes.

Reduction of Waste and Resource Consumption

In automatic rewinding, the winding is optimized, and there is lesser material waste.

This goes a long way in conserving material and aids many manufacturers in going green by enhancing their operations towards appealing to the environmentally conscious consumer base.

Contribution to Sustainable Manufacturing Practices

Automation enables manufacturers to position themselves along the lines of global sustainability goals.

This approach has great avenues for improved reputation and competitiveness in the market, which is increasingly valued for eco-friendliness by way of greatly minimizing waste and energy consumption.

Challenges and Considerations in Implementing Automation

Potential Barriers to Adopting Automatic Winding Machines

Regardless of the above many benefits, adaptation by manufacturers may be hindered in one way or another.

High initial costs, resistance to change among staff, and the complexity of new technologies have made this transition more complicated.

Strategies for Overcoming Challenges

The manufacturer should take a full cost-benefit analysis and involve early stakeholder communications to overcome these challenges.

Manufacturers are supposed to invest in training programs and expertise advice to make their transition smooth regarding automation.

Importance of Training and Support for Staff

Adequate training imparts workers with the skills of using and maintaining the new machines to achieve maximum benefit from them.

Ongoing support of resources to the staff may motivate a positive response towards automation, which would facilitate successfully integrating automation into the manufacturing process.

Conclusion

Fully automatic winding machines have a wide range of benefits linked to efficiency, cost cuttings, quality control, and reduced dependence on human resources. These can be sufficient reasons why manufacturers should adapt to automation.

As the Chinese manufacturing landscape develops, the implementation of automatic winding technology is bound to ensure competency and sustainability.

Such advancement will importantly help in realizing global growing demands at high quality.

It encourages studying the advantages that automatic winding machines have and how such solutions can enable the manufacturer to upgrade operations.

An investment in automation secures future success for a business in today’s fast-moving market.