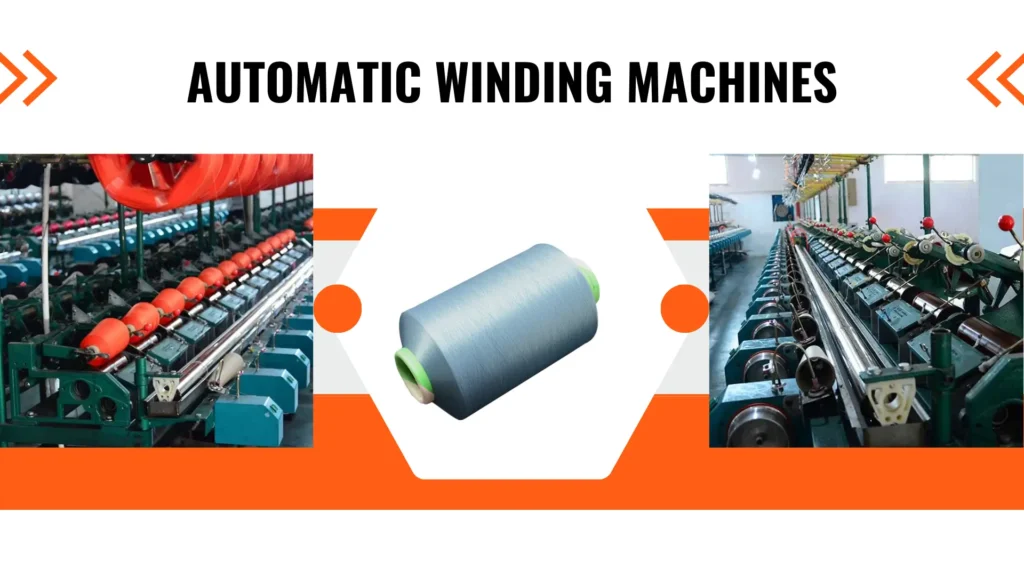

Investing in automatic winding machines offers numerous advantages for your business.

First and foremost, they enhance productivity by allowing for longer continuous operation without fatigue, which is a significant benefit over manual winding methods.

These machines also improve product quality by maintaining uniform tension and reducing the risk of errors.

Additionally, they can lead to cost savings in labor and materials, ultimately boosting your profit margins.

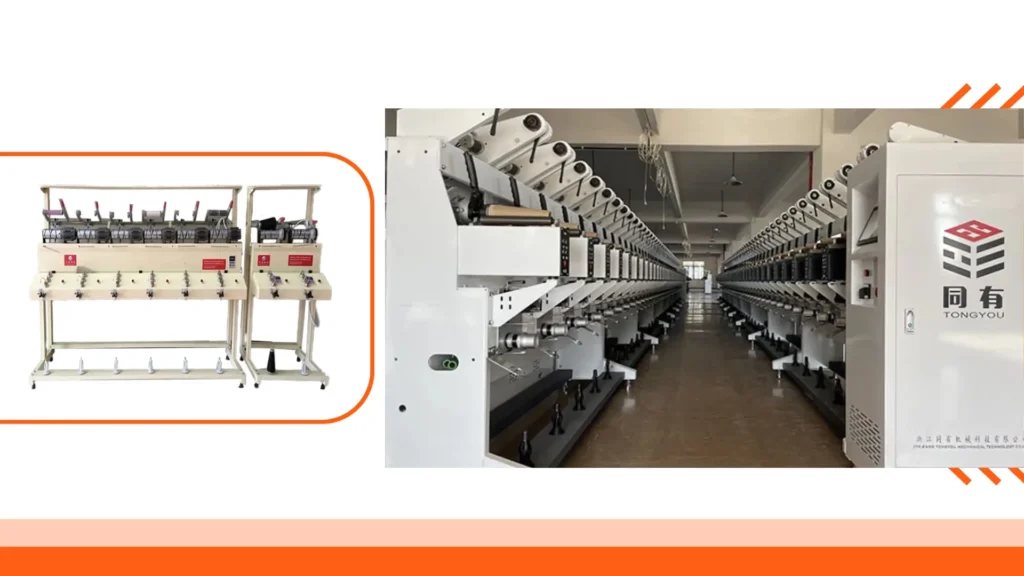

Automatic winding machines are versatile and find applications across a wide range of industries.

Common uses include textile manufacturing, where they wind yarns and threads; electronics, for winding wires and cables; and packaging industries, for winding films and tapes.

Their ability to handle different materials and configurations makes them indispensable in modern manufacturing processes.

And More:

- Maintenance and Troubleshooting Tips for Automatic Winding Machines in China

- Safety Precautions When Operating Automatic Winding Machines in China

Understanding Machine Components

Main Parts of an Automatic Winding Machine

An automatic winding machine consists of several key components, including the spool holder, winding head, tension control system, drive motor, and control panel.

Each of these parts plays a vital role in the overall operation of the machine.

Functionality of Each Component

Spool Holder

This component securely holds the material spool, allowing for smooth unwinding during the winding process.

Winding Head

The winding head is responsible for wrapping the material around the spool. It moves back and forth to ensure even distribution.

Tension Control System

This system regulates the tension of the material being wound, ensuring consistency and preventing breakage.

Drive Motor

The drive motor powers the machine, enabling the winding head to move and the spool to rotate.

Control Panel

The control panel allows operators to set parameters such as winding speed and tension, facilitating easy operation and adjustments.

How Components Work Together

All these components work in harmony to achieve a smooth and efficient winding process.

The drive motor activates the winding head, which moves according to the programmed settings.

The tension control system continuously adjusts the material’s tension, while the control panel allows operators to monitor and modify the operation as needed.

This synergy results in high-quality winding with minimal manual intervention.

Getting Started with Operation

Setting Up the Machine

To begin operating the automatic winding machine, first ensure that it is placed on a stable surface and connected to a power source.

Load the material onto the spool holder, making sure it is correctly positioned to allow for smooth unwinding.

Adjust the spool holder and winding head as needed to accommodate the specific material type.

Basic Operating Procedures

Once set up, power on the machine using the control panel. Select the desired winding speed and tension settings based on the material specifications. Once everything is configured, initiate the winding process. Monitor the machine during operation to ensure it functions correctly and make adjustments as necessary.

Safety Checks Before Starting

Before starting the machine, perform essential safety checks.

Ensure that all guards and safety covers are in place, and inspect the machine for any visible wear or damage.

Make sure the workspace is clear of obstructions, and that emergency stop buttons are accessible.

These precautions help prevent accidents and ensure a safe operating environment.

Maintenance Essentials

Daily Maintenance Tasks

Daily maintenance is crucial for the optimal performance of automatic winding machines.

Start by cleaning the machine to remove dust and debris that can affect operation.

Check the tension control system to ensure it is functioning correctly, and lubricate moving parts as recommended by the manufacturer.

Conduct a brief inspection to identify any potential issues before operating the machine.

Weekly and Monthly Maintenance Tips

In addition to daily tasks, schedule weekly and monthly maintenance checks.

Weekly inspections should include checking the alignment of the spool holder and winding head.

Monthly maintenance should involve a thorough examination of all electrical components, tightening loose connections, and replacing any worn parts.

Keeping up with these tasks helps prolong the machine’s lifespan.

Importance of Regular Inspections

Regular inspections are vital to maintaining the efficiency and safety of automatic winding machines.

They help identify potential issues before they escalate into major problems, reducing downtime and repair costs.

By staying proactive with maintenance, your machine will operate more reliably and efficiently.

Troubleshooting Common Issues

Identifying Frequent Problems

Even with regular maintenance, issues may arise during operation.

Common problems include inconsistent winding tension, material breakage, and machine jams.

Recognizing these issues early can prevent further complications and ensure smooth operation.

Quick Fixes for Minor Issues

Many minor issues can be resolved with simple adjustments.

For instance, if you experience inconsistent tension, check the tension control settings and make necessary adjustments.

If a material break occurs, inspect for any obstructions or misalignment in the winding head.

Regularly checking these components can save time and frustration.

When to Seek Professional Help

While many issues can be resolved internally, some problems may require professional assistance.

If you encounter persistent issues that you cannot troubleshoot or if there is significant damage to the machine, it is best to consult a qualified technician.

Seeking professional help ensures that repairs are conducted safely and effectively.

Enhancing Efficiency

Tips for Optimizing Machine Performance

To maximize the efficiency of your automatic winding machine, regularly review and adjust the winding speed and tension settings based on the material being used.

Experiment with different configurations to find the optimal settings that yield the best results without compromising quality.

Adjusting Speed and Tension Settings

Fine-tuning the speed and tension settings can have a significant impact on productivity.

For lighter materials, a lower speed may be more effective, while heavier materials may require higher speeds and increased tension.

Understanding the characteristics of each material will help you make informed adjustments.

Utilizing Technology for Better Results

Incorporating technology, such as advanced monitoring systems or software, can enhance the machine’s performance.

These technologies can provide real-time data on production rates and efficiency, allowing for informed decision-making and further optimization of the winding process.

Safety Protocols

Essential Safety Gear for Operators

Safety should always be a priority when operating automatic winding machines.

Operators should wear essential safety gear, including gloves, safety glasses, and protective footwear.

This gear helps prevent injuries and ensures a safer working environment.

Common Safety Risks and How to Avoid Them

Common risks associated with operating winding machines include entanglement, electrical hazards, and noise exposure.

To mitigate these risks, ensure that all safety guards are in place and that operators are trained on safe operating procedures.

Additionally, maintaining a clean and organized workspace reduces the likelihood of accidents.

Emergency Procedures to Follow

In the event of an emergency, it is important to have clear procedures in place.

Operators should be trained on how to quickly shut down the machine and access emergency stop buttons.

Regularly reviewing these procedures can ensure that all employees know how to respond effectively in case of an emergency.

Cost Considerations

Initial Investment vs. Long-Term Savings

While the initial investment in an automatic winding machine may seem significant, the long-term savings it offers can outweigh these costs.

By improving efficiency and reducing labor needs, these machines can provide a substantial return on investment over time.

Understanding Maintenance Costs

It is important to factor in maintenance costs when evaluating the overall expenses associated with an automatic winding machine.

Regular maintenance is necessary to keep the machine running smoothly, but proactive care can prevent larger, more costly repairs in the future.

Evaluating Return on Investment

To evaluate the return on investment (ROI) of your automatic winding machine, consider both the cost savings from improved efficiency and the potential increase in production capacity.

Analyzing these factors will help you determine the machine’s overall financial impact on your business.

Conclusion

In conclusion, automatic winding machines offer significant benefits for businesses looking to enhance their production efficiency.

Understanding the machine’s components, maintenance requirements, and safety protocols are essential for successful operation.

By implementing best practices, companies can ensure optimal performance and longevity.

When selecting an automatic winding machine, consider factors such as the type of material you will be winding, desired production capacity, and available space.

Evaluating these criteria will help you find the best machine to meet your business needs.

For more information on automatic winding machines, including specifications, manufacturers, and industry standards, consider reaching out to industry associations, attending trade shows, or consulting with experts in the field.

These resources can provide valuable insights to help you make informed decisions for your business.