When it comes to the manufacturing business, efficiency is key for most company’s growth targets.

To achieve the maximum outcomes from the task, choosing an appropriate automatic winding machine becomes necessary.

Millions of different models and makes are in circulation, hence it becomes important to do some comparative analysis of these machines in relation to efficiency, accuracy and reliability in order to help guide the consumer purchase decision.

Consequently, this publication intends to present an easily acceptable version of these considerations, which assist the potential buyers of such machines in their decision taking process.

Understanding Key Performance Metrics

Efficiency as a Measurement.

Efficiency, in the context of automatic winding machines, is the capacity of the machine to deliver a significant amount of work with very little waste.

This encompasses the processing speed and also how effective the machine is in winding crossings.

Role of Precision

Precision is an important aspect especially when it comes to handling winding operations since it greatly impacts the work that will be done.

A quality winding machine that can make fundamental winding parameters consistently and with a high level of accuracy will always be valuable as it will reduce rejects so the products meet the required quality levels which is very important, particularly for the productions like Electronic and Automotive Industries.

Explanation of Reliability

The term reliability is extensively used in industries to portray how reliable a machine is performing in terms of continuous operation without any faults. In winding applications, a steady winding machine is important as maintenance costs are reduced due to less downtime in production and services.

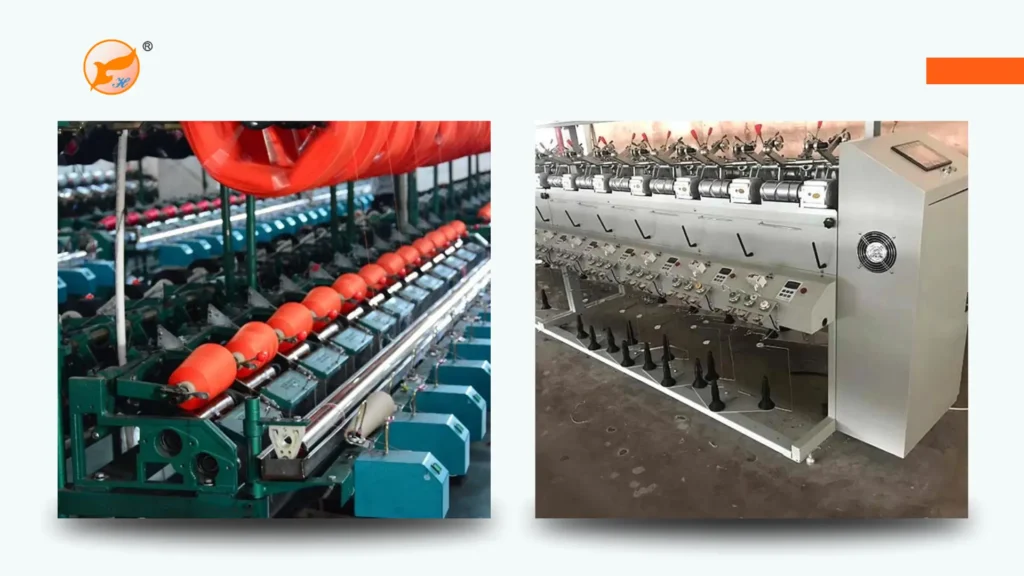

Comparing Efficiency Across Models

Performance and Volume

When looking at different machines, typically the first thing one needs to check is the efficiency of each machine.

Some automatic coil winding machines specify their maximum output levels but the speed at which the machines work should also be seen in practice situations.

Power Consumption

Doing better at something does not mean merely doing that thing quicker, power utilization also matters.

The use of machines that do their work at a higher level will result in fewer activities requiring more electricity, in turn, costing less money to run.

The assessment of the electrical consumption of every system is a tool which helps in reducing the other costs of a business like the utility bills.

Effect on Product Costs

One should understand the impact of efficiency on total costs for production. If a machine is effective, functions can be complete within a shorter period, hence less labor cost, minimizing the amount of materials wasted, and reducing energy operation for which the concern is profitability.

Evaluating Accuracy in Winding Machines

Winding Quality Aspects

It is seen that different machines use different winding methods which can definitely affect the precision of the winding.

For instance, precision can be better for such as the one having a servo motor or the other one closed-loop system, as technology therein is better than for the traditional winding machines.

Tolerances

Tolerance levels refer to the closeness with which a winding machine can be expected to adhere to stipulated constructions.

When in better tolerances, the less tolerances an equipment operates at, the better the quality of the finished product and this is even more crucial where there is high level of accuracy.

How It Affects the Finishing

It can easily be seen that the effectiveness of a winder more specially its winding accuracy will translate directly into that of the material being processed. Messy winding of existing products is improper and can result in wastage of warranted time and resources.

Non-conformity in workmanship also destroys the reputation of any person or institution leading to losses in the long run.

Assessing Reliability of Different Brands

Durability and Design Quality

Every product’s lifespan is essentially defined by the kind of materials that have gone into producing it and the way in which each of its component parts are designed.

When quality components are emphasized in a product one can expect that the product will surpass exceptions under any kind of stress.

Maintenance Requests

There is a significant proportion of equipments which is either regularly maintained or requires continuous attention.

It is always helpful, therefore, to consider the maintenance status of different brands before selecting particular brand machines.

User testimonies on dependability

Consumer reviews can provide some valuable insights on the performance of the equipment in question.

Parsing real user feedbacks can help identify pros and cons of the equipment and help consumers identify what to expect from their investment.

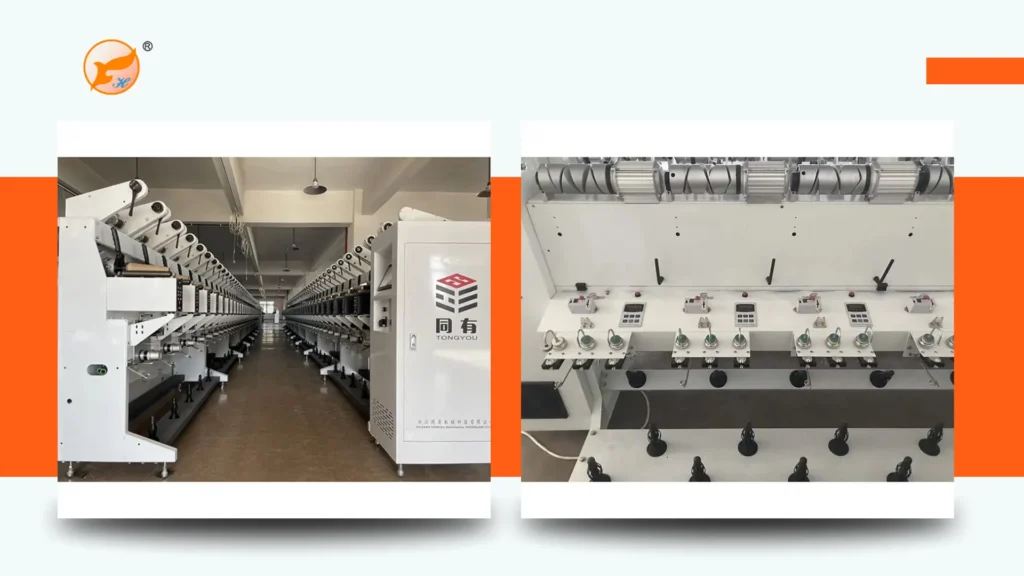

Case Studies: Performance of Leading Brands

Zhejiang Feihu Machinery Co., Ltd. – Optimal Efficiency and Accuracy

Zhejiang Feihu Machinery Co., Ltd excel in producing high speed and extremely accurate machinery – which does not tend to disappoint.

In practice, this has led to decreased manufacturing time, but not once has it affected the quality.

And as such it is not difficult to understand why it is the preference for many manufacturers who are interested in both aspects.

One also cannot but give the manufacturer credit because apart from all these, their machining systems are always equipped with the latest technologies howbeit for improvement of the capabilities in the systems of specific user-applications.

Wuxi Huake Machinery Co., Ltd. – Dependability and Customer Satisfaction

Wuxi Huake Machinery Co, Ltd most importantly have shown for designing the most dependable machinery.

Most customers are also happy on the fact that there is a lot of equipment failure and maintenance is minimal even after a long time of use.

Its emphasis on heavy duty and high-performance machinery has made it a facility that can easily be recommended for a manufacturer looking for equipment capable of quality performance in their coils winding activities.

Shenzhen Wanshen Technology – Pioneering Quality within Reach

There are great numbers of machines that are manufactured by Shenzhen Wanshen Technology Co., Ltd., and all of them are balancing performance and prices.

The users of these equipment do not regard this as a drawback as these models are both efficient and quick paces while being absolutely modestly priced.

This makes Wanshen an interesting choice for smaller scale operations that are in need of exact machinery that will not lead them to bankruptcy, hence involving them in a more aggressive competitive stroke.

User Testimonials and Experiences

Endorsement

Several clients of the company have accompanied positive findings along particular lines of the given models implementing enhanced output and minimized machine failures.

Most often, such affidavits highlight the operational change that has been achieved with certain machines.

Issues in Focus

Majority of the users express satisfaction, however, a few categorically state that they have been successful yet, encountered such problems as difficult in the beginning moving the device around and the use of the machine following the instructions.

Knowing such challenges helps lower the threshold for new purchases.

What Users Say

Users’ testimonials can become a very big fit for potential purchasers.

In particular, many experienced users will encourage prospective buyers to focus on a product in comparison to others along the line of features that have caused distribution and share of service and how well they have done in relation to converting the potential to current users.

Factors Influencing Performance

Capabilities of the Winding Machine

The functioning of an automatic winding machine in specifics with regard to the strength of its motor as well as speed and what materials it can wrap affect its general effectiveness.

Purchasers ought to inspect these data carefully to check if they meet their production expectations.

Work Environment of the Machine

The climate in which the machine is should also be taken into account for it can affect its efficacy.

Variables like temperature, humidity and amount of dust can alter the efficiency and dependability of the machine and, therefore, such factors must be looked into when choosing a model.

Train on the Job Function

How the function of the machine can be carried out by the operator can largely affect the overall functionality of the machine.

A competently enabled staff is able to maximize the work function of the machine in way that no time or resource is wasted, hence reducing the operational cost of the undertaking.

Future Trends in Automatic Winding Technology

Improvements in Speed

No surprise these days, the automatic winding business is ever evolving, always geared to raise its efficiency.

Devices such as IoT integration and advanced automation, which are yet to germinate, also serve the purpose of facilitating the machines and decreasing their costs.

Achievements in Precision

It is envisioned further machines in the future will be able to integrate more advanced features to enhance the precision aspects such as AI features for immediate monitoring and adjustment of winding parameters for winders, leading to better accuracy and reduced rework.

Improvements in Endurance

Because of the need for durable designs, more innovative and effective materials will be developed as well as more user-based techniques will be developed so that these machines can last more than the current practices of repairing and servicing equipment every few years.

To conclude

In this context, the functioning efficiency, precision as well as the robustness of the winding machines, calls for comparison in order to provide an objective basis for making a vendor choice.

When criteria for the evaluation of the available machinery market are determined, along with user-satisfaction, and the reputation of the brands, shall help the potential customers to obtain the best suitable machine for use, if.

Moreover, in such an era, where technology is developing in an unprecedented haste, keeping up with the latest trends will also help in not only surviving but even flourishing what is otherwise a very tough business environment.