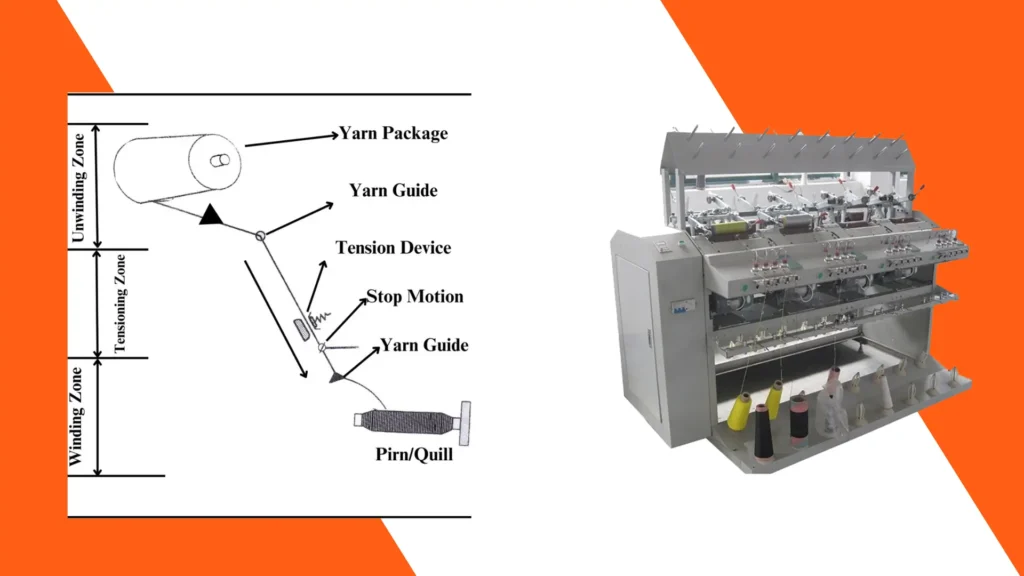

Automatic winding machines are complex industrial machines that can wind any material such as thread, wire, or tape around a spool or bobbin.

Unlike manual winding methods, the machines are characterized by precision and speed and therefore an ideal in an industrial setting.

Automated winding machines are chiefly characterized by sophisticated mechanisms and with controls which ensures the entire winding process occurs both efficiently and uniformly.

They can easily be designed for automatic adjustments in tension, speed, and winding patterns for very high customization according to the specifications of the material being wound.

They are essential in the industries such as textiles, electronics, automotive, aerospace, etc.

The technologized machines can bring a boost in production capacity while keeping the work quality intact.

Such apparatuses become a favourite with manufacturers looking to improve their production capabilities.

Also Read:

What is an Automatic Winding Machine, and How Does It Work?

Increased Efficiency and Productivity

Faster Production Speeds

Automatic winding machines can run at a much faster speed than any manual methods.

High speed leads to high production rates and therefore proper demand can be fulfilled without any compromise on quality.

Continuous Operation with Minimal Downtime

An automatic winding machine is capable of continuous operation and can run tirelessly with minimal downtime needed for adjustments or repairs.

This results in an overall increase in productivity.

It is very useful for businesses that require high volumes of production.

High Output with Consistent Quality

With the help of machines, automation provides that consistency which one could find hard to achieve through manual methods.

Each spool produced will have equal quality standards, thereby reducing the limitations those usually accompany hand-wound products.

And More:

The Role of Automatic Winding Machines in Boosting Production Efficiency

Improved Precision and Accuracy

Constant Tension Regulation

These advanced systems are synonymous with consistency as they maintain their tension throughout the winding process in addition to eliminating many other issues, example uneven winding, all of which can affect the performance of the end product.

Exactness in Winding Configurations

High precision allows these machines to produce complicated winding patterns, that enables the manufacturers to design products that meet a given technical requirement.

This is critical in industries where strict specifications of products are concerned.

Lessened Errors and Wasted Material Consumption

Automatic winding machines reduce the chances of errors to almost zero.

The wastage of materials is reduced significantly, thus making the process quite efficient.

And More:

Key Features to Look for in an Automatic Winding Machine from China

Cost Effectiveness

Reduced Cost of Labor

Lesser manual labor is required for winding since the whole process is automated.

Thus, reducing overall labor costs for manufacturers. They can use their human resources into other critical activities and optimize the workforce.

Reduce Material Wastage

Automatic winding machines reduce the wastage of materials with superior accuracy and uniform quality: that saves material costs and enables more sustainable manufacturing practices.

Long-Term Investment Return

The initial investments made on automatic machines for winding can bring very significant returns in the long run.

The efficiency and reliability of the machine will achieve lower operational costs and higher output. Thus, they prove worthy for future investment.

Enhanced Flexibility and Customization

Adjustable With Different Materials

Automated machines for winding have convenience where it comes to winding different materials, from the delicate wires less than a millimeter thick to the strongest wires.

Thus, through one single machine, a manufacturer can do many products instead of holding many machines.

Settings Customizable for Various Applications

The customization of settings enables one to program the winding process depending on application.

One can modify speed, tension, and winding pattern to allow a manufacturer to optimize the machine for his needs.

Integrated Hence Always in Current Applications

Automatic winding machines can, without difficulty, introduce themselves into the current production lines.

It is going to be a great relief to manufacturers who want to try using advanced technology without altering entire systems.

User-Friendly Interface and Automation

Intuitive Operator Controls

Modern automatic winding machines typically incorporate user-friendly interfaces, which easily allow operators to control and observe the winding process.

As a result, these systems reduce the time needed to teach the new operators and improve productivity.

Automated Adjustment and Monitoring

These methods are also equipped with self-regulating systems that assess in real-time the winding activity and apply the necessary adjustments as required.

Consequently, it offers an even better quality assurance and eliminates possible human error.

Remote Operation Capabilities

With further technological advancements, most automatic winding machines now have the potential to remote control some operations.

Operators can easily manipulate and monitor their machines from a distance, making production management more flexible and responsive.

Maintenance and Reliability

Decreased Maintenance Requirement

Automatic winding machines are reliable machines and thus consume less maintenance compared with manual systems.

Subsequently, it reduces the operational cost.

Longevity

Usually, high-quality automatic winding machines are capital and long-serving for manufacturers seeking to invest their resources wisely.

Accessibility of Support and Spare Parts

Most of the automatic winding machine manufacturers have sound support services besides available spare parts, all for easy resolution of possible faults and minimum downtime.

Safety Features in Automatic Winding Machines

Integrated Safety Devices

One of the prime concerns in the design of automatic winding machines has been safety.

Most of these machines have built-in safety features that protect the operator from becoming endangered while machine operation.

Reduced Operator Hazards

Due to the fact that all processes of winding are controlled by machines, there is very little manual handling.

Thus, the possibility of injuries resulting from repetitive actions is reduced.

Assurance of Greater Safety

Mostly, automatic winding machines are made to conform to industry safety standards, thus providing an added comfort to manufacturers regarding regulatory compliance over the operations that they carry out.

Conclusion

Automatic Winding Machines are emerging as the most well-considered machines due to the multiplicity in beneficial features associated with their use such as increased efficiency and productivity, improved precision, cost effectiveness, increased flexibility, and user-friendly automation.

The contribution made by all these advantages clearly places these machines as essential within all possible industries.

Increased productivity and quality will, therefore, directly link to such automatic machines investment for these industrialists. Efficiency is essential in today’s competitive market.

Through their modern-day ideas, automatic winders can add productivity, reduce costs, and eventually drive companies towards achieving their goals.

Welcome into a bright future of manufacturing by putting these modern machines into your operations’ implementation; sit back and watch them work wonders in your factory.