In this day and age of modern manufacturing, the trend is towards the use of smart equipment which is changing the entire employee working in factories.

Smart equipment consists of enhanced performance tools and machineries which contain devices, software and connectivity features that allow devices to communicate with each other and with the main system.

It brings in productivity enhancing factors, cuts down the running costs and most importantly enhances the quality of the products produced.

Smart equipment enables the manufacturers to adjust to the ever changing consumer market quick low rates of resource waste and helps in supply chain management coordination.

In the long run, this change in technology improves operational performance augmenting the growth and sustainability of the development of next generation of factories.

Key Components of Smart Equipment

Devices of the Internet of Things

IoT technologies stand at the heart of smart devices since they allow equipment to connect and exchange information via the Internet.

In addition, such devices measure and track performance, manage machine conditions, as well as monitor and report on the processes of production.

Due to the interlinking of several devices, a manufacturer can build an enabled ecosystem that improves visibility and aids in the decision-making process.

Artificial Intelligence and Machine Learning

Data generated from smart equipment is tremendously large and AI machine learning tools uses these data to detect patterns and make forecasts.

This results to the foresight of potential issues that would lead to breakdowns in machines enabling the factory to prepare for such circumstances, machine scheduling efficiency, machine inspection quality and thus operations smarter and less idle time.

Robotics and Automation

Robotics is an essential component in smart factories since creating robots for performing repetitive tasks improves accuracy and speed.

Robots known as collaborative machines are designed to work in close proximity to a human operator to enhance productivity and acquisition.

Besides speeding up the process, automation also helps in the redeployment of job functions that require more commitment to specialized and innovative service delivery.

Benefits of Smart Equipment in Factories

Efficiency and Productivity Improvements

Smart equipment mobility increases efficiency by reducing human involvement and automating systems.

Using a rollback, they’re able to streamline processes and reduce work dynamics thus enhancing productivity.

This also results in leaner lead times and quality output from the manufacturing process.

And More:

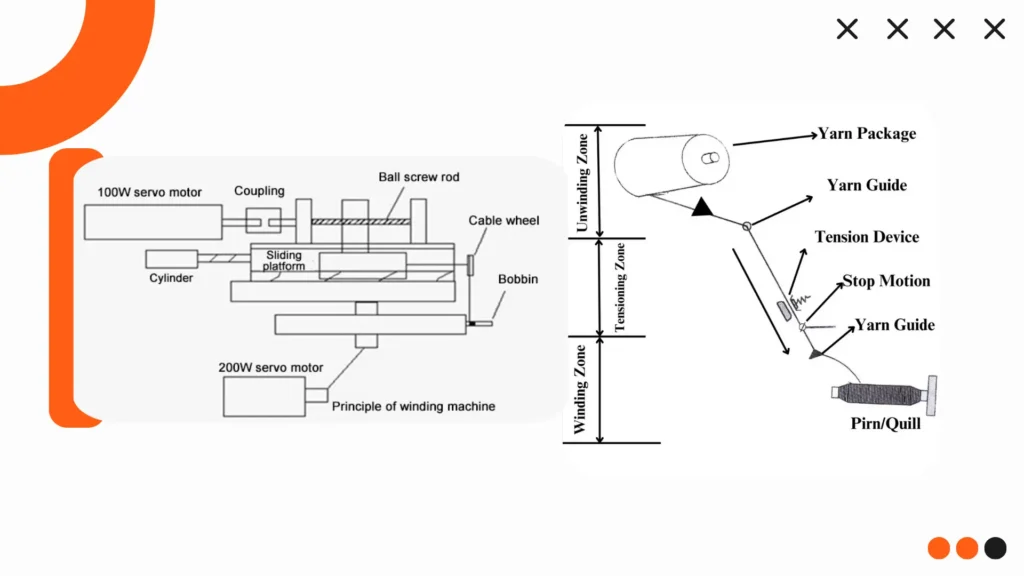

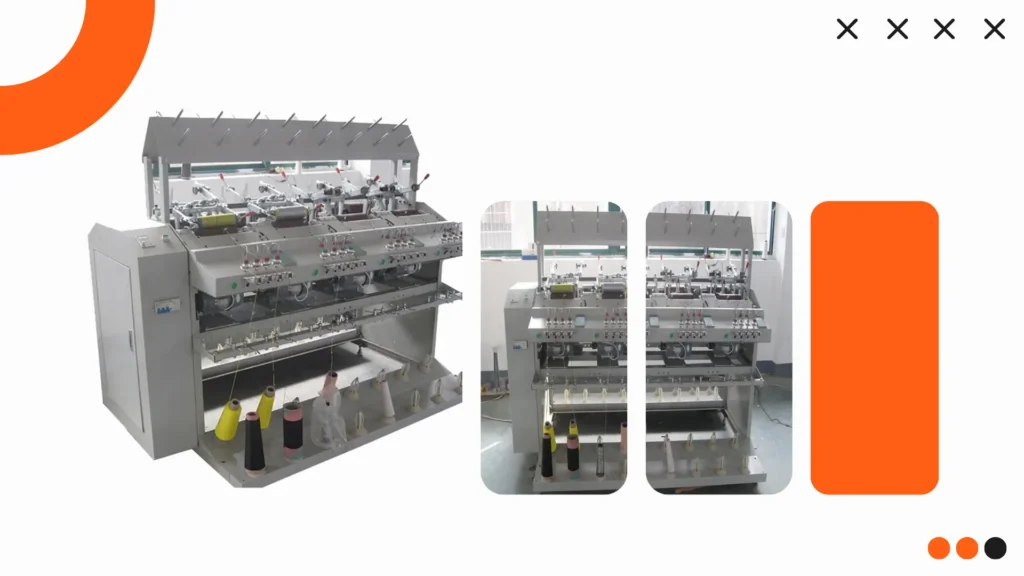

Improving Winding Efficiency in Textile Factories

Improved Product Quality Management

Manufacturing involves many processes where quality control is one of the most important, and smart devices are able to give feedback about product quality in real time.

By equipping the production line with sophisticated sensors and AI analytics, manufacturers are able to identify defects within the production process thereby ensuring that only perfect products are available for sale in the market.

This helps in saving on wastage as well as improving customers’ happiness levels.

Data and Analytics in Real Time

For manufacturers, it is revolutionary to possess real-time information.

Valuable equipment looks more than issuing reports; it helps in decision-making.

Production data analysis allows to see the dynamics, improve resource distribution, and optimize operation mechanisms, which will positively affect the efficiency of work.

Smart Equipment and Workflow Optimization

Simplifying the Processes of Production

Intelligent devices allow coherent amalgamation of distinct manufacturing stages.

Hence, the manufacturers can streamline their operations, lower the lead times and improve the efficiency of the whole process by automating the flows, and also enabling the machines to communicate effectively.

Minimization of Downtime

Manufacturers often incur losses when there are unexpected downtimes.

Smart equipment employs predictive maintenance practices aimed at failure prevention.

By monitoring the state of a machine, it is able to predict machine failures meaning that unplanned downtime is reduced significantly.

Also Read:

Strategies for Reducing Downtime in the Production Process

Enhanced Management of the Supply Chain

Smart equipment improves efficiency in managing inventories by enabling the manufacturers to track stock within the production process using real time data.

This enables manufacturers to balance and maintain their stock levels, curtail carrying costs and increase their order turn around ratio which result to minimal costs and more satisfied customers.

Cybersecurity in Smart Factories

Risk Assessment

When it comes to the identification of weaknesses or gaps in the network and equipment, performing assessments on a periodic basis will suffice.

This means that all the devices connected will be examined and assessed as to their level of security as well as potential sources of intrusion.

Manufacturers are supposed to allocate security strategies depending on the level of the threat in the context of the exposed vulnerabilities with regards to the systems with the capability to change them being protected.

Network Segmentation

Network segmentation is the strategic practice of incorporating different sections of a factory’s network into ‘zones’ that suppress respective section of the system.

The establishment of such secure zones around major machines and critical data protects the entire network by ensuring that a failure or breach of security in one zone does not cause an effect to the other zones.

For instance, production apparatus could be pushed away from the administration systems therefore reducing the chances of interference between data or processes.

Data Encryption

Data encryption plays an important role in the aspect of cyber security, which is to say that it keeps data away from unwanted parties.

There are two ways of securing information, the first one is when the information is moving around the network and the second one is when the information is dormant and stored somewhere.

Doing this is very crucial in the manufacturing sector especially in keeping its trade secrets as well as the clients’ information protected as any compromises will come at a huge cost both financially and in the companies’ image.

Predictive Maintenance in Smart Manufacturing

Real-Time Monitoring

Real-time monitoring means employing sophisticated sensors, and IoT devices to observe the performance, health management of equipment machineries over a given time period within the process of equipment construction.

These devices measure and record operational parameters such as temperature, vibration, pressure, etc.

This real-time diagnostic monitoring ensures that the equipment condition is known to the manufacturers instantly, hence any deviations can be acted upon straight away.

Data Analytics

AI and machine learning aided advanced analytics have a central role on efficiency maintenance of smart equipment’s large data storage capabilities.

Such solutions can store and process data from the past and the present to detect tendencies or irregularities that would highlight possible faults.

With the help of predictive analysis, it becomes possible for the manufacturers to make maintenance decisions with the raw data.

Predictive Algorithms

Predictive algorithms are those whose outputs depend on the historical performance data from the machine and real-time readings from cluster of sensors to predict when that machine may not be functioning effectively.

By making use of mathematical and computational based models and analytics method, these algorithms are capable of giving maintenance forecasts that will help in maintenance scheduling effectively.

The transformation of maintenance from just dealing with a fault to schedule the works after the fault has occurred is all due to factors advanced due to technology.

This change enables manufacturers to rectify potential problems beforehand, before they become serious issues, thus preventing any non-production closed loops.

Cost Savings

Arguably the most important advantage in favor of predictive maintenance is the capacity to save a good amount of money.

Because of less unplanned equipment down time and use of machinery for as long as its designed, maintenance expenditures can be easily controlled.

Additionally, because of predictive maintenance, scheduling of resources is more effective when it comes to limiting resource conflicts because maintenance works can be done in off-peak times eliminating unnecessary interruptions and enhancing the productivity of the firm.

Challenges of Integrating Smart Equipment

Initial Monetary Commitment and Expenditures

Despite the fact that the utilization of smart appliances is advantageous, most manufacturers are unable to make the requirement of the upfront investment.

The transition should also be made easier by looking at the cost- benefit ratio over a longer period of time and considering other sources of funding.

Possibility of Including Current Systems

Challenges exist in the integration of different components due to the introduction of smart elements.

The manufacturers needs to evaluate the retrofit solutions understand what’s required and carry out the necessary reconstruction to ensure all the systems can communicate and exchange information effectively.

Workforce Adjustment and Education

Change from traditional equipment to Smart equipment means the company needs a new level staffing structure as well as the current workers reskilling.

Training is very important in that the employees have to learn new ways of doing things in a smart factory.

How to Choose the Right Smart Equipment

Investigating and Analyzing Requirements

Investing in intelligent machinery necessitates performing a full evaluation of the individual requirements of your factory.

What problems will you face, what are the aims of production, and what are the possibilities of employing technology for the same?

Evaluating Technology Providers

The effective execution of the system depends to large extent on the selection of the right technology provider.

Opt for those that have been tested, offer extensive after sales support, and have products that are compatible with that of the factory.

Planning for Growth Trends

When opting for intelligent devices, their future growth must be taken into consideration.

The system should be flexible in case the business moves a notch higher or new technologies are incorporated into the existing processes.

Conclusion

To highlight once more, smart equipment comes with several advantages such as optimization of operations, enhanced quality management and sophisticated data processing.

If they harness such capabilities, manufacturers will be able to redevelop their business operations to compete in an adaptive environment.

In the dealings of manufacturing, it is a must to accept smart technologies. This is different from saying that it is advisable to do so.

Firms that adopt smart equipment will not only enhance their operating efficiency but will also prepare for what is coming.

Through the implementation of cutting-edge technologies, manufacturing industries can adopt more flexible, faster and creative business modes.

If you are ready to begin a journey of change within your factory then smart technologies should be an area of focus.