Automatic winding machinery performs a key function in many sectors. Textiles, electronics and manufacturing, all depend on these tools. They automate the coiling procedure.

This enhancement vastly improves efficiency. It also ensures a consistent procedure in manufacturing.

The requirement for these machinery devices is experiencing steady increase. This makes it ever more critical for organisations to grasp how to choose the appropriate model.

The aim of this reference is to provide you with knowledge. This will enable you to make educated choices.

This, in turn, will allow you to improve the functioning of your business. It will also increase productivity by a considerable margin.

Importance of Automatic Winding Machines

Automatic winding machines, they are essential. They serve crucial functions for a variety of causes. First they create speed. This new speed allows companies to meet increased demands.

They can do this without lowering quality they provide. Second these machines lower labor costs. This reduction happens by decreasing dependence on manual labor.

Society places a critical weight on uniform winding. It is important for different entities. These include coils, yarn and wires. Any deviation from this uniformity can cause issues.

Automatic winding machines ensure this uniformity. Every product will match needed specifications. This can significantly decrease defects. Moreover it boosts the overall quality of the product.

Overview of Buying Considerations

When making choice to buy an automatic winding machine, factors need to be considered. This helps to find what’s best for your specific needs. Consider the following. This includes:

Functionality

Evaluate the tasks you need the machine to handle. Make sure it can manage necessary materials and winding styles.

Range of Features

Look out for machines that propose advanced characteristics. These are such as programmable settings, sensors and automation capabilities. These can boost flexibility and efficiency.

Brand Reliability

Research brands known for their quality. Also for their customer service. A brand with good reputation often points towards a product that you can rely on.

Budget Constraints:

Set up a definite budget. Inquire into possibilities within that range. This means considering cost. It also relates to features and quality you desire. Striking a balance is key.

Key Features to Look For

And More:

- Essential Factors to Consider When Choosing an Automatic Winding Machine

- A Comprehensive Comparison of Automatic Winding Machines: Efficiency, Accuracy, and Reliability

Construct Quality and Endurance

Considering automatic winding machine, one must ponder upon build and durability.

A well-built machine can survive the trials of incessant operation. This is crucial in high-volume production settings. High-quality materials lower probability of breakdowns.

This leads to less maintenance costs and longer operational lifespans. Seek features like reinforced frames. Look for high-grade components that can endure wear and tear.

Number of Programs and Settings

Versatility becomes pivotal when selecting winding machine. Opt for the model with multitude of programs.

One with many settings is also ideal. This kind of model tackles a variety of differing winding requirements. It handles different materials effectively. Also accommodates various spool sizes effortlessly.

Such versatility allows enterprises to cope with changing production demands. No need for additional equipment investment.

This enhances the value of the machine over time. It also makes the machine more cost-effective.

Noise Levels

In production environment the noise levels have importance. This is an essential consideration. Machines that function with minimal noise boost comfort in work.

They enhance employee productivity. Too much noise causes distraction. It has the potential to raise safety concerns.

It is vital to consider machines that noise operate quietly. This is key to maintaining a pleasant work environment.

Size and Design

Physical dimensions and design of machine play critical role in workspace efficiency.

It is important to ensure machine fits well within production area. The design of machine should allow for easy operation and maintenance.

A well-designed machine can improve workflow. It can be integrated more seamlessly into existing production line.

Top Brands in the Market

Overview of Top Brands

A myriad of brands hold recognition for manufacturing superior quality automatic winding machines.

A pursuit of these brands merits your attention. It can help you discern which brands provide premier technology. Also, it will help you judge which offer the best features to meet your needs.

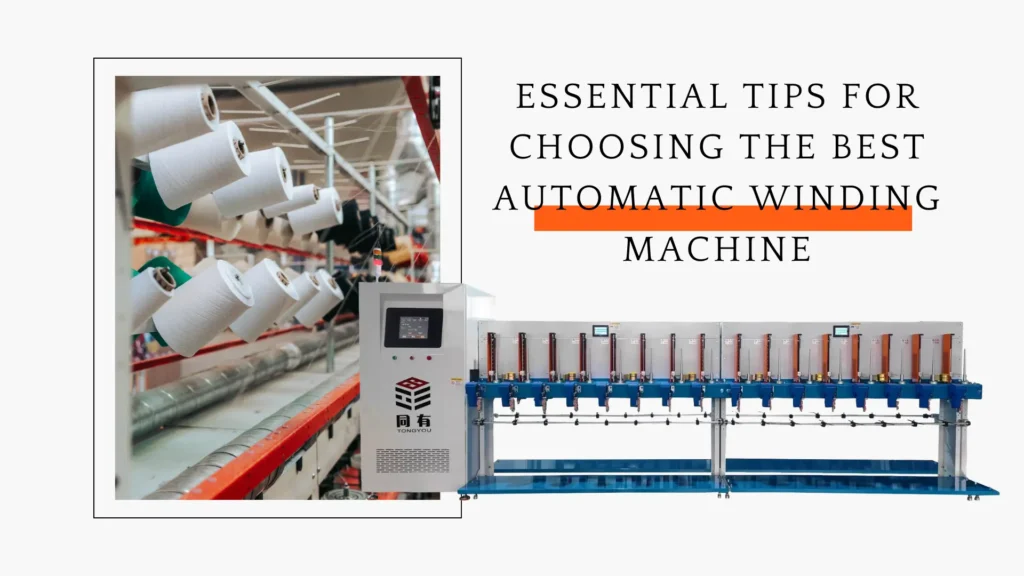

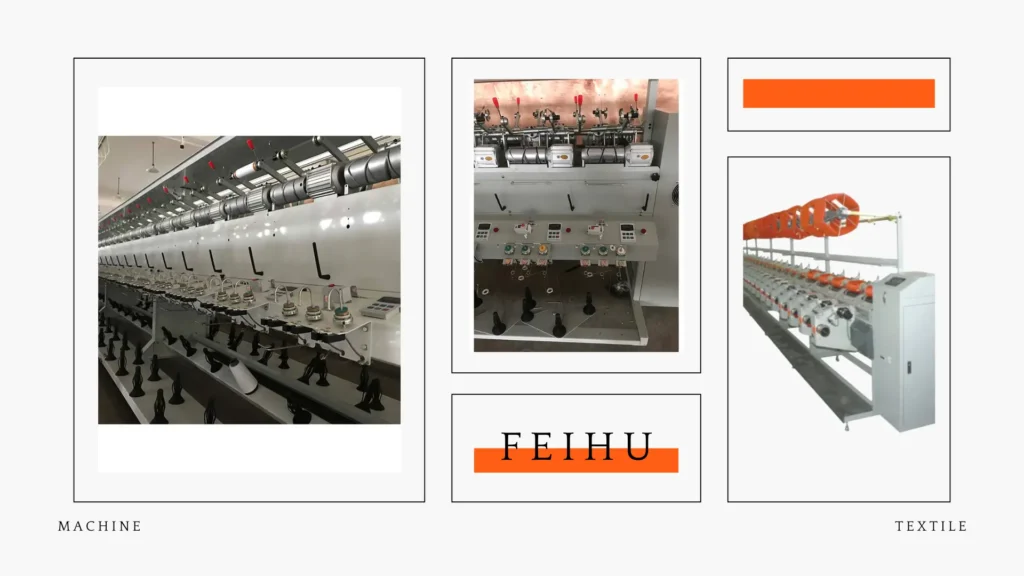

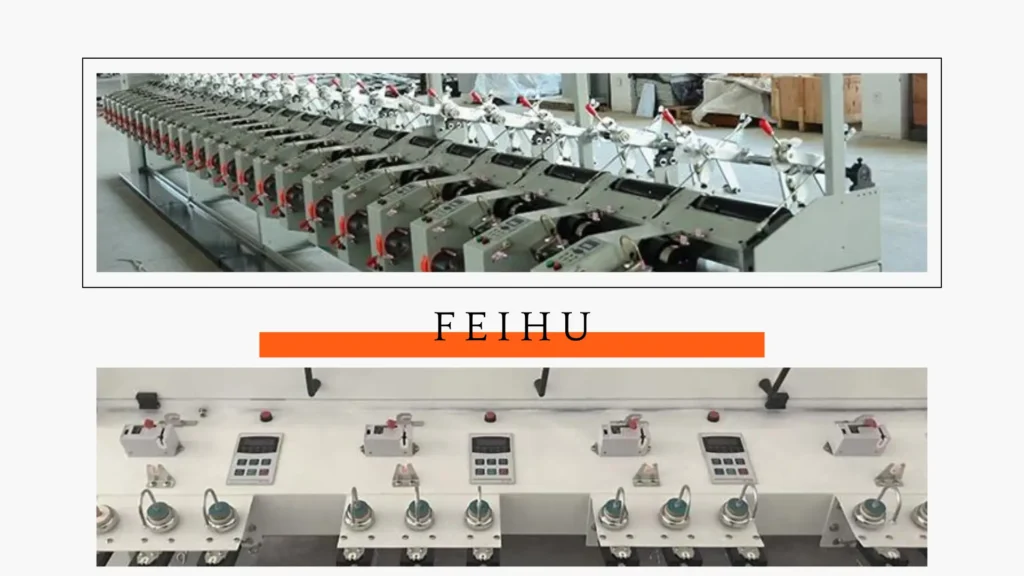

Zhejiang Feihu Machinery Co., Ltd.

With its establishment in 1995 Feihu has soared to leadership in textile machinery innovation.

This brand sets its sights on enriching the traditional textile production. It does so by integrating energy-saving technologies. These technologies augment efficiency and production quality.

Guangdong Huaneng Electric Equipment Co. Ltd.

This brand stamps emphasis on crafting machines. It’s about machines that use less power and at the same time, maintain top-notch performance. Their dedication to energy efficiency is appealing.

It appeals to manufacturers desiring to slash operational costs. And it also appeals to those concerned with lessening environmental impact.

Zhejiang Jinzhu Machinery Co., Ltd.

Famed for user-focused approach Jinzhu Machinery concentrates on comfort and security in machine design.

Their models tout various safety aspects. They aim at creating a safer environment for operators.

Brand Reputation and Customer Feedback

Exploring reputation is important in the context of each brand. It is centric to understand.

Customer feedback along with testimonials are of significant value. They offer understanding of reliability. They also provide comprehension of performance of machines.

Brands that consistently get positive reviews will likely deliver quality goods. They are likely to offer outstanding customer service.

It is always good. Interacting with current users is useful. Reading reviews is essential.

These actions can help you judge overall satisfaction connected with each brand. Jotting the findings down is advisable. For future reference. This is useful.

Comparing Prices and Value

Grasping Price Ranges

Price ranges for automatic winding machines vary widely. The figures are influenced by factors.

These include features. They also include capacity and brand reputation. Budget establishment is crucial before stepping into the marketplace. You must possess a concrete understanding.

Understanding the average price ranges is vital. It helps in the identification of machines. These machines fall within your financial constraints. Moreover, they meet your operational needs.

When shopping for automatic winding machines it is crucial to have a budget. The prices of these machines vary widely.

The factors that influence the prices include features, capacity and brand reputation. Having a clear understanding of the average price ranges is beneficial.

It can help you identify machines that meet your needs. Additionally, they should fall within your financial constraints.

Factors Influencing Cost

Several factors. They can influence the cost of automatic winding machines. Fact of building quality fact of technological features and brand reputation are all significant. They all play important roles.

Higher-priced models often offer advanced functionalities. These include enhanced automation.

They also include better precision and longer warranties. These factors may justify investment. This is especially for larger operations.

Best Value for Money Options

In search of top value for money look at machines. Machines that strike balance between features, durability and cost.

Mid-range models sometimes provide superb performance without the higher price tag. The tag associated with premium brands.

Conduct thorough research. Conduct comparisons. Options that offer great functionality can be revealed. All at a reasonable price.

User Reviews and Recommendations

Importance of Consumer Feedback

Consumer feedback is essential. Reviews give true perspective on a product’s performance. They shine light on product reliability.

Such insights are often not visible in product descriptions. With reviews you gain a fuller perspective on potential issues.

Positive reviews could be indicators of a dependable product. However, negative reviews hold their own importance.

They could warn about what to avoid. These reviews might steer you away from certain models.

Where to Find Reliable Reviews

For reliable reviews look to respected sites. Visit forums and trade magazines. These sources focus on machinery.

To get others’ experiences engage in online communities. For example, social media groups and professional forums.

These can offer firsthand experiences. They also provide insights which will help you make an informed choice.

Maintenance and Care for Automatic Winding Machines

Significance of Regular Maintenance

Maintenance that is regular it is crucial. It is especially crucial for maintaining longevity and performance of machines that wind automatically.

Proper maintenance helps in preventing failures. And it helps also, in expensive repairs. Furthermore, it makes sure the machine operates in a smooth manner. It also ensures efficiency.

A maintenance schedule that is proactive is key. It can reduce downtime to a significant degree. It also extends the life of the owner’s investment.

Common Maintenance Practices

An essential practice is the implementation of a maintenance schedule that is routine. It should include the regular cleaning.

Lubrication of all moving parts is equally vital. Inspection of key components it also integral.

Providing training to operators on the best care practices is beneficial for the machinery.

It can help minimize the wear and tear. Detailed records of maintenance activities should be kept. These records prove helpful. They can assist in pinpointing patterns of malfunction.

They can also reveal potential issues. By doing so they prevent any small issue from escalating.

Innovations in Automatic Winding Technology

Technological Progress

New additions in auto winding machines have involved smart tech. One of these is IoT connectivity.

Another is advanced automation systems. Smart tech features offer real-time monitoring on winding process.

It enables data analysis. This analysis in turn increases overall efficiency and productivity. Automation can result in more precise winding. This reduces material waste and enhances product quality.

Future Trends in Winding Machines

Industries are evolving. This evolution will lead to a rise in demand for more advanced winding solutions.

The future may involve more automation. It may also prioritize enhanced energy efficiency. And we may see eco-friendly designs.

Manufacturers will likely direct focus toward developing machines. These machines will meet production needs.

They will also align with sustainability goals. This will make them important in modern production processes.

As the fourth industrial revolution continues, we will see further technological developments. These trends will shape the future of winding machinery.

Conclusion

Conclusively choosing correct automatic winding machine requires understanding its role. You need to understand its unique features. You should also understand how important brand recognition is.

Looking at various price points is vital. You need to look at user feedback too. This helps guide your choice. It makes sure you purchase a machine that fits your operational needs.

It is beneficial to take time for research. This should be done before making a purchase. The process can result in long-term benefits. It is important to keep in mind all the discussed points.

With this you can make a well-informed decision. It can enhance your production capabilities. It should also meet your business goals.

The suitable automatic winding machine can boost efficiency. It can decrease costs. Ultimately, it can increase profit.