Automation denotes use of technology. It does tasks with little human interference.

In textile business this merging is key. Machines and software manage processes.

For instance weaving, knitting cutting and finishing fabrics. This is all done without need for manual work.

Automation enhances efficiency. It also improve accuracy and speed. This, in turn allows manufacturers to produce first-rate textiles at a reduced cost.

Learn More:

- Comprehensive Guide to Sourcing Automatic Winding Machines from China

- Cost-Effective Strategies for Buying Automatic Winding Machines from China

- Improving Winding Efficiency in Textile Factories

The Evolution of Textile Manufacturing

Textile manufacturing has undergone significant changes over centuries.

Advancements like the spinning wheel invention and the power loom introduction have aimed to increase productivity.

RIse of automation has transformed the industry. Manufacturers now can streamline operations.

They can respond quickly to market demands. This evolution continues to shape textiles production. It makes automation a critical component of modern manufacturing.

Why Automation Matters Today

Automation is vital now more than ever in today’s fast-paced market. This applies particularly to the textile industry.

There is a growing need to meet stringent competition. Consumer expectations for quicker turnaround times and higher quality are rising.

Manufacturers in the textile industry have no choice. They must adopt automation technologies to remain relevant. It’s not simply a matter of business improvement.

Automation does improve efficiency of operations. Yet, it does much more. It allows companies to innovate.

It allows them to adapt to changing trends. It ensures sustainability and profitability in the long term.

Key Automation Technologies

Computerized Knitting Machines

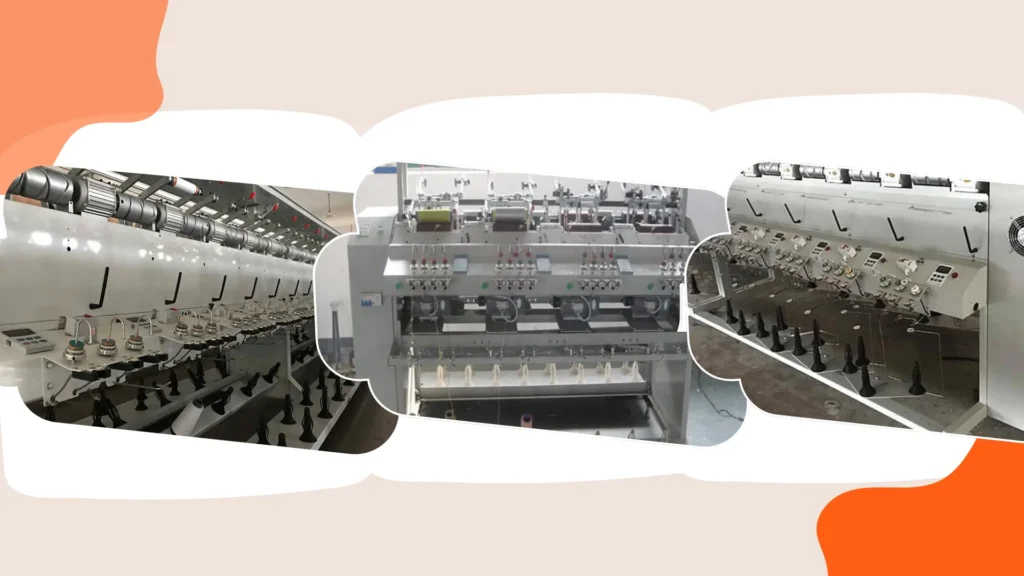

Advanced computerized knitting machines stand as major progress in textile manufacturing.

These utilize programmable software. This software creates complex patterns and designs with exactness.

The knitting process is automated through this technology. Manufacturers can produce tricky textiles faster now. Textiles are more accurate in comparison to employing traditional methods.

This technology is designed for customization and flexibility. It caters to varying market needs.

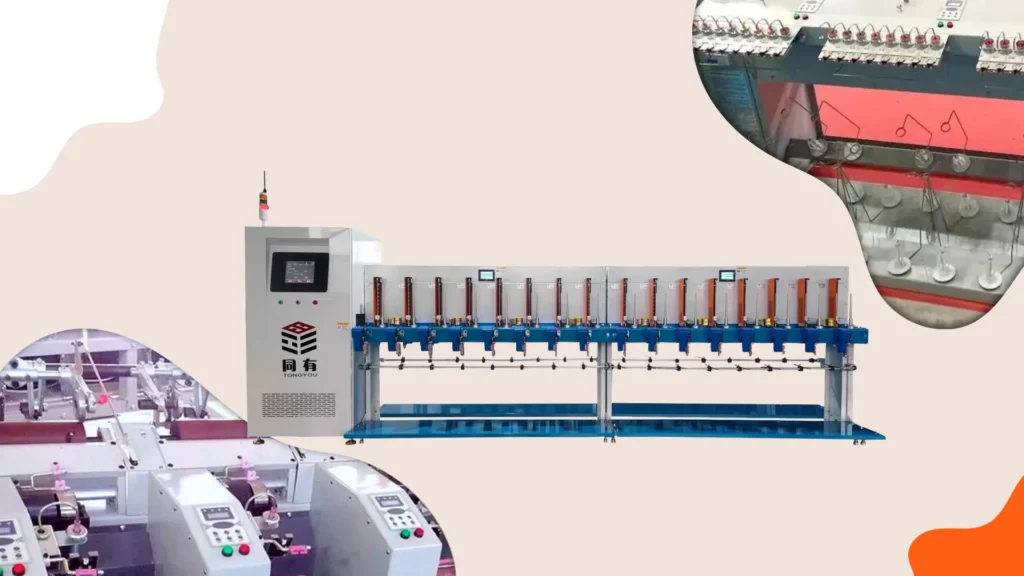

Automated Cutting Systems

Systems of automated cutting raise efficiency in readying fabric. Advanced algorithms and laser technology come into play in these systems.

Fabrics are cut with precision. Waste is minimized. Cut patterns accurately.

Automatic cutting not only hastens up production process. It is also less prone to errors. This, in turn leads to higher quality products.

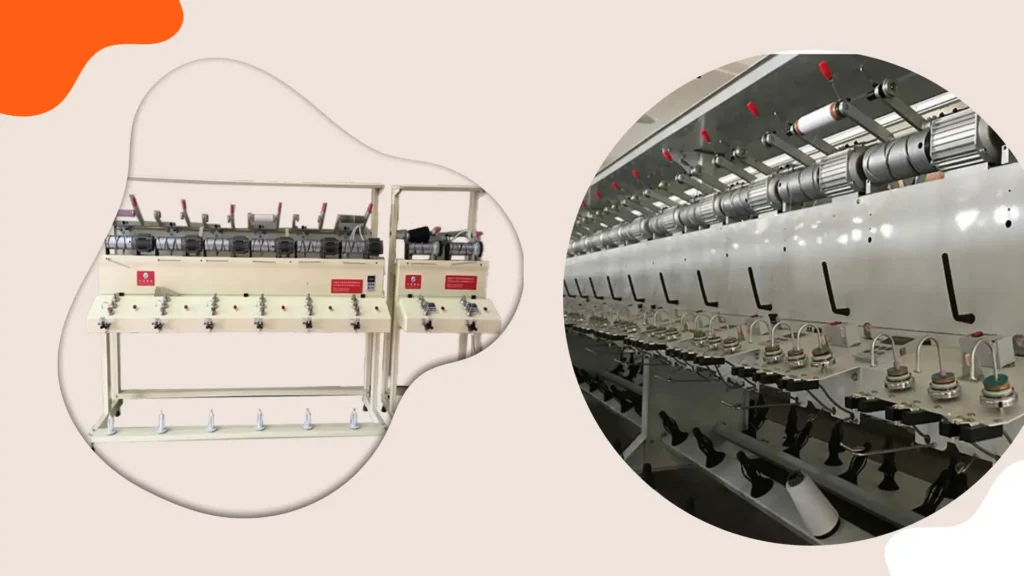

Robotics in Material Handling

Textile manufacturing has experienced a revolution in material handling. This is attributed to robotics.

Gone are the days of manual labor. Present are automated guided vehicles (AGVs).

Also, robotic arms are now common. They transport materials and products. They move these throughout a production facility.

This technology reduces manual labor. Safety is also improved. The risk of workplace injuries is minimized.

Robotics also ensures that materials receive consistent handling. Production efficiency is further enhanced.

Benefits of Automation in the Textile Industry

Enhanced Efficiency and Productivity

Automation’s considerably heightened efficiency and productivity stand as one of its most essential advantages.

Machinery can function nonstop. It produces textiles quicker than human labor. With its 24/7 operational capacity, it results in superior output. Companies can meet consumer demand more competently.

Improved Quality and Consistency

Automation pledges superior quality and consistency in textile manufacturing.

Automated systems sustain precise process control. This aids in diminishing human error and variability.

It is then possible for textile manufacturers to produce textiles. These textiles meet stringent quality standards. This boosts customer satisfaction. It also escalates brand loyalty.

Reduction in Labor Costs

Textile manufacturers can cut labor costs significantly through automation technology.

Machines take care of repetitive tasks. It allows businesses to function with fewer workers.

They can distribute resources more efficiently. This decrease in labor needs saves money.

It also helps workforce concentrate on more skilled tasks. These tasks require human oversight.

Smart Textiles and IoT Integration

What Are Smart Textiles?

Smart textiles are fabrics. They incorporate advanced technologies. These technologies provide extra functionalities.

Textiles can respond to stimuli. Stimuli like temperature or moisture. They may even include sensors. Sensors monitor health indicators. Smart textiles being integrated into textile industry signifies shift.

The shift is towards innovative products. Innovative products that boost user experience. And they open up new market opportunities too.

The Role of IoT in Textile Production

Internet of Things (IoT) has a pivotal role in contemporary textile manufacture. It connects machines. It binds devices to the web. Connectivity paves way for real-time data exchange.

This enables manufacturers to oversee production processes. It allows them to trace their inventory.

They can analyze performance statistics too. IoT integration bolsters decision-making processes. It enhances operational efficiency too. The end result is smarter production environments.

Real-Time Monitoring and Data Collection

Manufacturers collect and analyze real-time data with IoT technology. This collecting and analyzing data capability supports proactive maintenance of equipment.

It enables the manufacturer to minimize downtime. It allows extending machine life.

Real-time monitoring is also a boon. It lets manufacturers identify and resolve issues quickly. The result is that production stays on schedule. It meets quality standards. Sheer perfection.

Sustainability Through Automation

Reducing Waste and Energy Consumption

Automation technologies offer potential. They can substantially slash waste and energy use in textile manufacturing. High-level cutting systems keep fabric waste to a minimum.

This is while automated processes optimize energy use.

Streamlining operations is beneficial. It allows manufacturers to create textiles more sustainably. This coincides with increased demand for eco-friendly practices.

Eco-Friendly Materials and Processes

The use of automation aids in selecting green fabrics. It also simplifies eco-friendly processes.

It does this by effectively handling organic or recycled materials. Therefore, automation promotes sustainability in production.

Other than reducing the impact on environment, this change also aligns with consumer inclination. These consumers desire products that are eco-friendly.

The Future of Sustainable Textile Manufacturing

In grander scheme of things textile production is highly resource intensive. It is also the second most polluting industry.

The textile manufacturing industry has lately shown keen interest in sustainability. Trends do not lie. The demand for eco-friendly fabrics or garments is on the rise.

The main winners in this movement will likely be the companies able to reform their operations.

Adopting sustainable practices is essential. Yet, it is not an entirely straightforward task. It requires significant changes in production line. From raw material sourcing to shipping, everything needs modification.

Challenges in Implementing Automation

Initial Investment Costs

Benefits of automation are significant. However, costs for initial investment may be a barrier.

This is especially true for many textile manufacturers. Automated machines and systems of high quality require significant capital. Smaller businesses may find this capital requirement to be challenging.

Yet, this investment should be seen as a long-term strategy. It can lead to significant returns over time.

Workforce Adaptation and Training

Move to automation presses for workforce adaptation. It also calls for training. New skills could be necessary for employees. These skills could operate advanced machines.

Machines that are complex. Also advanced systems. These skills need to be effective. Training programs that are comprehensive become necessary. They are essential to smooth transition.

The transition of staff into new roles. And for use of technology to its full potential. It is paramount.

Maintenance and Technical Support

Automated systems need regular maintenance. They need technical support too. This ensures efficient operations.

Manufacturers need to put in place reliable support networks. These address technical issues quickly.

Investing in strategies is necessary for maintenance. It helps to reduce downtime. It also ensures that production processes are uninterrupted.

Case Studies of Successful Automation

Leading Companies in Textile Automation

There are several companies. These companies have implemented automation technologies.

Success has been achieved. This is through enhancement of their manufacturing processes. For example, major textile producers are included in these companies.

Computerized knitting machines have been integrated. Automated cutting systems are a part of these processes.

These have led to increased productivity. That’s not all. Waste has been reduced.

These case studies are valuable examples. They are for others looking to invest in automation.

They show that success is possible. These are from some of the leading companies in textile automation.

Innovations That Have Made a Difference

Innovations in automation are numerous. They include robotic handling systems among others.

IoT integration is part of these innovations too. These have made a significant impact on textile production.

Companies that embrace these changes often see improvements. Efficiency improves. Quality improves. Sustainability does too.

These successes can provide motivation. They can inspire other businesses. It might make them explore automation options. It is important to highlight these specific innovations.

They show that change can be for the better. This is especially relevant in the context of automation.

Lessons Learned from Automation Projects

Let’s analyze successes. Also look at challenges. Companies have faced these during their automation journeys. This process provides insights. Learning from these experiences is key.

It helps other manufacturers avoid common pitfalls. It also helps to make informed decisions. These decisions relate to their automation strategies.

The Future of Automation in the Textile Industry

Emerging Trends to Watch

Matters shaping textiles world show significant shifts. These shifts are largely due to automation.

Projections for future trends showcase greater emphasis on technology’s role. The future of textile design and production is becoming more automated.

Current trends display a heavy reliance on technology. It’s evident that automation is a critical part of textile industry’s future.

The integration of smart sensors and AI technologies is becoming more prominent.

These technologies offer a refined understanding of every industrial process. This includes production, distribution and sales.

Predictions for the Next Decade

Looking ahead next decade promises greater advancements in textile automation.

Manufacturers are to adopt smart technologies. This adoption will enhance production efficiency and product innovation.

As consumer preferences shift, sustainable and smart textiles gain favor. Automation will have key role in meeting these demands.

The Role of AI and Machine Learning

Artificial intelligence and machine learning are on the brink of revolutionizing textile manufacturing.

These technologies have the ability to optimize production processes. They also predict maintenance needs and improve quality control.

By using AI and machine learning manufacturers can enhance their capabilities. They can stay ahead of competition.

Conclusion

Summarily automation technologies like computerized knitting machines and automated cutting systems are reshaping textile industry. Robotics also play a role in this sector.

These advances yield augmented efficiency. They bring about quality improvements and a noteworthy reduction in costs.

The textile sector is in a constant state of flux. The need to incorporate automation is crucial for competitiveness.

Manufacturers who put money into these technologies not only improve production potential. They also carve out a path for themselves to succeed in future.

Embracing advanced technologies also changes the landscape. Textile manufacturers can satisfy market needs. They can further contribute towards fostering a sustainable future.