The apparent design for rewinding machines, mainly, has to do with materials like wires, yarns, and other lengths, which have to be coiled into orderly bobbins or spools in a much quicker way.

By automating this process, it not only increases the speed of production but decreases the chances of errors; hence, finding their place in high-volume manufacturing environments.

Winding machines serve in a great variety of capacities, from textile and electronic industries to automotive. They prepare yarns for weaving and knitting in textiles by making the material wind evenly.

Efficiency and accuracy provided by winding machines are therefore quite important in contributing to the overall productivity and quality of products in such sectors.

The aim of the following paper is to provide comprehensive insights into the automatic winding machines in China by describing their history of development, leading manufacturers, technologization, diversification of applications, market trends, and future prospects.

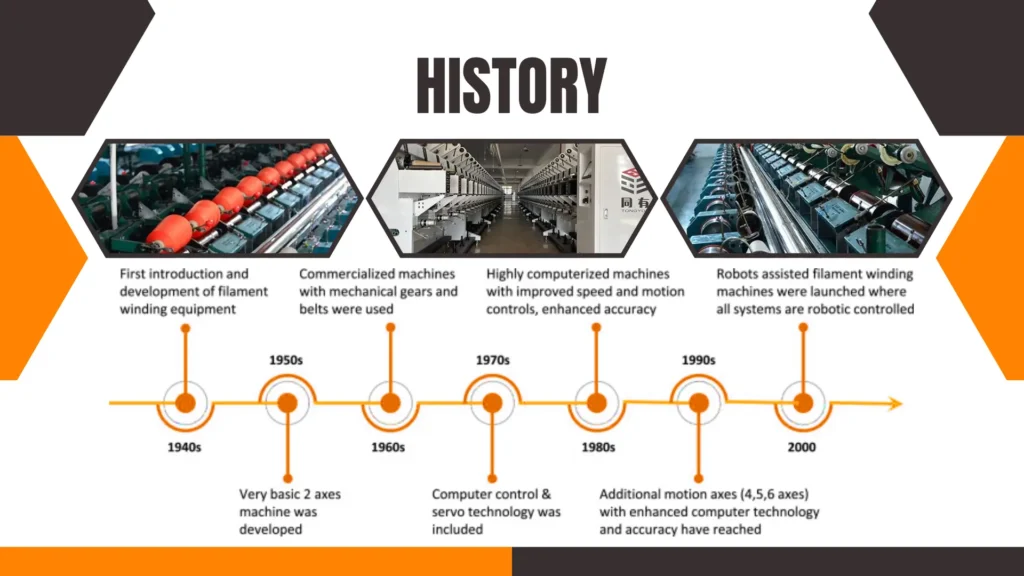

History and Development of Winding Machines in China

Early Innovations in Winding Technology

Winding machines have their early history in manual devices employed in China for coiling materials by hand.

During the advent of industrialization, especially during the late 19th and early 20th centuries, these developed into more sophisticated mechanical devices.

With the advent of steam and then electrical power, machines were built that could mechanize the process of winding with great improvements in efficiency and consistency.

Evolution of Winding Machines over the Years

Over the years, there has been much development with respect to winding machines.

During the mid-20th century, improvements in electronic controls allowed the machines to become programmable-that is, the winding patterns and speeds could be set.

In the late 20th century, improvements in computer technology gave way to completely automated systems that could interface with other manufacturing processes to further simplify production.

Impact of Globalization on the Development of Winding Machines

Globalization has immensely contributed to the growth and advancement in technology of the winding machines in ChinBy facilitating the sharing of knowledge and technology between various countries, the Chinese-based manufacturers have been able to adopt the best practices and innovations around the world.

This has accorded them the edge in producing superior products and hence expanding their frontiers of competition in the global market.

Key Manufacturers of Automatic Winding Machines in China

Snapshot of Major Players

Some of the most reputed manufacturers of automatic winding machines are based in China.

These firms are well-established, with rich experience and quite a good background pertaining to the quality machinery that they have been able to provide for different industries over the years.

Comparison of Products and Services

The products these manufacturers offer range from basic and inexpensive models to high-quality machines with features like automatic tension control and real-time monitoring.

Their services include not only customization options, according to the needs for which a particular client might require the machine, but also full after-sales support to make sure that at all times, the client will be supported and serviced.

Contributions of These Manufacturers to the Industry

This is not only production for these manufacturers but also investment in research and development, inspiring innovation within the industry and setting new efficiency and performance standards.

The quality and customer service in place have added to their reputation and contributed much to the development of the automatic winding machine market in China.

Technological Advancements in Chinese Winding Machines

Innovations in Design and Functionality

Recent designs of the winding machines have taken into consideration two important factors, namely functionality and users’ experience.

Modern machines have designs that make operations and maintenance easier and more ergonomic.

The progress made in materials and engineering has also led to increased robustness of machines and their capability to handle a wide array of materials, thus increasing their adaptability in different manufacturing environments.

Integration of Automation and Smart Technology

Automation and intelligent technologies have given a new turn to the winding machines.

Most of the modern machines come with IoT capabilities, enabling their operation and monitoring remotely.

This means that operators can see real-time performance, make changes on the fly, and even predict.

Improvements in Efficiency and Accuracy

Modern automatic winding machines ensure that productivity and accuracy are significantly improved.

Equipped with a modern control system, the tension during winding is kept consistent, making each coil identical in quality.

Due to increased speed, reduced wastes, and high accuracy, the production process for manufacturers gets optimized, and this helps them cut down on costs.

Applications of Automatic Winding Machines

Textile Industry

The automatic winding machines are fundamental in the textile industries to the preparation of yarns before various processes, which include weaving and knitting.

They ensure that the yarn is wound uniformly, and this is an essential aspect in any form to be able to maintain consistent quality in any production cycle.

This accuracy helps minimize defects on the end products of textiles, hence boosting efficiency.

Applications in Electronics and Electrical Components

Winding machines are essential in electronics that manufacture products such as transformers, inductors, and coils.

Applications here demand a great deal of accuracy because even a slight aberration could further impact the functioning of the finished product.

The capability of the machines to preserve consistent coil dimensions and tension in an unwinding operation ensures that electronic components work reliably in their proper applications.

Role in the Automobile and Aeronautics Industries

Similarly, automatic winding machines find immense applications in the manufacture of complicated parts like wire harness and special coils within the automotive and aerospace industries.

In these industries, literally every part is crucially important to achieve reliability in operation, safety, and adherence to a set of strict regulations.

As such, the precision and efficiency in modern-day winding machines become extremely important for the fulfillment of such demands.

Market Trends in China

Current Demand for Automatic Winding Machines

Automatic winding machine demand is growing in China due to increased automation processes in manufacturing industries, such as car-making, sewing, and woodworking.

The demand will keep evolving with companies striving to be more productive while cutting costs and seeking efficient and reliable winding solutions.

Consumer Preference Analysis

There is an increasing trend on the part of consumers for machines that offer flexibility, ease of operation, besides other value additions such as automation and intelligence.

This is turn is indicative of the greater acceptance of the principles of Industry 4.0 whereby manufacturing companies strive to make their operations as efficient as possible through the use of intelligent machinery capable of adapting to alter production variables.

Influence of Economic Factors on the Market

Economic growth in the country leads to increased investments in manufacturing technologies, further driving the automatic winding machines market.

As businesses grow with expanding operations, modernization increases the demand for good quality winding solutions, therefore creating better prospects for manufacturers in the industry.

Future Prospects for Automatic Winding Machines in China

Forecasts of Market Growth

There are prospects that the market for automatic winding machines will see rapid growth in the times to come as well.

From the point of continuous industrialization, automation, and adopting smart technologies, China will lead the global market for winding machines.

Potential Challenges and Opportunities

Although the outlook is bright, there are going to be many challenges ahead, namely increasing competition from foreign manufacturers and pressures for continuous innovation.

These can also be opportunities for differentiation among manufacturers in terms of better technology and customer service.

Role of Innovation in Shaping the Future

Indeed, those manufacturers who invest in research and development to develop the machine for higher efficiency, versatility, and user-friendliness will be more apt to meet the changing requirements of their customers and stay ahead in the competitive market.

Case Studies of Successful Implementations

Examples of Companies Utilizing Automatic Winding Machines

Several companies have implemented these machines in their production line.

The biggest manufacturer of electronic components is DEF Electronics, which has integrated these automatic winding machines for streamlining the production of the coils.

Benefits Realized from These Implementations

In this way, the introduction of automatic winding machines allowed the studied companies to save considerably by avoiding notorious material waste and increasing the quality of the final product.

The optimization of production processes has enabled them to increase production while maintaining the same levels of quality.

Case Studies: Lessons Learnt

Key examples that can be taken from such case studies include the training of staff to use new machines and how important manufacturers’ support continues to be following their installation.

Ensuring preparedness by employees in dealing with the technology offers full potential and will go a long way in attaining overall operational success.

Challenges Facing the Winding Machine Industry in China

Competition from International Manufacturers

These Chinese manufacturers are competing against international companies with higher technological advances and established reputations.

This would mean that to be competitive, local manufacturers will need to be innovative and emphasize quality while at the same time engaging in effective marketing of their products.

Regulatory and Compliance Issues

There are various regulations and compliance issues where the industry manufacturers of the winding machine may face challenges in trying to keep pace with them.

Coming up to both domestic and international standards requires close watchfulness, impacting production processes and costs.

Need for Trained Manpower and Training

There is an overall shortage of skilled labor. With the winding machines acquiring greater sophistication, the requirement for trained personnel who would be able to operate and service the machines also goes up.

Correspondingly, more investment is needed by the manufacturers regarding training programs in order to generate the required skills within their manpower.

Conclusion

Automatic winding machines have important applications in a wide range of industries, creating great opportunities by improving productivity and achieving higher standards of production.

Their ability to ensure much-needed automation and optimization in today’s manufacturing makes them quite indispensable.

The present blog has discussed the evolution and history, leading companies associated with automatic winding machines, prevailing technological features, various applications, market trends, and challenges found in China for such machines.

In each respect, it signifies the very importance of such machines and how further innovation is required.

As long as China innovates and readjusts itself to respond to the demand of the global market, so does the future of automatic winding machines.

This is a line with great opportunities for growth and development in which manufacturers focused on quality and technological advancements will thrive within the evolving landscape.